25

FR

ENG

must be carried out using soapy water

or special products. Do not use naked

flames. The conversion to different

gas must be carried out exclusively by

authorized technical personnel.

4.5 REMOVING THE CASING

It is possible to completely disassemble

the shell for an easy maintenance of

the boiler following these simple

instructions:

– Remove the boiler top which is fixed

with pressure plugs.

– Remove the panelboard.

– To remove the door, unscrew com-

pletely the screw fixing the top hinge

and lift the door, removing it from

the fixed plug of the bottom hinge.

– Remove front and back panels by loo-

sening the four nuts which fix them

to the panels side.

– Remove the sides.

4.6 MAINTENANCE

In order to ensure functionality and

efficiency, the device must undergo

annual checks carried out by quali-

fied technical personnel.

4.6.1 Checking and cleaning

the iron cast heat exchanger

Follow the operations below to clean

the iron cast heat exchanger:

– Take off the boiler top.

–

Remove the smoke chamber cleaning

plate by unscrewing the fastening

screws in the EDENA EVOLUTION EF

1.22-1.31 boilers.

–

Remove the smoke chamber comple-

tely unscrewing the two nuts from

the back side and the nut from the

front side of EDENA EVOLUTION EF

1.39÷1.61 boilers.

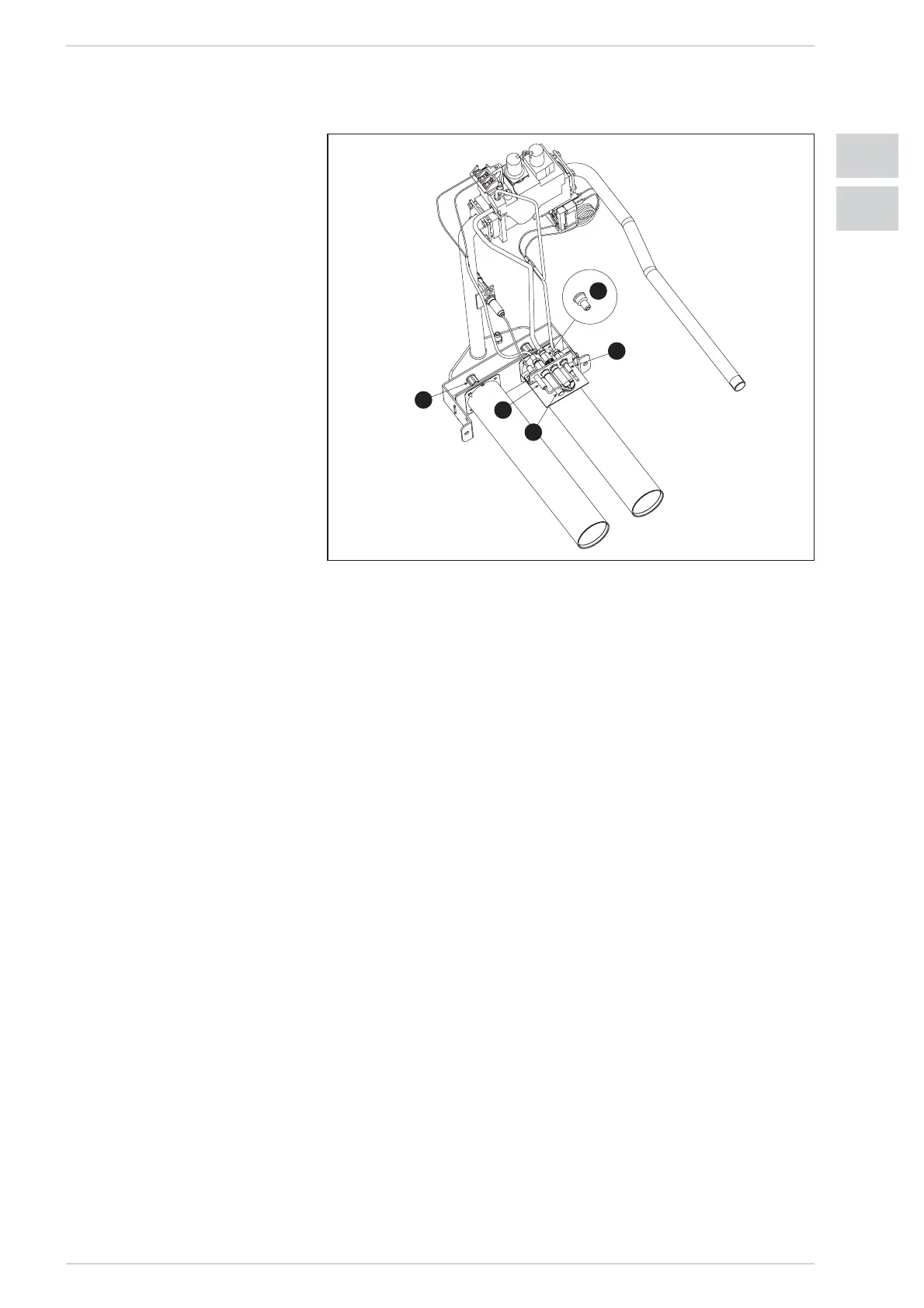

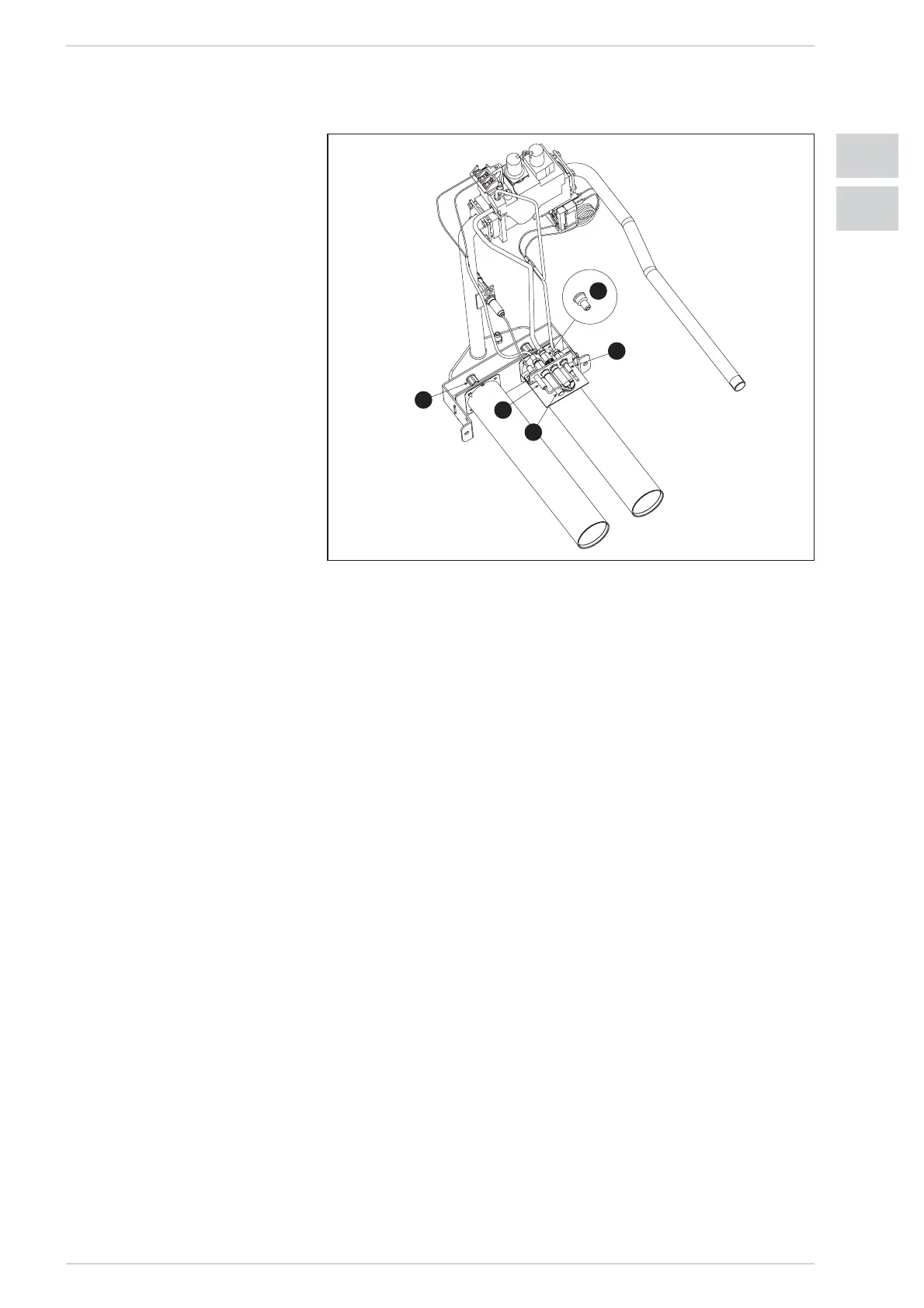

– Extract the burner assembly by

unscrewing the four screws which

fix it to the valve flange.

– With the appropriate brush, reach

down to the rows of plugs of the cast

iron exchanger from the top and

scrape off any scale with vertical

movements.

– Remove the burners from the nozzle

holder header and throw a jet of air

inside them so that any dust can be

removed. Make sure that the top

drilled part of the burners has no

scale left.

–

When disassembling and reassem-

bling the burners be careful not to

force any delicate parts, such as the

