3-6

Catalyst 6500 Series Supervisor Engine Guide

OL-7397-03

Chapter 3 Installing Supervisor Engines

Installing a Supervisor Engine

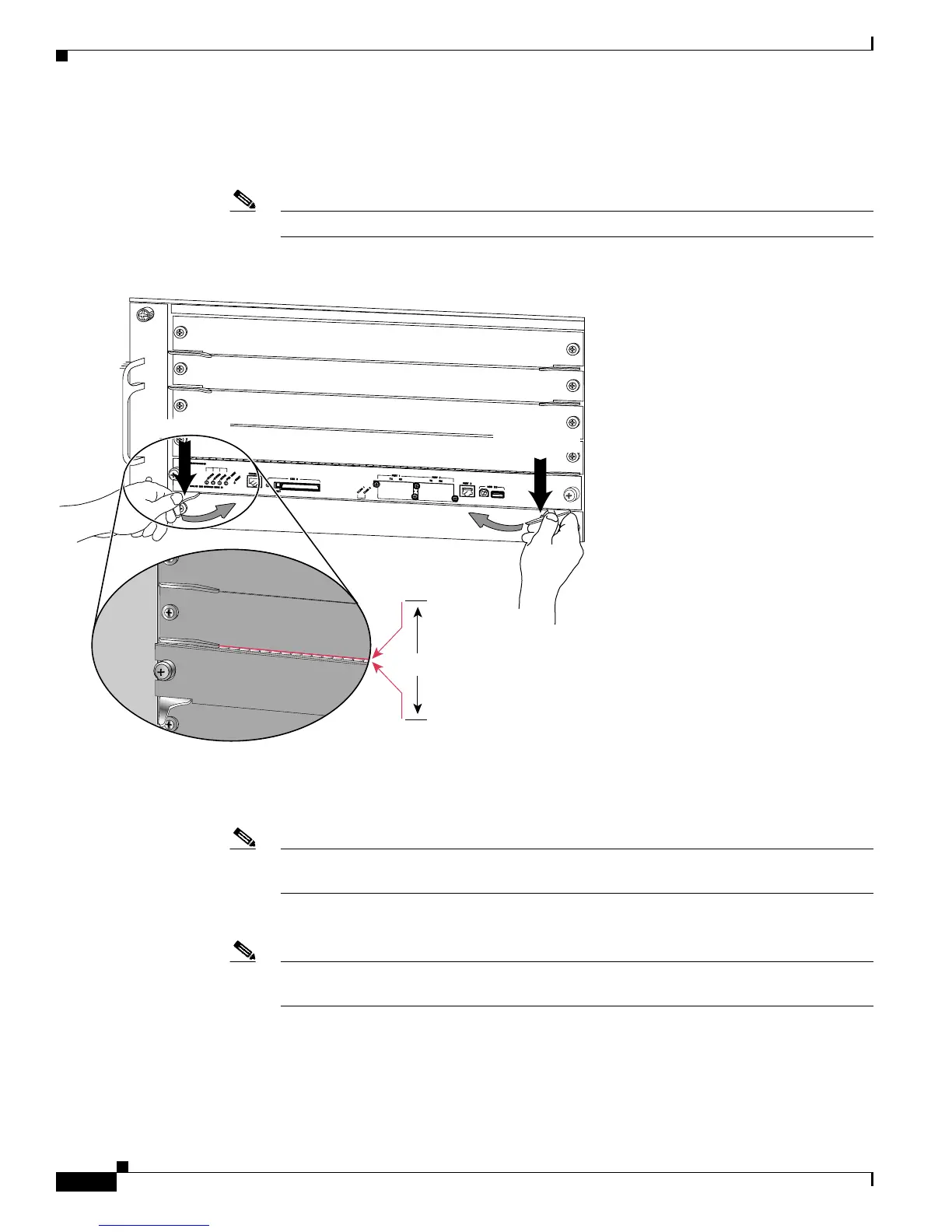

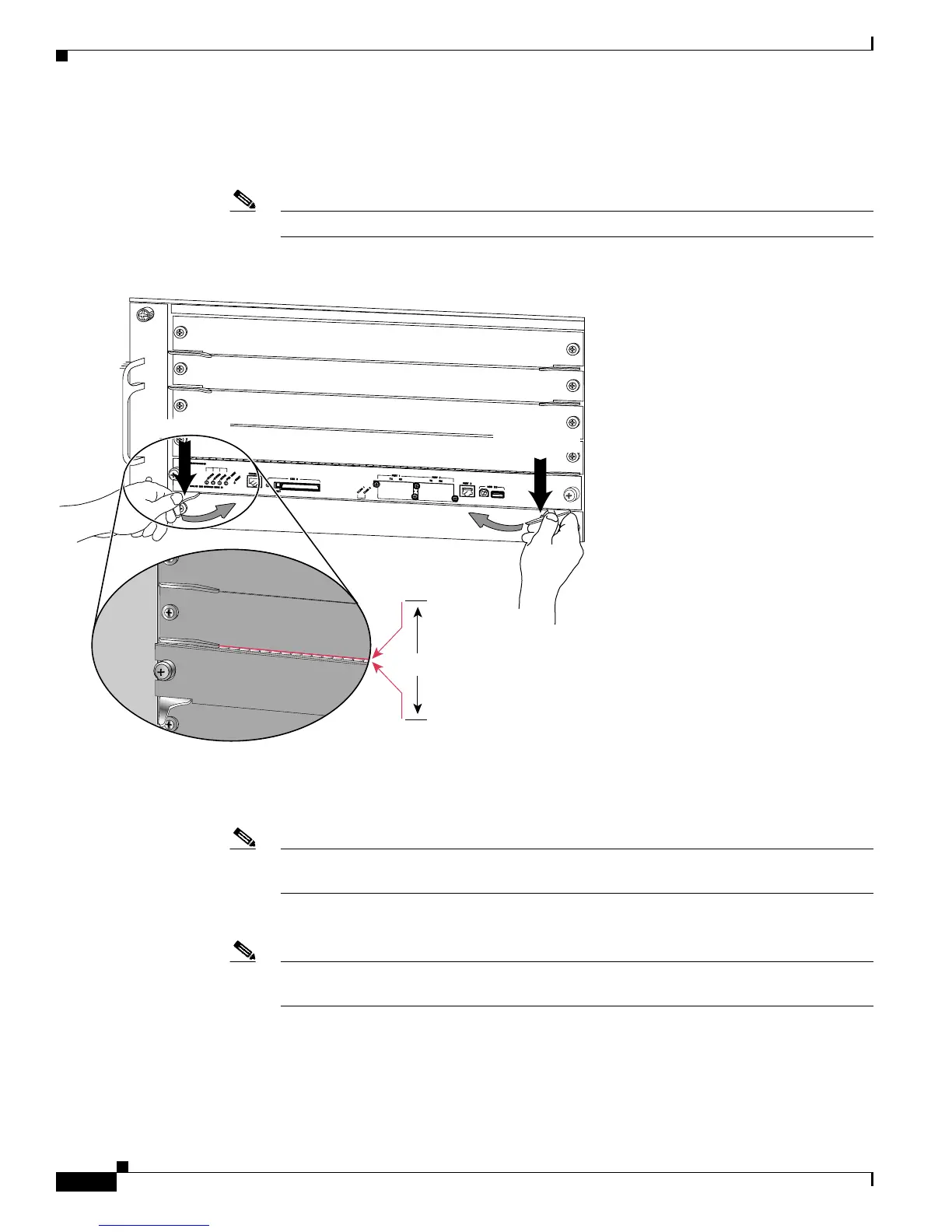

c. Using the thumb and forefinger of each hand, grasp the two ejector levers and gently press down to

create a small 0.040

inch (1 mm) gap between the supervisor engine’s EMI gasket and the module

or cover plate above it. (See

Figure 3-2.)

Note Do not press down too forcefully on the levers because they will bend and get damaged.

Figure 3-2 Clearing the EMI Gasket in a Horizontal Slot Chassis

d. While gently pressing down, simultaneously close the left and right ejector levers to fully seat the

supervisor engine in the backplane connector. The ejector levers are fully closed when they are flush

with the supervisor engine faceplate.

Note Failure to fully seat the supervisor engine in the backplane connector can result in error

messages.

e. Tighten the two captive installation screws on the supervisor engine.

Note Make sure the ejector levers are fully closed before tightening the captive installation

screws.

f. Verify that the supervisor engine STATUS LED is lit.

1

2

3

FAN

STATUS

4

5

6

1mm

1

2

Gap between the module

EMI gasket and the

module above it

Press down

Press down

130909

Loading...

Loading...