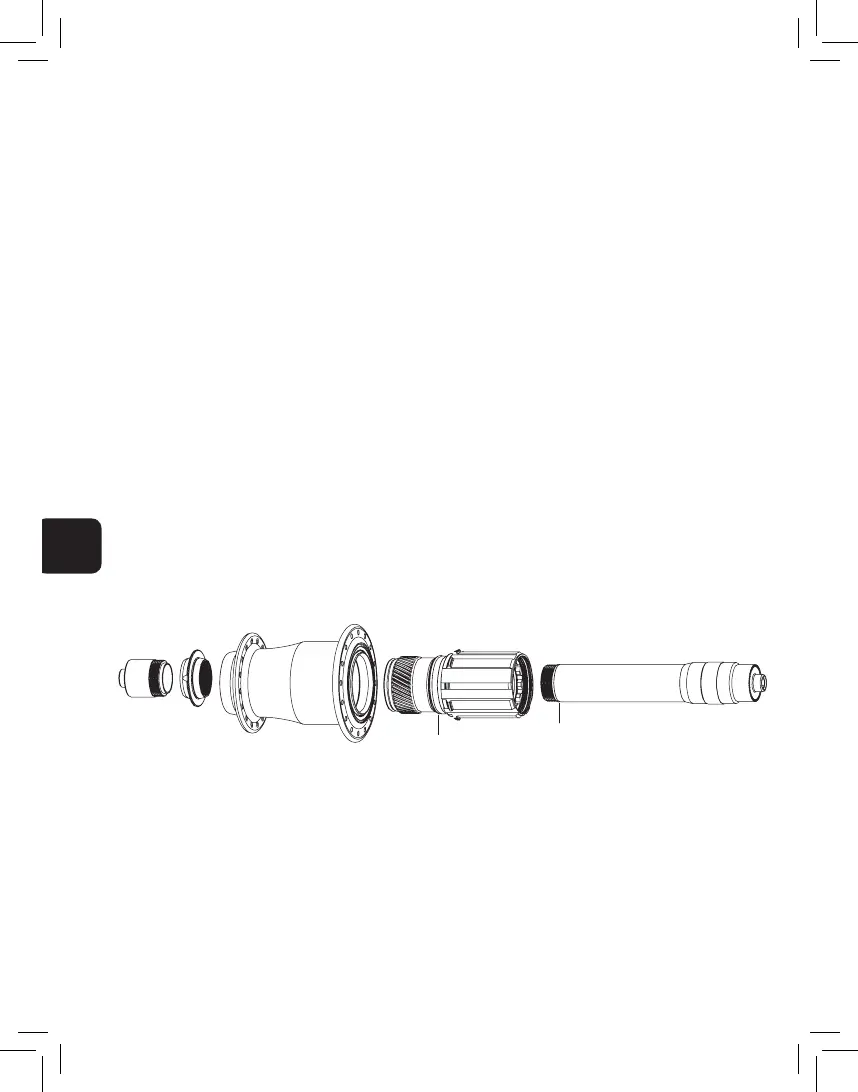

Reassembly of two piece axle on front Classic hub

(see

Figure 5)

1. Lightly grease threads on axle, adjusting cone and axle end. Apply two drops of Tri-flow

™

or a quality 10w synthetic oil to axle O-ring.

2. Insert main axle into hub shell.

3. If axle end and adjusting cone are assembled as one unit, disassemble by threading

axle end out of adjusting cone.

4. Thread adjusting cone onto the protruding threads of main axle.

5. Lightly snug adjusting cone up to bearing.

6. Thread axle end into adjusting cone until it stops.

7. Proceed to “Adjustment of two piece axle on front Classic hub”, below.

Adjustment of two piece axle on front Classic hub

(see

Figure 5)

1. Insert 5 mm hex wrenches into both ends of axle assembly.

2.

Hold right hand stationary and turn left hand counterclockwise 1/4 turn until assembly is

loose.

3. Hold hex wrenches stationary and adjust bearing preload with adjusting cone.

4. Advance adjusting cone until it just contacts bearing, then back off approximately 1/16

turn (this allows for axle compression while under skewer clamp pressure).

5. Once preload is set, tighten axle assembly to 110 inch-pounds.

6. Double check adjustment by clamping wheel into fork with quick-release. Check for

play or binding, and readjust if needed.