thermocouple drill or the ignition unit.

– Scrape off any scale from the boiler

bottom and reassemble all the parts

checking the position of the gaskets.

– Check the stack making sure the flue

is clean.

– Check the correct operation of the

equipment.

4.6.2 Checking and cleaning

the main burner

Address a water jet inwards the bur-

ners so to remove the accumulated

dust. Ensure that the burner perfora-

ted upper part is free from scale.

When disassembling and reassem-

bling the burner, do not force on the

delicate components, such as the

thermocouple, thermopile and pilot

burner.

4.6.3 Checking and cleaning

the pilot burner

Clean the primary air inlet hole and

pilot nozzle with an air jet. Check that

the burner flame licks the thermocou-

ple and thermopile tip completely.

4.6.4 Checking the thermopile

efficiency

If correctly heated, the thermopile

generates the current required for

the gas valve to work. If correctly hea-

ted, the thermopile generates

700/800 mV voltage, which must be

measured using a millivoltmeter on

the two cable connection terminals to

the gas valve.

The operator of the gas valve requi-

res about 300mV voltage.

The poor voltage of the thermopile

prevents the system from working.

4.6.5 Checking the

thermocouple efficiency

If heated correctly, the thermocouple

generates the voltage required for

keeping energised the magnet that

controls the gas passage opening to

the pilot burner. Normally, the ther-

mocouple generates 5/7 mV, which

must be measured using a millivolt-

meter on the two thermocouple con-

nection terminals to the manual reset

safety thermostat. The poor voltage

of the thermocouple prevents the

system from working.

4.6.6 Checking the gas valve

efficiency

Preventive maintenance operations

cannot be performed on the gas

valve. Only the magnetic unit can be

replaced.

Anyway, verify cleanness and remove

Loading...

Loading...