25

Product Manual - Perma-Cyl

®

w/ FlexFill™ Piping Option

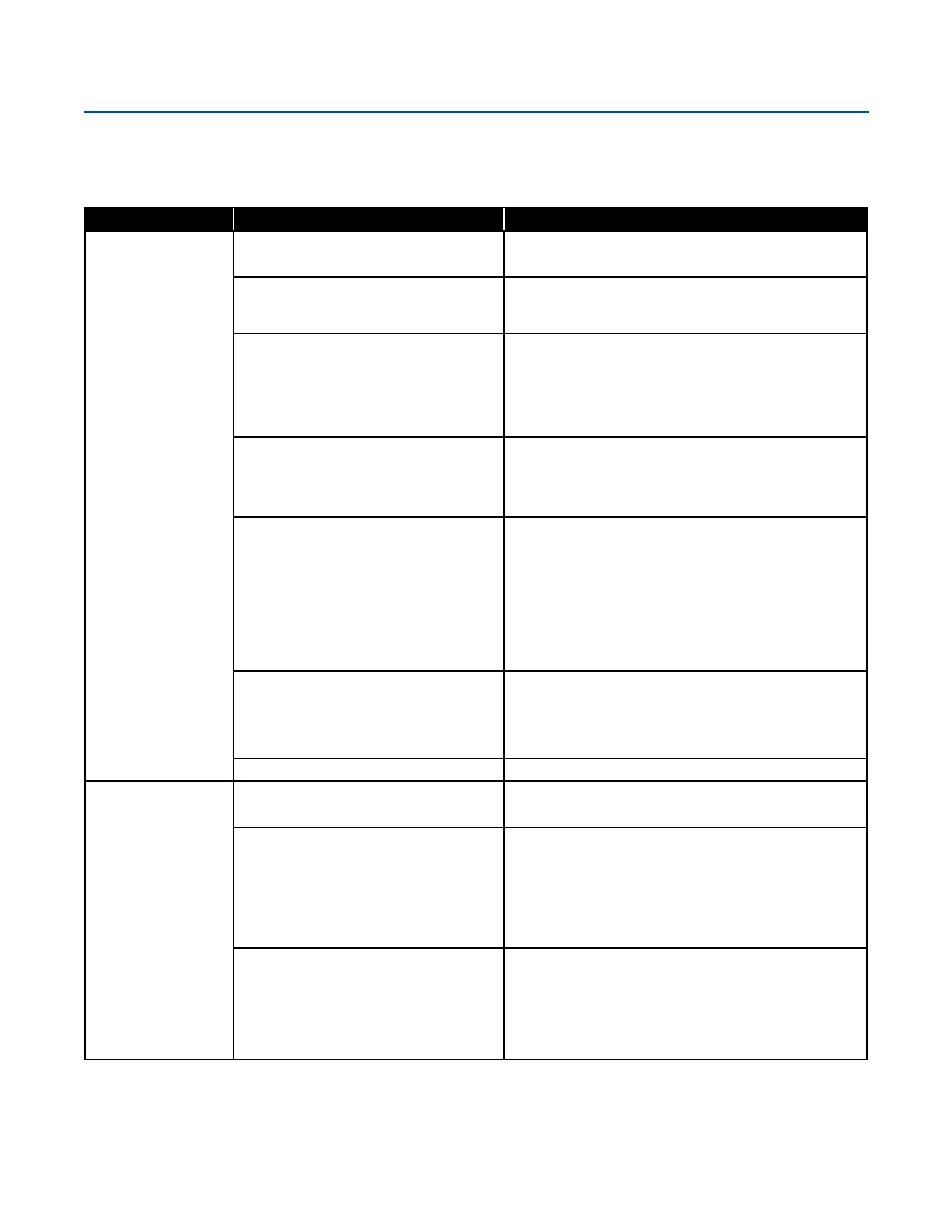

Trouble Probable Cause Remedy

No gas to gas-use

equipment.

OR

Insufcient pressure

to gas-use equipment

Perma-Cyl tank empty. 1. Switch to emergency gas supply.

2. Call gas supplier for delivery.

Gas-use valve to nal line regulator is

closed or other valves downstream are

closed.

1. Open valve or valves, as needed.

2. Insure there is no obstruction in the line or valve.

Pressure builder is not building sufcient

pressure.

1. Open pressure building regulator control valve and

allow pressure to build.

2. Adjust setting on regulator to a higher pressure.

3. If tank pressure fails to rise, see section on low

tank pressure.

Final line pressure regulator set too low

or malfunctioning.

1. Ensure gas use valve is open and tank pressure

is at least 25 psi higher than desired working

pressure of nal regulator.

2. Call service technician.

Inappropriate type of regulator (high-

pressure or 2-stage or too small) installed

as nal line regulator and is not able to

supply sufcient gas ow.

1. Ensure gas use valve is open and tank pressure

is at least 25 psi higher than desired working

pressure of nal regulator.

2. Inspect nal line regulator or its specications to

determine if it has a suitable ow capacity for the

required inlet and outlet pressures.

3. Call appropriate equipment supplier or service

technician.

