2

These instructions are general in nature. It is assumed

that the installer is familiar with seals and certainly with

the requirements of their plant for the successful use of

mechanical seals. If in doubt, get assistance from someone

in the plant who is familiar with seals or delay the installation

until a seal representative is available. All necessary auxiliary

arrangements for successful operation (heating, cooling,

flushing) as well as safety devices must be employed. These

decisions are to be made by the user. The decision to use this

seal or any other Chesterton seal in a particular service is the

customer’s responsibility.

Transport and store seals in their original packaging.

Mechanical seals contain components that may be subject to

alteration and ageing. It is therefore important to observe the

following conditions for storage:

• Dust free environment

• Moderately ventilated at room temperature

• Avoid exposure to direct sunlight and heat

Do not touch the mechanical seal for any reason while it is

operating. Lockout or uncouple the driver prior to personal

contact with the seal. Do not touch the mechanical seal

while it is in contact with hot or cold fluids. Ensure that all the

mechanical seal materials are compatible with the process

fluid. This will prevent possible personal injury.

• For elastomers, storage conditions should conform to

ISO 2230; particularly storage temperatures between 15°C

(59°F) and 25°C (77°F). If stored outside these ranges, the

seal assembly or spare parts should be unboxed in a clean

environment, with ambient temperature within the previously

stated ranges, and allowed to recover for at least 1 hour

prior to installation. Failure to follow this step can impact the

performance of the seal.

