8

Introduction/Operation Product Manual - Perma-Cyl

®

w/ FlexFill™ Piping Option

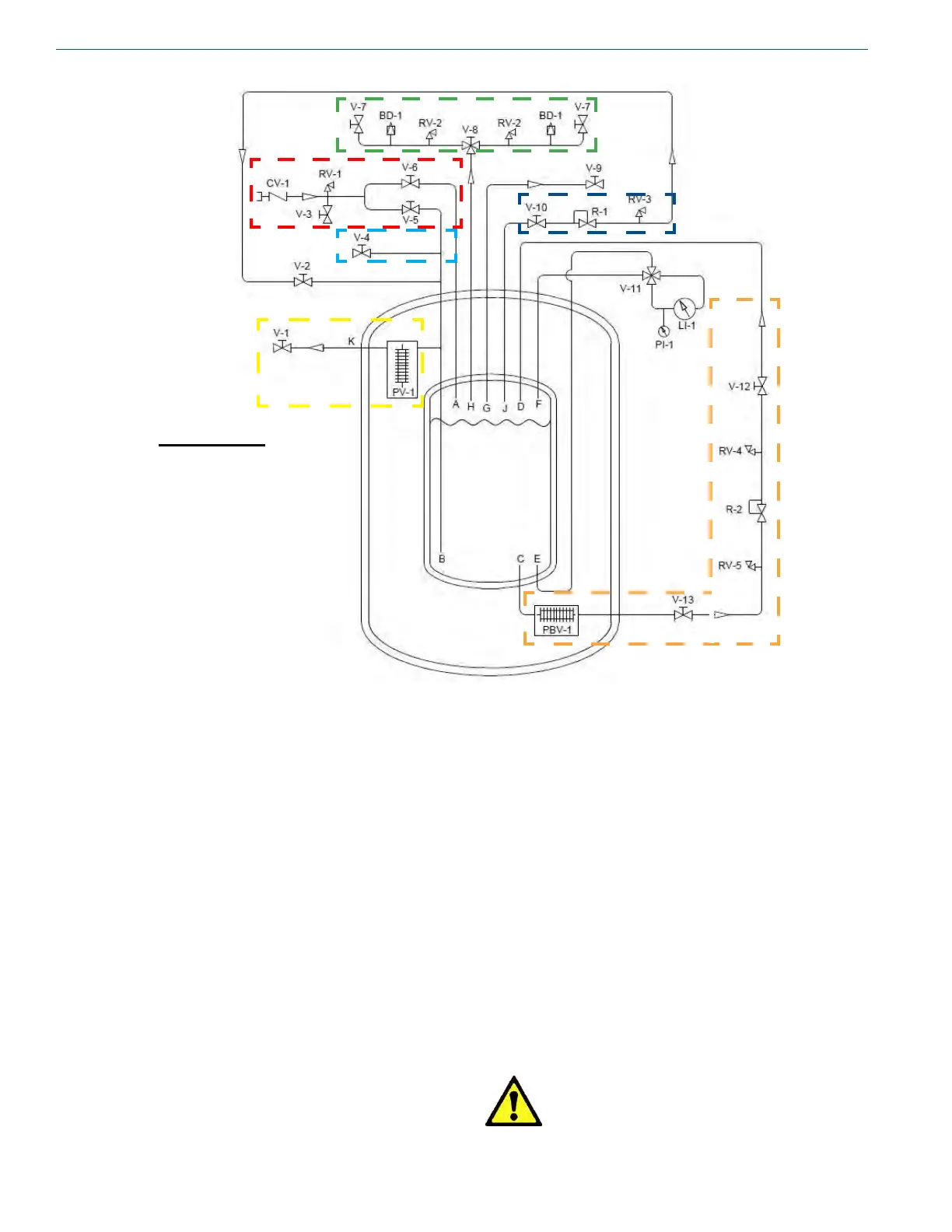

Figure 1 - Schematic for 1000HP/VHP, 1500HP/VHP, 2000HP and 3000HP models.

valves. Product owing into the bottom of the tank will raise

the pressure and product owing into the top of the tank will

lower the pressure. Adjusting each valve properly will allow

the driver to hold a consistent pressure in the tank throughout

the entire delivery.

During a rst ll, only ll the vessel to 75% full to allow

liquid expansion experienced with a new "hot" tank. Each

ll there after can be lled to 100% full. Please refer to

the Installation section of this manual for detailed lling

procedures.

Caution! If liquid can be trapped in the

transfer system, a suitable relief

valve must be installed to prevent

over pressurization.

Color Code:

Fill Circuit

PB Circuit

Economizer Circuit

Gas Use Circuit

Safety Circuit

Liquid Circuit

Primary Plumbing Circuits

(Refer to Figure 1)

Fill

The Perma-Cyl w/ FlexFill has a top and bottom ll circuit

that replaces the top oat assembly so the driver can control

the tank pressure while lling the Perma-Cyl MicroBulk

Storage Tank. The ll circuit consists of a top ll valve (V-6),

a bottom ll valve (V-5), a ll check valve (CV-1), and a

hose drain valve (V-3). The ll line check valve has a service

tting on the inlet side that provides the sole connection for

the liquid delivery vehicle.

The hose drain valve (V-3) can be used to both purge the ll

hose before lling the tank or to depressurize the ll hose

after lling the tank.

The driver controls the pressure in the vessel during the ll

process by adjusting the ow through the top and bottom ll

Loading...

Loading...