20

Installation Product Manual - Perma-Cyl

®

w/ FlexFill™ Piping Option

Photo 15 - Wall Box

Connections on the wall box are provided for the vent line,

liquid ll and relief line.

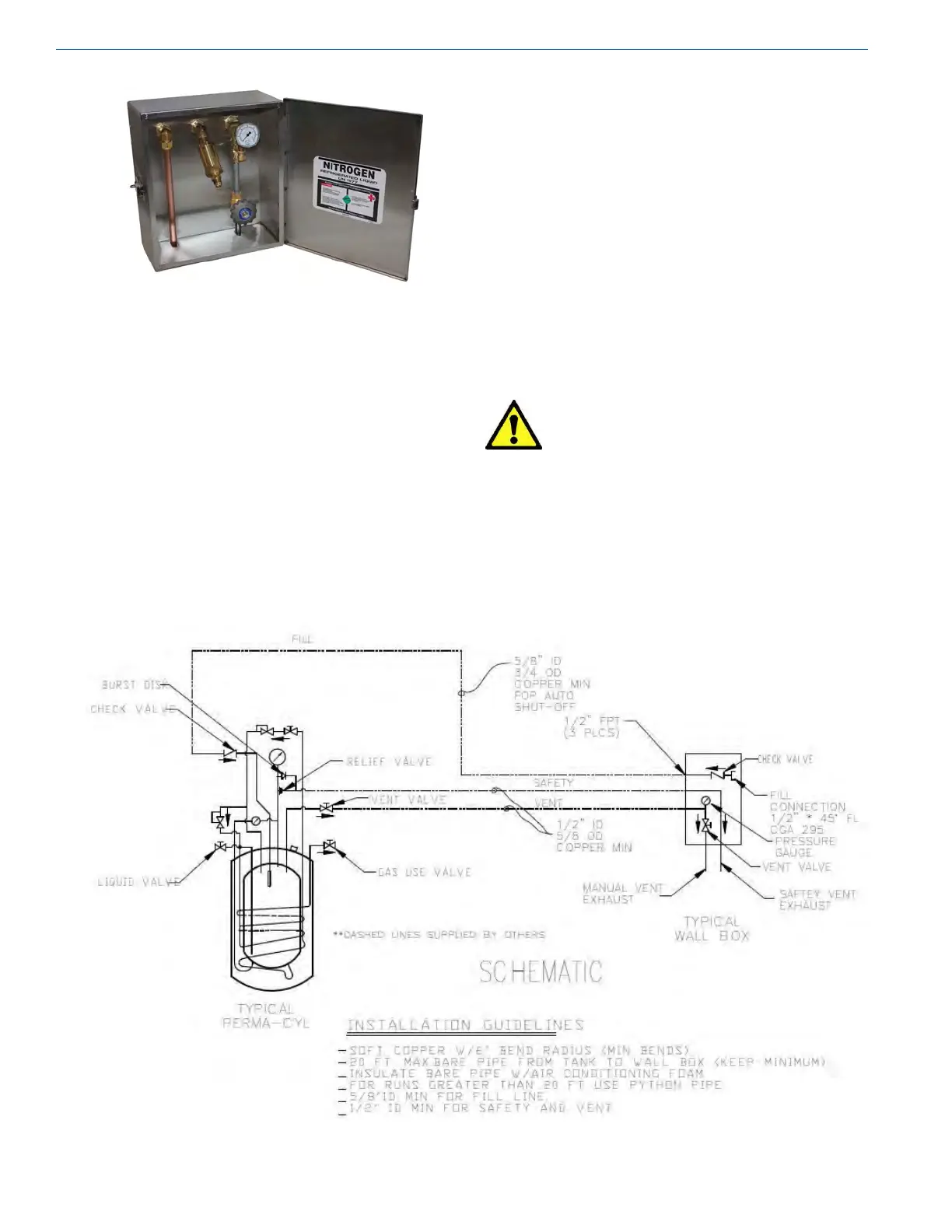

• Liquid Fill Line - The liquid ll should be piped using

a minimum diameter of 3/4” nominal copper. The

equivalent size stainless steel braided hose can also

be used. The line should be connected from the ll

connection in the wall box to the liquid ll check valve

on the Perma-Cyl System. When piping this line there are

a few guidelines that should be followed.

– Bends and elbows should be kept at a minimum.

When needed they should be made with a wide bend

radius. A minimum bend radius of 6” should be

observed.

– The length of the line from the tank to the box should

be kept to a minimum. Bare copper line can be used

for lines. If bare copper is used, it should be insulated

using air conditioning foam to keep condensation

from dripping off the piping.

– Line size should be a minimum 5/8” ID.

• Vent Line - The vent line should be run using 1/2”

nominal copper or the equivalent size stainless steel

braided hose. This line should connect the vent valve in

the wall box to the vent valve on the Perma-Cyl System.

• Relief Line - The relief line should be run using 1/2”

nominal copper. Kitec tubing or braided stainless steel

hose can also be used. Relief lines should be no smaller

in diameter than the outlet of the relief valve.

Caution! Restrictions in the relief valve

outlet piping should be avoided

to eliminate the possibility

of excessive back pressure

when the relief valve opens.

Restrictions could reduce the

required ow rate of the relief

valve and pose a potential safety

hazard.

Figure 5 - Installation Guideline Schematic

Loading...

Loading...