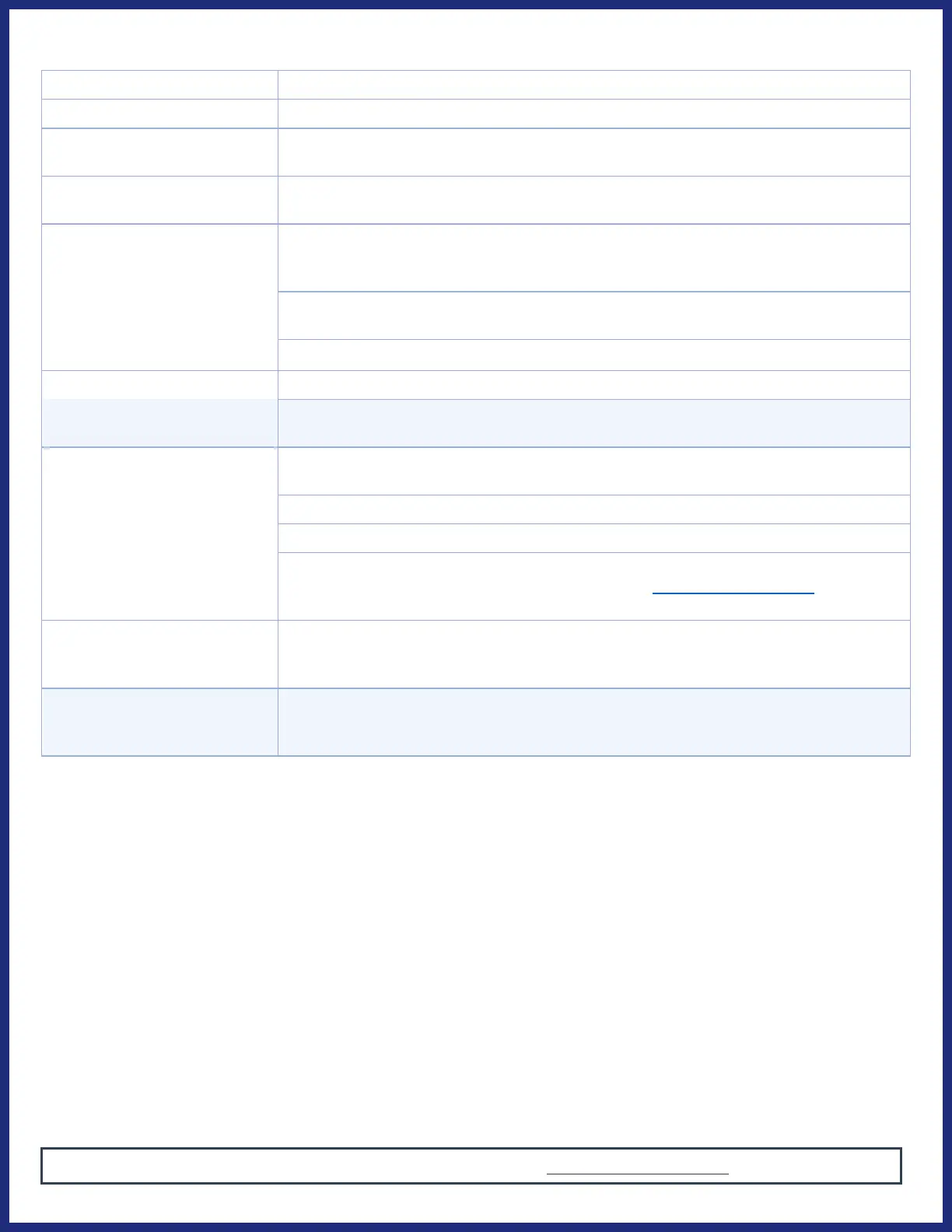

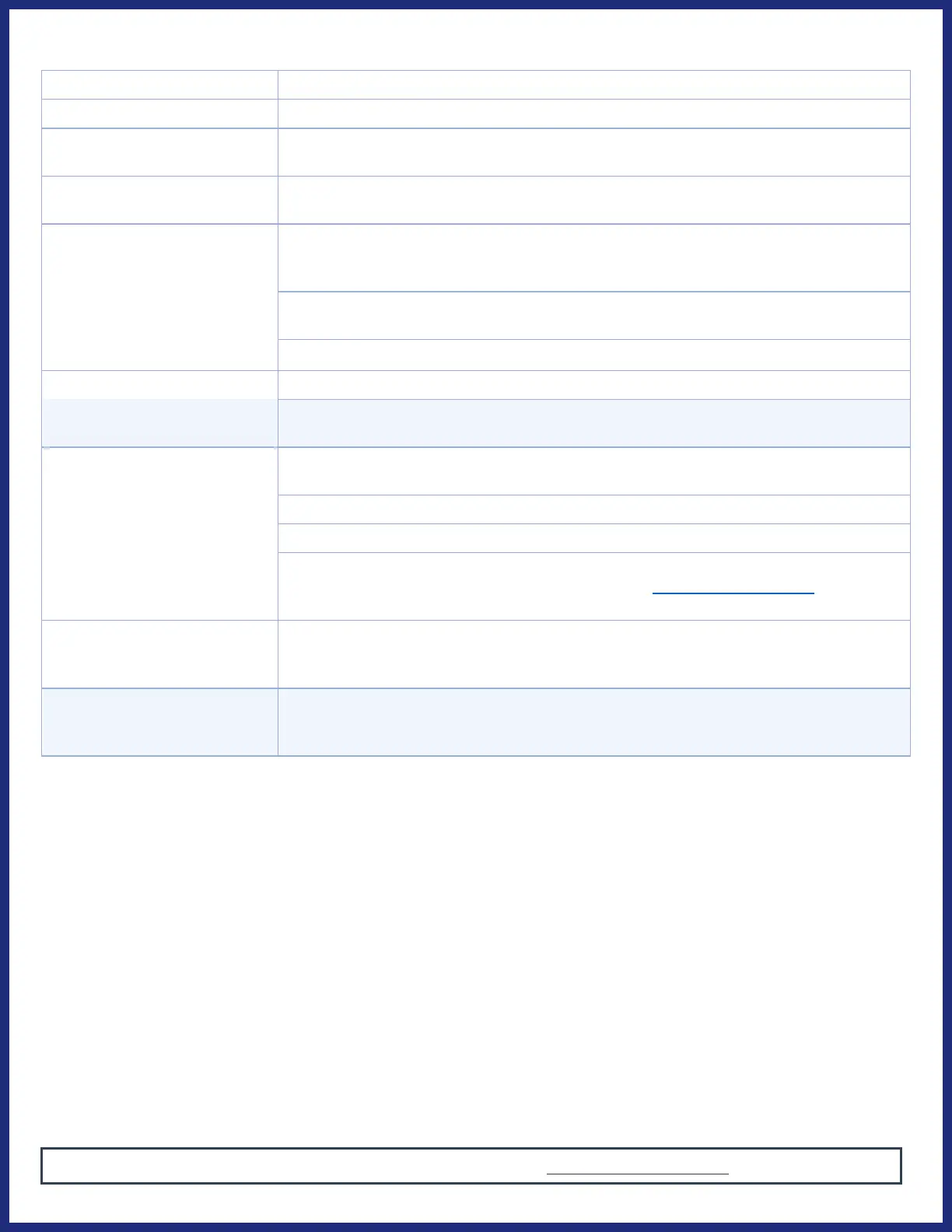

Verify that pump is set to run with salt system.

Flow Sensor is not connected to Controls

Flow Sensor is not facing correct direction

Ensure red arrow on Flow Sensor points with the

correct direction of water flow in return plumbing

Ensure that there is not a pocket of air in the Cell

or Flow Sensor

Set variable speed pump RPM’s higher in order

trigger Flow Sensor and keep the Cell completely

filled with water.

Verify correct orientation, cable is plugged in, 6-

12" of straight pipe before Flow Switch

Ensure O-Rings are clean and in good condition.

Threaded collars are cross-threaded or

pipes are misaligned

Inspect threads for damage, ensure that each

screws back on without resistance.

Ongoing typical issue, see previous sections

Verify 3500ppm salt, clean cell, no air in cell during

operation, no debris or damage in cell.

Have professional check wiring.

Loose, dirty, or damaged system cables

Check system’s connectors are properly seated

Check dedicated Troubleshooting Guide for EDGE

models at www.circupool.com/help, see chapter

“How to Diagnose System Error Codes”

Cell frequently has mineral

buildup

This is due to imbalanced water chemistry

and a high Saturation Index

Ensure that your Saturation Index is at or near

zero, in order to avoid damage or premature Cell

failure. (page 8)

Cell never or rarely has mineral

buildup

Water may be corrosive due to imbalanced

water chemistry and a low Saturation Index

Ensure that your Saturation Index is at or near

zero, in order to avoid damage or premature Cell

failure. (page 8)

For more information or troubleshooting, visit www. circupool.com/help

Loading...

Loading...