6

OPERATING INSTRUCTIONS

Fitting the Saw Blade

To fit saw blades first raise the safety

guard (5) (if lowered). Use the hex

wrench (10) provided to loosen the

mounting block set screws (4) on the

mounting block (the hex key is located

at the base of the dust extractor

outlet). The blade’s cutting edge

should be facing forward. Insert the

blade’s mounting section into the

Groove in the mounting block and in the small notch in the blade stock until it

touches the bottom of the clip. Then firmly tighten the set screw.

Note: Loose set screws may cause damage to the blade. Tighten the

screws regularly and ensure that the plunger groove is clear and free of

sawdust so that proper blade mounting and set screw clamping can be

achieved.

Hex Key Storage

The hex key (10) is stored at the base of the jigsaw, please return here when

not in use.

Operating the Trigger Switch

To operate the Jigsaw, depress the trigger switch (2). If you wish to use the

Jigsaw continuously, the trigger lock button (1) can be pushed in after the trigger

switch has been depressed. To release the lock button simply push in the trigger

switch.

Using the Jigsaw

Before using the saw and connecting the mains cable make sure the trigger

switch is in the (OFF) position and the safety guard is down. Press the trigger

switch and wait until blade has reached maximum speed. Place the front of the

base plate on the workpiece and line up the cutting line with the line you wish to

cut. Push slowly forward. Keep the base plate flat against the workpiece.

Cutting Metal

An appropriate cutting agent (such as spindle oil, small amounts of soapy water,

etc.) should always be used. If there is no available liquid cutting agent, grease

can be applied to the back surface of the material to be cut.

Cutting Grooves/window Holes

For wood: Align the blade direction with the grain of the wood. Then position the

rounded part at the front of the base plate on surface to be cut, and then slowly

7

lower the saw into material at chosen point of entry. Lower the saw in a pivoting

action until the blade has cut through and base plate is lying flat on material.

For other materials: In materials other than wood when cutting window holes,

firstly use one or similar tool to drill a hole from which initial cutting will begin.

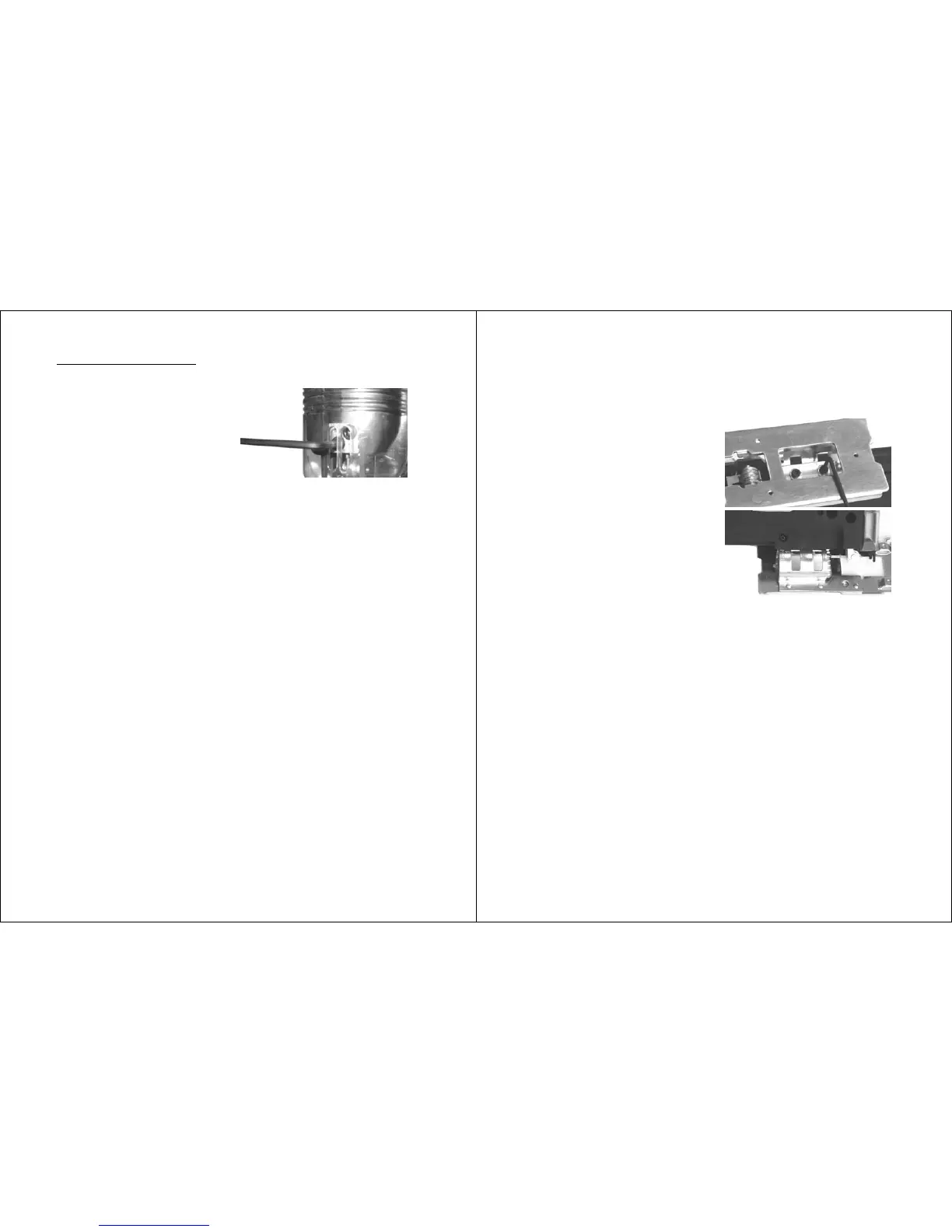

Angular Cutting

For adjustment of the angle of

inclination, loosen the two Allen screws

on the base of saw, see left diagram.

Move the base plate forward or

backwards until the vertical slots in the

base plate align with the two Allen

screws, you will then be able to rotate

the base plate to the required angle.

Angle of inclination numbers is stamped

onto the curved bracket on top of the

base plate to help you set the correct

angle. Check the roller support before

tightening. Firmly tighten the two bevel

setting screws when finished.

Variable Speed Control

Adjust the thumb-wheel to increase or decrease the speed according to the

material, material thickness and blade specification to be used (also possible

during no load operation).

Stroke Rate Selection:

1-2 = low stroke rate

3-4 = medium stroke rate

5-6 = high stroke rate

The stroke rate required depends upon the material and the working conditions:

fast speed to make considerable progress, but slow speed to keep a clean and

finer cut and to avoid straining the machine. Generally, finer saw blades use a

higher speed, coarser blades use a slow speed. Avoid prolonged use at very

low speeds as this may damage your Jigsaw’s motor. After working for a period

at low stroke speed, set the machine running at maximum speed without load

for approximate 3 minutes to cool down the motor.

Pendulum Action Control

The saw blade pendulum action that is adjustable in three steps makes the

optimum adaptation of sawing advance (cutting speed) possible. Cutting

performance and cut appearance of the material to be worked. For each

downward movement, the saw blade is lifted off the material which facilitates

sawdust ejection, reduces the service life of the saw blade. At the same time the

reduction fatigue-free working possible. The pendulum action switch makes

possible the adjustment of the pendulum action in three steps.

Loading...

Loading...