Standard Torque Chart

01-20 79028571 A Rev.

NOTE: Torques are for rigid joints, or joints meeting the

following conditions:

Damage will not occur to joined members of an assembly.

It is desirable to use a higher clamping force.

Fastener threads are NOT lubricated prior to assembly.

The following conditions will require a torque value

different than stated above:

Reduced torque required; non-parallel clamping surfaces,

thick or highly compressible gaskets are used, or when a

higher torque may damage joined assemblies.

Clip nuts, weld nuts, self-tapping hardware, or any

condition that causes reduced thread engagement will

warrant a torque less than stated above.

Special torque values, stated in this manual, must be

strictly adhered to as stated in the specific operation.

NOTE: A number of special torques are used in

assembly of tractors. See list.

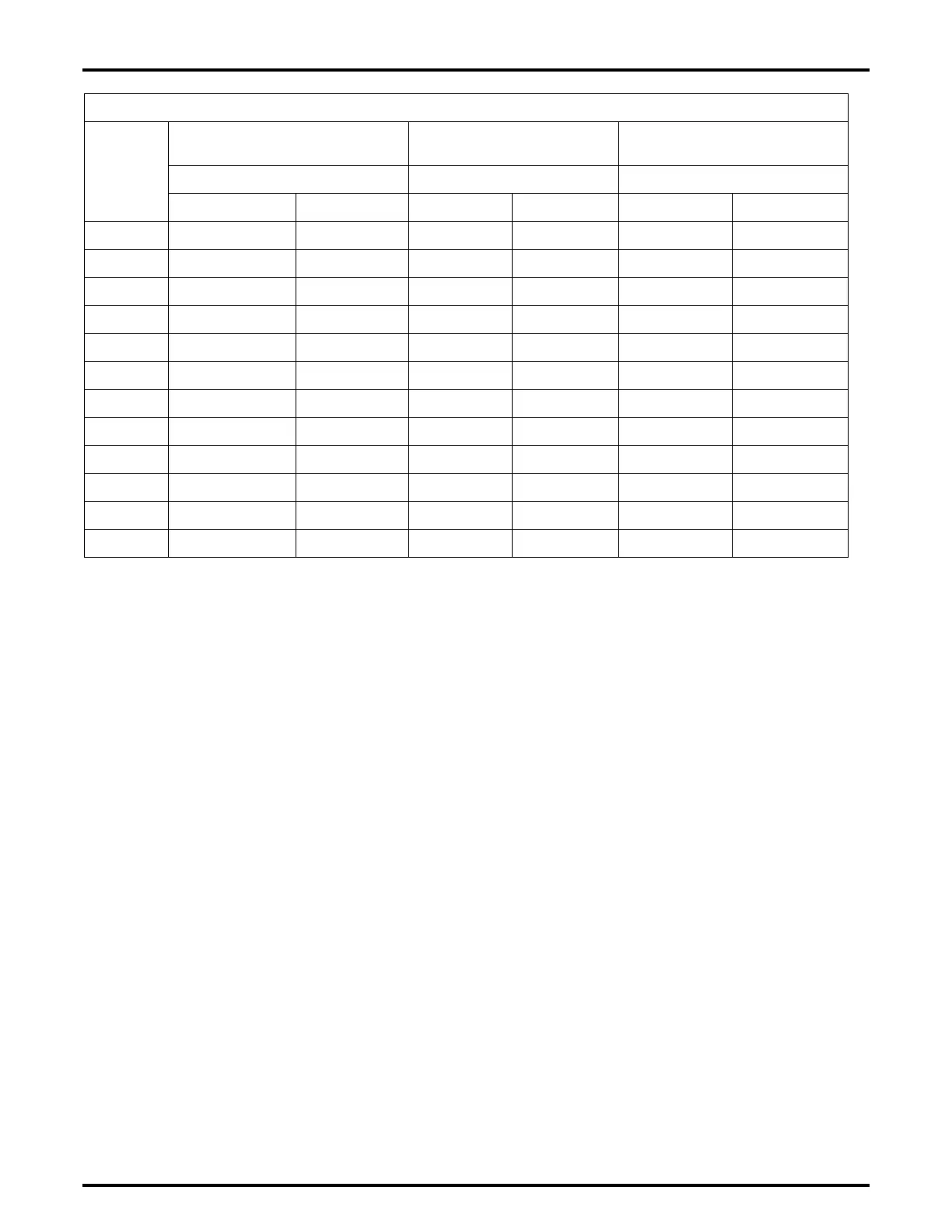

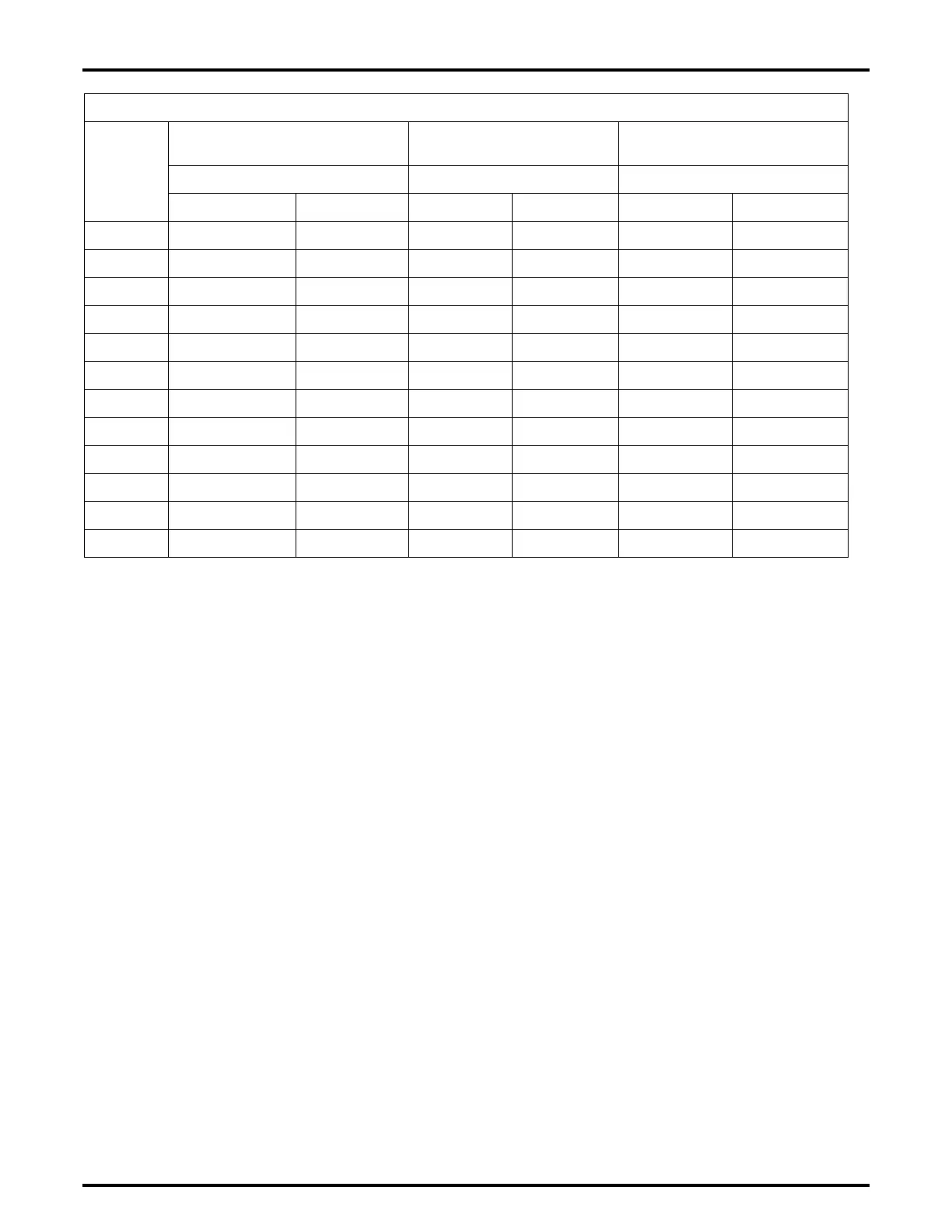