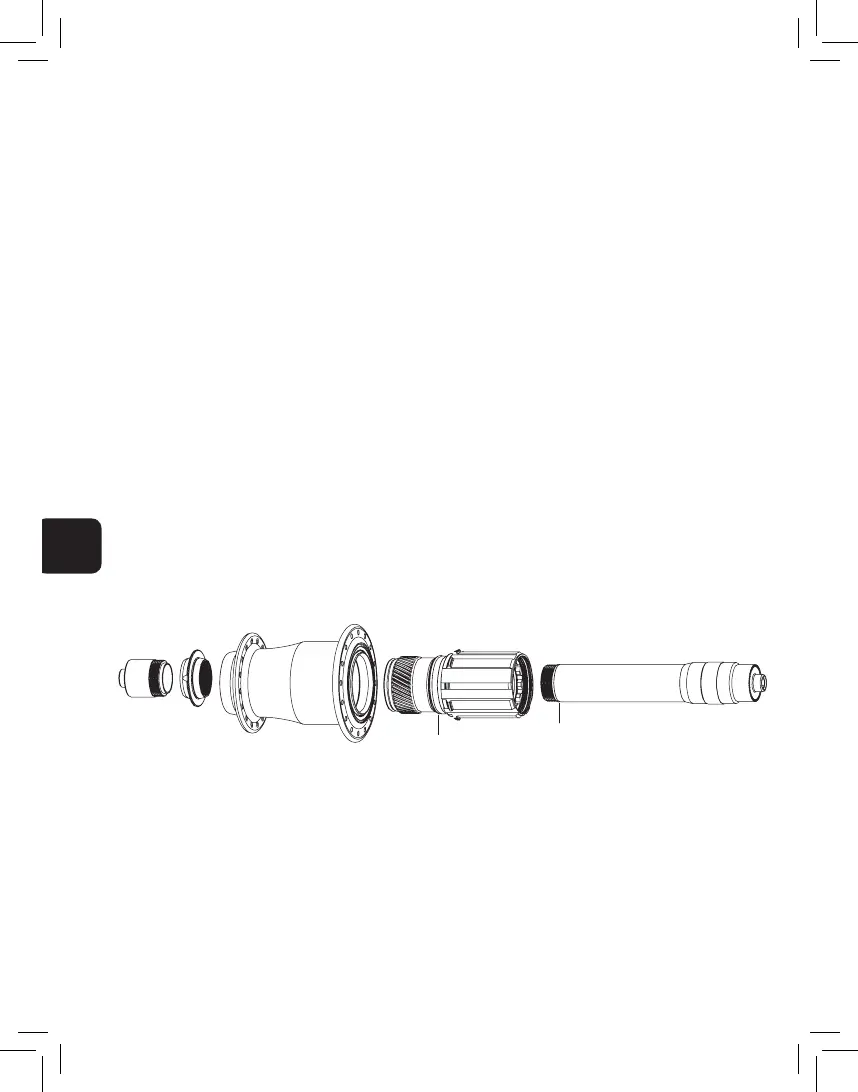

Disassembly of two piece axle on rear Classic hub

(see Figure 6)

Rear Classic

Hubshell Assembly

Driveshell

Assembly

Rear Two Piece

Axle Assembly

Figure 6

Axle End

Adjusting

Cone

O-ring

O-ring

The following instructions assume that the driveshell is facing to the right:

1.

Remove cassette lock ring and cogset using a chain whip and HG cogset lock ring removal

tool.

2. Insert 5 mm hex wrenches into both ends of axle assembly.

3. Hold right hand stationary and turn left hand counterclockwise 1/4 turn until assembly is

loose.

4. Loosen and unscrew adjusting cone and axle end until they are free from the main

axle.

5. Remove axle by pulling on drive side end of axle.

6. Hold hub or wheel in one hand and pull driveshell out with the other.

7.

Hub shell bearings, RingDrive engagement and driveshell bearing assemblies can now be

accessed.

For RingDrive inspection and maintenance information, see “The RingDrive”, pg. 11.

For

bearing service information see “Service of the bearings”, pg. 13.

Further disassembly requires specialized tools. These come individually or in the Chris King

Hub Service Tool Kit, which is available at any authorized Chris King dealer, or directly from

Chris King Precision Components.

Reassembly of two piece axle on rear Classic hub

(see Figure 6)

The following instructions assume that the driveshell is facing to the right:

1. Lightly grease threads on axle, adjusting cone and axle end. Apply two drops of Tri-flow™

or a quality 10w synthetic oil to O-ring on axle and driveshell.

2. Insert driveshell into the hub shell; turn in a clockwise motion while letting it pull itself

in. A distinctive click sound will indicate that the driveshell is firmly seated.

3. Insert main axle through driveshell. The axle is properly seated when the threaded end

appears through the bearing and the end is flush with the end of the hub shell.

4. If axle end and adjusting cone are assembled as one unit, disassemble by threading

axle end out of adjusting cone.

5. Thread adjusting cone onto the protruding threads of main axle.

6. Thread axle end into adjusting cone until it stops.

7. Proceed to “Adjustment of two piece axle on rear Classic hub”, below.

Note: To improve performance, the axles have been precisely matched with the needle bearings

in the driveshell. Be sure to combine only like numbered parts, (e.g., #3 axle with #3 needle

bearing race).

Adjustment of two piece axle on rear Classic hub

(see Figure 6)

The following instructions assume that the driveshell is facing to the right:

1. Insert 5 mm hex wrenches into both ends of the axle assembly.

2.

Hold right hand stationary and turn left hand counterclockwise 1/4 turn until the assembly is

loose.

3. Hold hex wrenches stationary and adjust bearing preload with the adjusting cone. You

may use the hub cone adjusting tool if necessary.

4. Advance adjusting cone until it contacts bearing. The rear hub takes a slightly higher

amount of preload than “no play”, since some settling may occur while riding.

5. Once preload is set, tighten axle end to 110 inch-pounds.

6. Check adjustment by clamping wheel into frame with quick-release. Ride for 5-10

minutes, check for play or binding, and readjust as necessary. Double check adjustment

after the first 5-10 miles of riding.

Note: Correct adjustment of the rear hub is necessary for proper engagement of the RingDrive.

If the hub is run loose, the RingDrive may not engage properly and could lead to permanent

damage of the internal parts.

6

Loading...

Loading...