1.0 CAUTIONS

2.0 TRANSPORT AND STORAGE

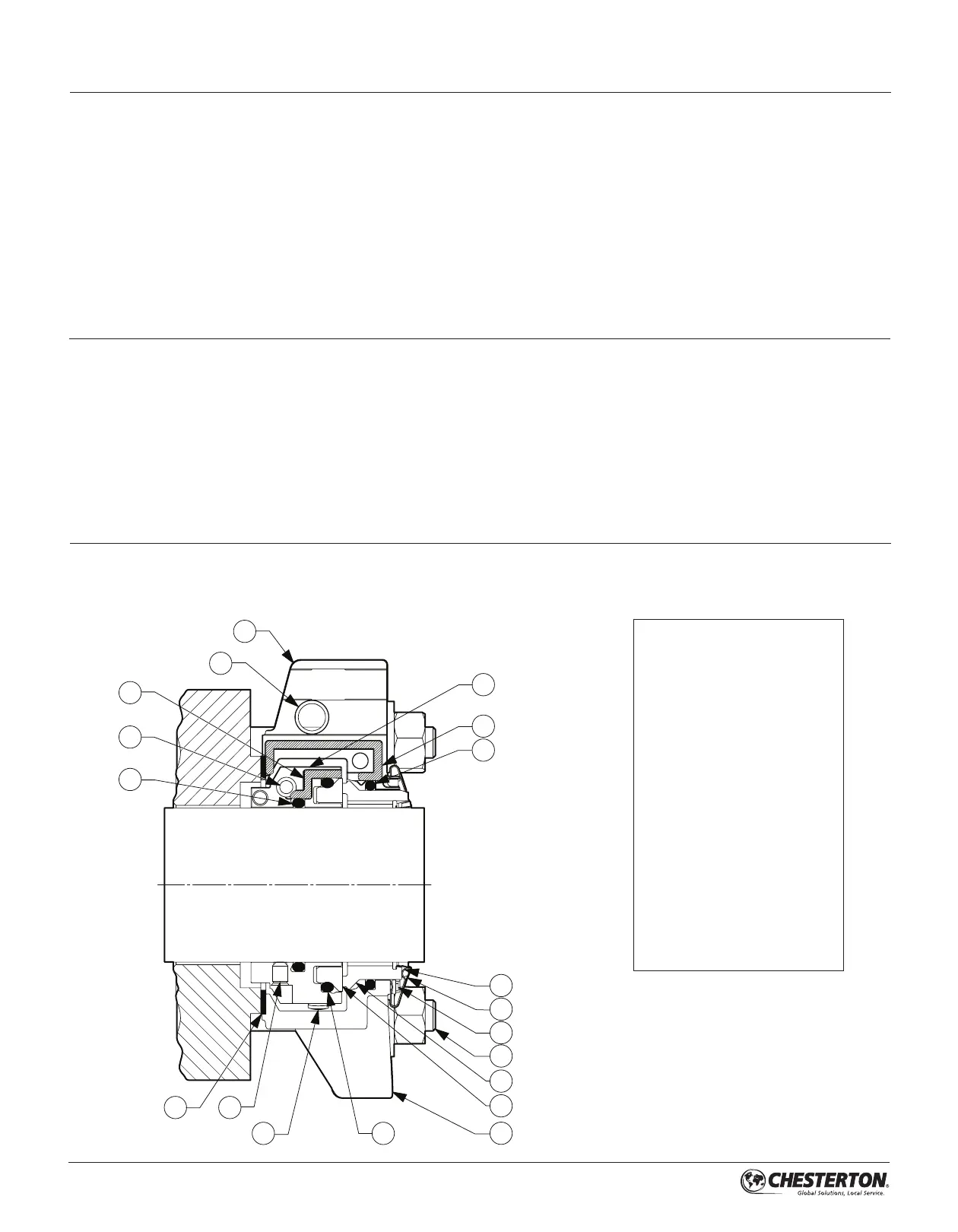

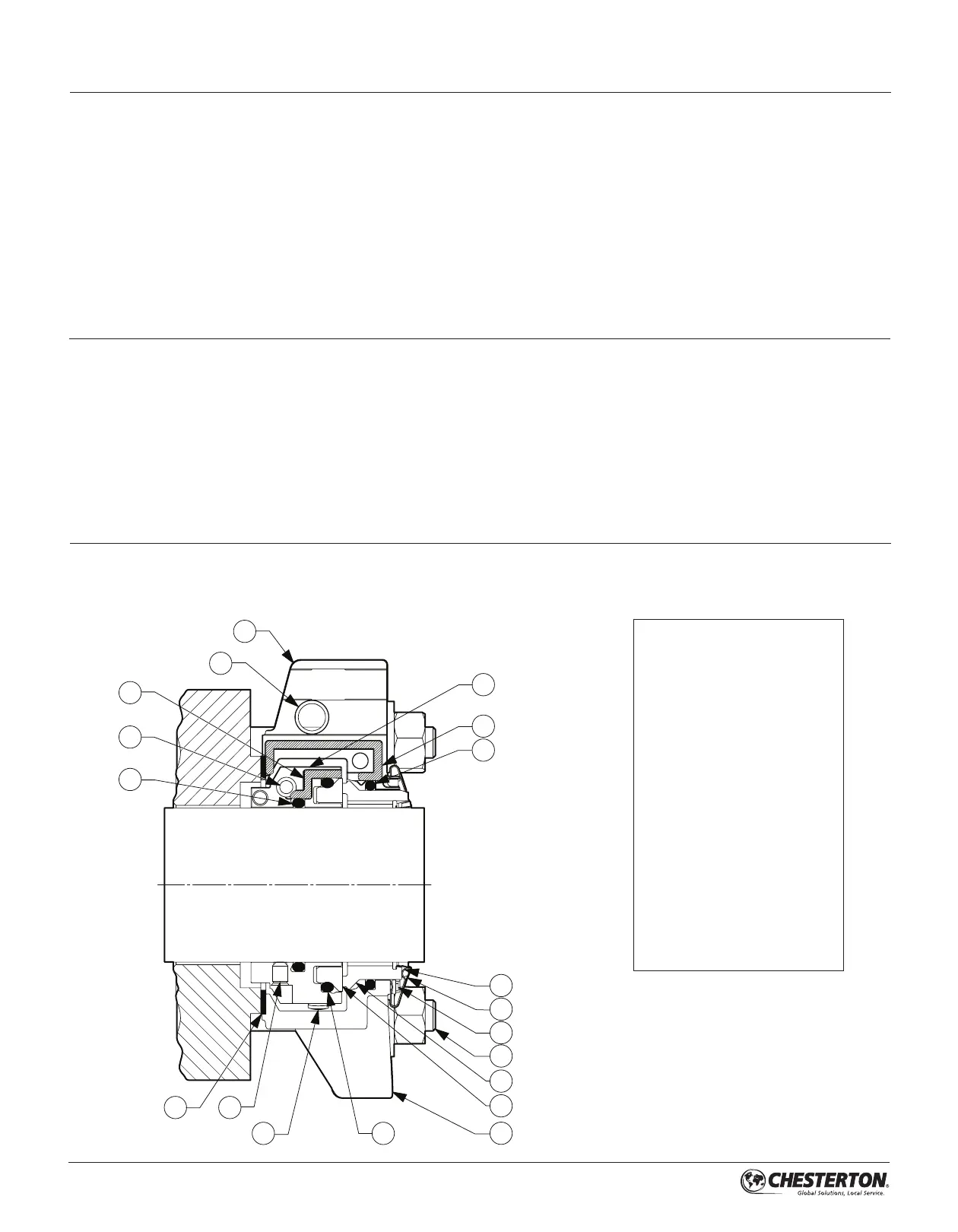

KEY

1 – Rotary Holder

2 – Holder Cap Screw (X)

3 – Holder Gasket

4 – Shaft O-Ring

5 – Rotary O-Ring

6 – Rotary Face

7 – Stationary Face

8 – Stationary O-Ring

9 – Gland Gasket

10 – Gland Cap Screw (Y)

11 – Stuffing Box Gasket

12 – Bolt Tab

13 – Spring

14 – Spring Retainer

15 – Centering Button

16 – Gland

17 – Stuffing Box Bolts (Z)

18 – Spring Lifter

19 – Holder Set Screw (W)

3.0 DESCRIPTION

3.1 Parts Identification

Figure 1

1

2

3

4

6

7

8

9

10

11

12

14

13

15

16

17

18

19

5

Loading...

Loading...