8

4.0 PREPARATION FOR INSTALLATION cont.

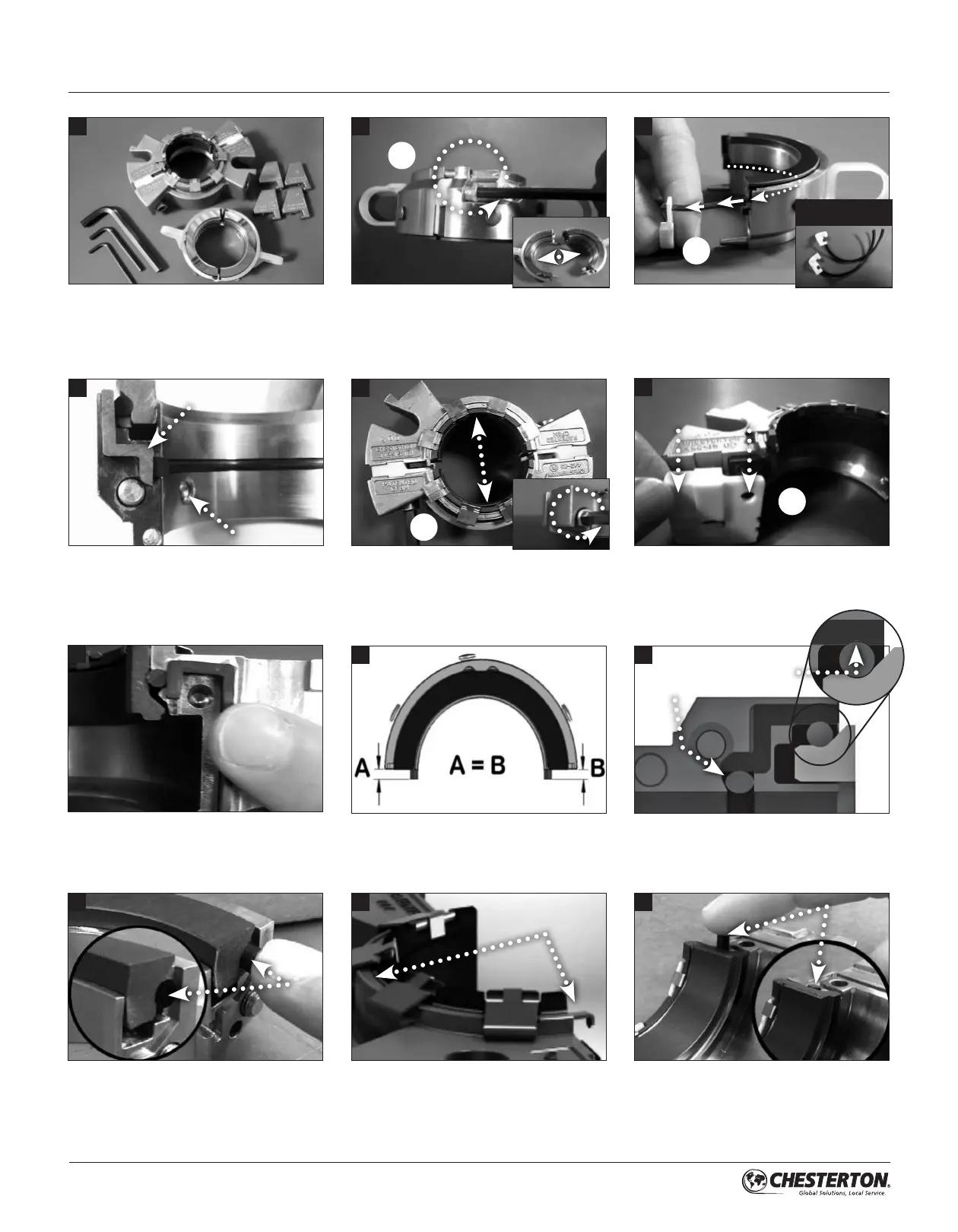

1

Remove seal from packaging and place on

clean work surface. Ensure installation spacers

are seated on outside diameter of rotary holder

halves. Important: DO NOT glue any O-Rings,

holder or gland half gaskets!

2 3

2X

2X

Disengage rotary holder screws and separate

rotary holder halves.

Important! Remove entire shipping spacer

assembly from each holder half by pulling on tab;

retain for future use. Caution: Do not push on

the rotary faces. Re-install shipping spacers if

this occurs.

Shipping Spacer

Assembly

Remove gland split shipping spacers from each

gland half.

6

2X

5

Disengage gland cap screws and separate gland

halves.

