Do you have a question about the Central Machinery METAL CUTTING BANDSAW 93762 and is the answer not in the manual?

| Brand | Central Machinery |

|---|---|

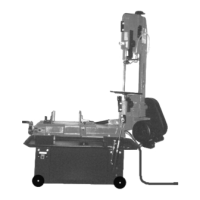

| Model | METAL CUTTING BANDSAW 93762 |

| Category | Saw |

| Language | English |

General safety guidelines and precautions for using the tool, covering guards, keys, work area, and environment.

Specific safety instructions for operating the bandsaw, including eye protection, blade handling, and workpiece security.

Information and precautions regarding the risks of prolonged exposure to tool vibrations and how to mitigate them.

Explanation of grounding procedures for tools with three-prong plugs and requirements for safe electrical connection.

Guidelines for using double insulated tools with two-prong plugs, including polarized plugs and outlet compatibility.

Detailed steps for assembling the main support stand for the bandsaw.

Instructions for attaching the wheels to the assembled stand for mobility.

Procedure for securely mounting the bandsaw unit onto its assembled stand.

Guidance on installing the stock stop assembly for making repetitive cuts of consistent length.

Steps for installing the protective cover over the pulley system of the bandsaw.

Instructions for mounting the spindle and motor pulleys onto their respective shafts.

Procedure for installing and tensioning the V-belt connecting the motor and spindle pulleys.

How to adjust the bandsaw's cutting speed by changing pulley configurations for different materials.

Detailed steps for reconfiguring the bandsaw for vertical cutting operations, including safety notes.

Instructions on how to properly secure workpieces using the bandsaw's vise for stable cutting.

Steps for quickly adjusting the vise to make angled cuts on workpieces.

Guidance on adjusting the stock stop for precise, repeatable cut lengths.

Instructions for setting the correct clearance for blade guide bearings for optimal cutting accuracy.

How to adjust the saw blade's tracking to ensure it runs correctly on the blade wheels.

Steps for properly tensioning the bandsaw blade for safe and effective cutting operations.

How to adjust the rate at which the workpiece is fed into the blade for optimal cutting results.

Instructions for positioning blade guide brackets to support the workpiece correctly during cuts.

Step-by-step guide for safely removing and installing a new bandsaw blade, including tensioning.

Instructions for replacing the V-belt, including pulley selection for different cutting speeds.

Procedure for lubricating the gear box and worm shaft with the specified gear oil.

Guidelines for cleaning the exterior surfaces of the bandsaw using appropriate cleaning agents.

Instructions for safely preparing the bandsaw for storage or transportation, including securing the frame.

Diagnosing and resolving common problems with bandsaw blades, including breakage, dulling, crooked cuts, and unusual wear.

Addressing issues affecting cut quality such as rough cuts, blade twisting, and teeth ripping, often related to speed or feed.

Troubleshooting common motor overheating and mechanical problems, including belt tension and gear lubrication.

Loading...

Loading...