TORQUE CHART FOR INCH FASTENERS (ZINC COATED)

Nominal

Size

Strength Class-

SAE 2 (plain head)

Strength Class-

(SAE 5)

Strength Class-

(SAE 8)

Torque Nm (lbf ft) Torque Nm (lbf ft) Torque Nm (lbf ft)

Min. Max. Min. Max. Min. Max.

1/4 6.8 (5) 8.1 (6) 10.8 (8) 15 (11) 16.2 (12) 21.7 (16)

5/16 13.5 (10) 16.2 (12) 22 (16) 30 (22) 31 (23) 42 (31)

3/8 24 (18) 28 (21) 39 (29) 53 (39) 56 (41) 75 (55)

7/16 41 (30) 46 (34) 64 (47) 85 (63) 91 (67) 121 (89)

1/2 61 (45) 70 (52) 99 (73) 131(97) 140 (103) 185 (137)

5/8 122 (90) 142 (105) 198 (146) 263 (194) 279 (206) 371 (274)

3/4 217 (160) 250 (185) 350 (258) 464 (342) 495 (365) 658 (485)

7/8 - - 569 (420) 759 (560) 800 (590) 1071 (790)

1 - - 847 (625) 1119 (825) 1200 (885) 1580 (1165)

1-1/8 - - 1051 (775) 1390 (1025) 1681 (1240) 2224 (1640)

1-1/4 - - 1491 (1100) 1966 (1450) 2386 (1760) 3159 (2330)

1-1/2 - - 2576 (1900) 3390 (2500) 4121 (3040) 5437 (4010)

Loading...

Loading...