2X

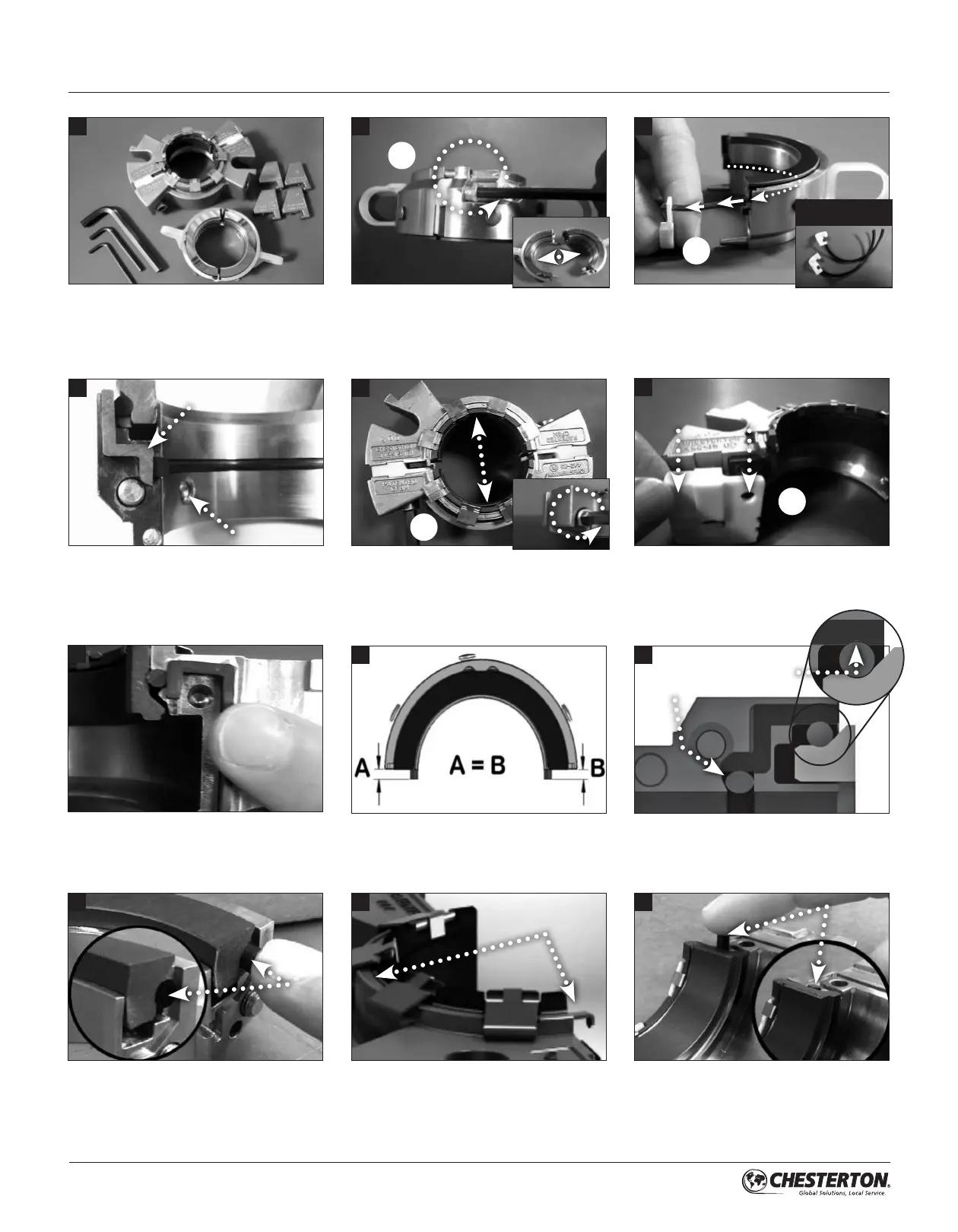

7

Ensure that the gland gaskets are lubricated and

seated in their grooves.

Ensure that the rotary holder shaft O-Ring is

properly seated in its groove with both ends

protruding evenly. Apply grease to shaft O-Ring

only where it contacts the shaft.

8

11

Ensure that gland spring lifter is extended

prior to starting installation of gland assembly.

If spring lifter is not in its proper position, review

rebuild instructions.

Spring Lifter

To prevent seal leakage, ensure that the

stationary face O-Ring ends are flush with but

not below the stationary face splits. Carefully

push on O-Ring ends if they protrude past the

face splits. Preparation complete; go to Seal

Installation

12

To prevent seal leakage, ensure that the rotary

face O-Ring ends are flush with but not below

the face splits. Push on O-Ring ends if they

protrude past the face splits.

10

9

Ensure the rotary face O-Rings are positioned

in holder O-Ring detent. If rotary face O-Rings

are not in the holder detent, review rebuild

instructions.

Rotary holder

O-Ring detent

Shaft O-Ring

4

Ensure that the holder gaskets are lubricated and

seated in their grooves. Important: Set screws

protruding past the inside diameter may cause

the holder to deform resulting in shaft leakage

and/or damage to the rotary faces.

Holder Gasket

Set Screw

Loading...

Loading...