Gas supply line, hose, or network

contains excessive pressure drop.

1. Check line for sufcient diameter.

2. Remove all unnecessary bends, elbows, reducers,

and small diameter valves.

3. Check for leaks in the gas supply line.

Unknown 1. Call service technician

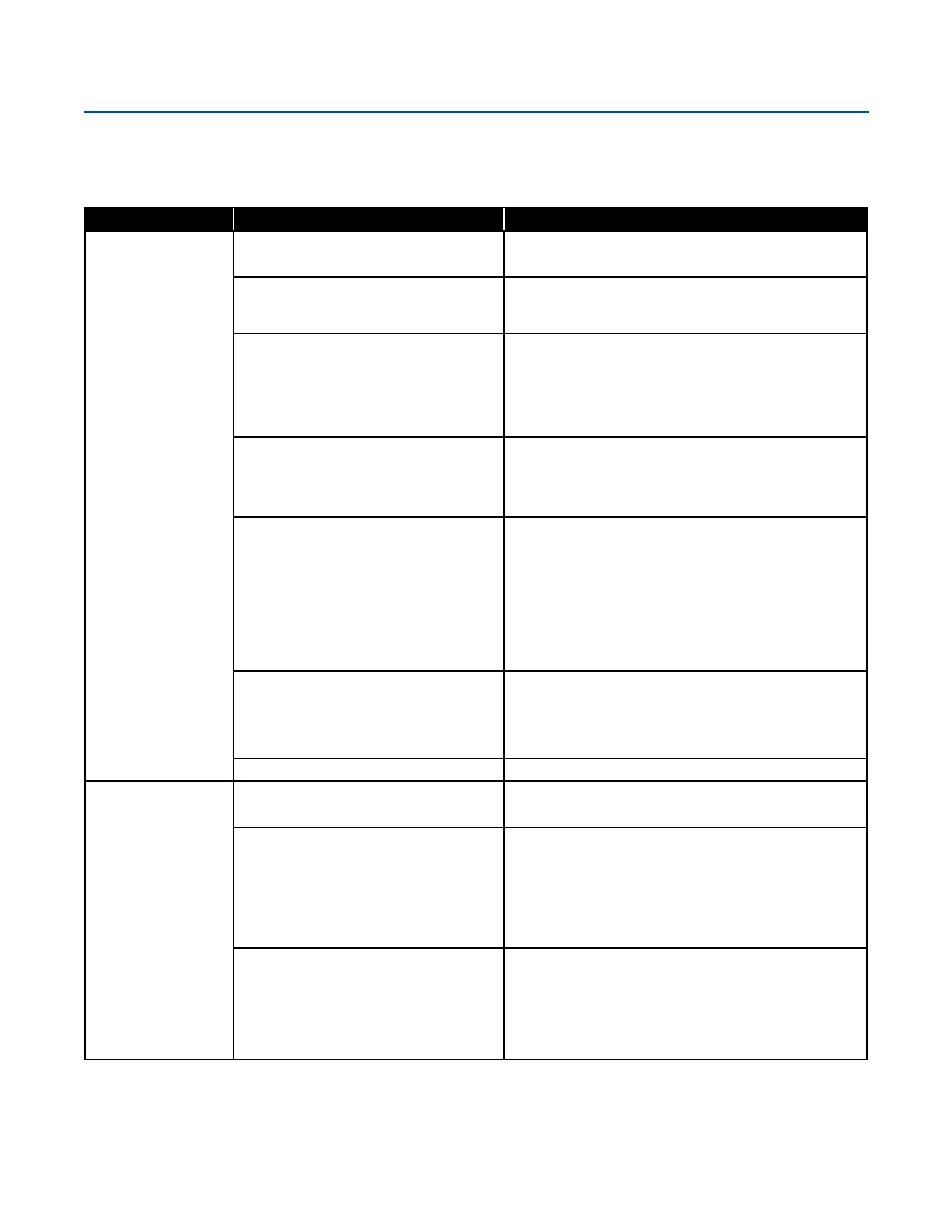

Frost or ice on sides,

bottom, top-center

and / or plumbing of

tank.

Normal condition during and following

gas use, liquid use or lling.

1. None

2. User to check tank for frost / leaks before use.

Tank is being used for continuous ow

application and is not receiving sufcient

ambient heat to melt the frost or ice.

(Tank may have heavy ice build-up

continuous ice or frost.)

1. Move tank to a warmer location.

2. Add additional environmental heat and / or warm

airow to warm outer piping, components and

sides of the tank.

3. Add switchover system to allow tank to rest and

warm up when not in use.

Leak in gas supply lines, gas-use

equipment, or tank plumbing. (Frost is

present on tank even after an extended

period with no gas or liquid use.)

1. Evacuate and ventilate room.

2. If possible, locate and correct leak,

3. User to check tank for frost / leaks each morning

before starting gas use.

4. Call appropriate equipment service technician.

Troubleshooting

The following table is arranged in a Trouble/Probable Cause/Remedy format. The probable causes for specic problems are

listed in descending order of signicance. That is, check out the rst cause listed before proceeding to the next.

Loading...

Loading...