PF-F/PFU Series

Model No.

Dimension D

PF8000F 40 mm

PF16000F 50 mm

Mounting, installation and adjustment

■

Do not use a load that can produce surge voltage. When

directly running the load that generates a surge such as

relay and solenoid valve, use a surge absorbing element

built-in. If there is a surge source on the same power

supply line, similarly implement surge protection.

■

This product has no protection against lightning surge.

This product is CE marking compliant but has no protection

against lightning surge. For the protection against lightning

surge, take countermeasures on the equipment side

.

■

Make sure that the lead wire is free of repeated

bends and tension. This may lead to disconnection.

■

Use the accessory cable (3 m). When extending the

cable, contact your CKD branch or dealer.

■

When connecting pipes, wrap sealing tape in the

opposite direction from the threading, from the

inside position to within 2 mm from the pipe end.

●

If sealing tape protrudes from the pipe threads, it could be

cut when screwing the bolts in. This could cause the tape

to enter the product, causing failures.

●

When using a liquid sealant, make sure it does not

adhere to resin parts. Otherwise resin parts could be

damaged, which is dangerous.

■

Check that the piping connected to the pneumatic

components is not dislocated due to vibration,

looseness, or tension.

●

Piping dislocation is dangerous.

■

Observe the following precautions when using

nylon tubes or urethane tubes for piping material.

●

Use ame-resistant tubes or metal steel pipes in an

environment where spattering may occur.

●

When using the standard push-in tting on the spiral tube,

x the base of the tube with a hose clamp. Rotation may

occur, causing a reduction in holding force.

■

Connect piping so that connections are not

dislocated by equipment movement, vibration, or

tension.

■

Always ush just before piping pneumatic components.

●

Any foreign matter that has entered the pipes during

piping must not enter the pneumatic components.

■

Use appropriate torque to tighten the pipes when

connecting them.

●

The purpose is to prevent air leakage and damage to bolts.

●

First tighten the bolts by hand to ensure that the threads

are not damaged, then use a tool.

■

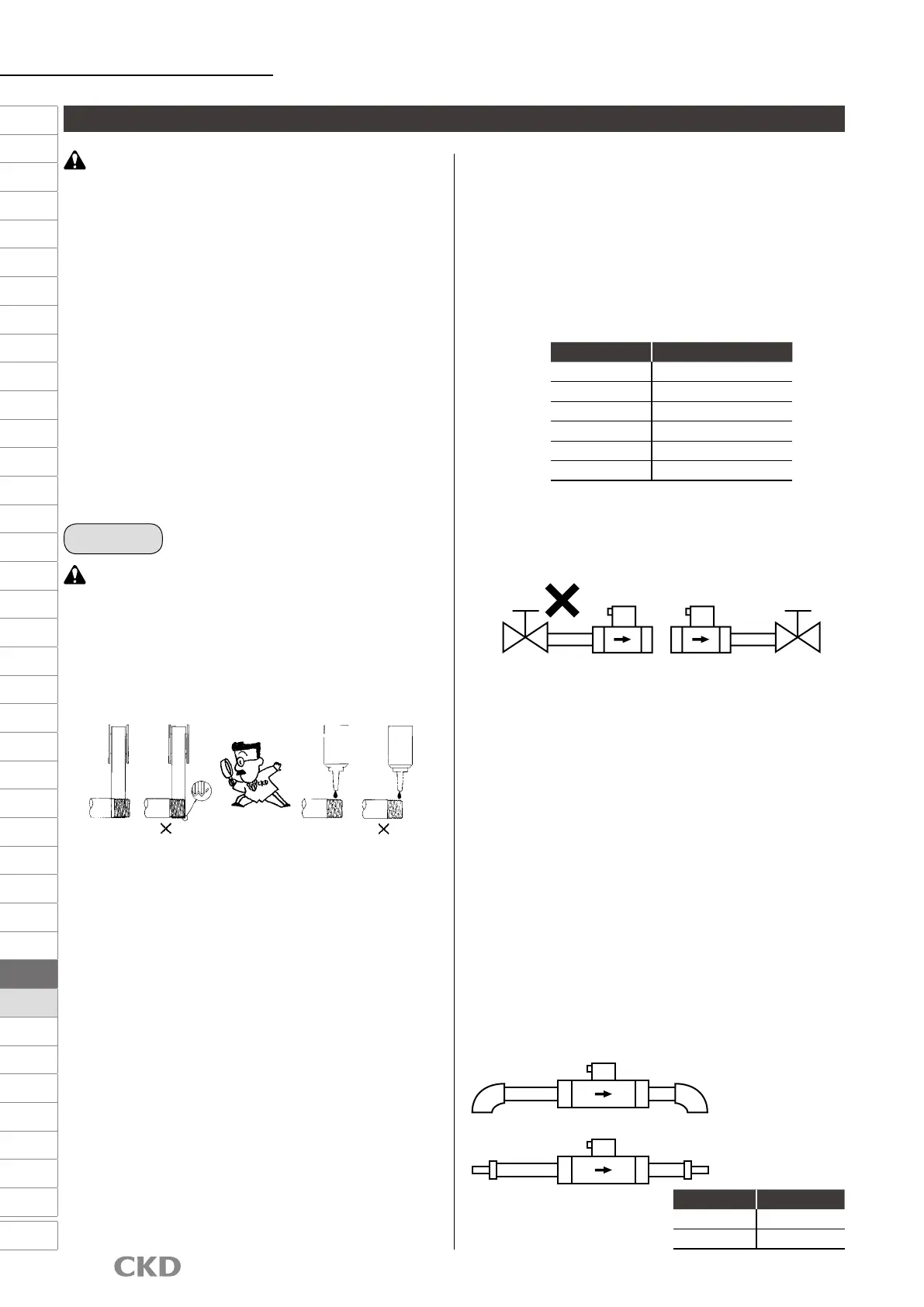

When adjusting the ow rate using a metering valve (glove

valve, ball valve, etc.), install the metering valve on the

secondary side (downstream side) of the sensor.

Generated drift (turbulence in the ow) could cause errors

.

■

Do not install the regulator immediately before the

sensor. Generated drift may cause errors.

●

When installing the regulator on the primary side, provide

a straight piping section of 10D and over.

* Where "D" indicates the inner diameter of the piping

material.

●

Select a regulator that has sufcient margin of ow

characteristics for the max. ow rate of the sensor.

■

Align the uid ow direction to the direction indicated

on the sensor when connecting the pipes. When

connecting it in reverse, the larger value is displayed.

■

When using an elbow or bush in the piping, it is

recommended to provide straight piping sections of

10D and over on the primary side and 5D and over

on the secondary side.

●

For PF8000F/PF16000F Series, be sure to provide

straight piping sections.

●

Bore size change by bush should be limited to one size.

3. Piping

CAUTION

CAUTION

[Recommended values]

Port thread

Tightening torque N·m

Rc3/8 22 to 24

Rc1/2 28 to 30

Rc3/4 31 to 33

Rc1 36 to 38

Rc1 1/2 48 to 50

Rc2 54 to 56

Solid

liquid

sealant

Solid

liquid

sealant

OK OK

OK

When using bush tting

5D

10D

When using elbow tting

5D

10D

F.R.L

F (Filtr)

R (Reg)

L (Lub)

PresSW

Shutoff

SlowStart

FlmResistFR

Oil-ProhR

MedPresFR

No Cu/

PTFE FRL

Outdrs FR

F.R.L

(Related)

CompFRL

LgFRL

PrecsR

VacF/R

Clean FR

ElecPneuR

AirBoost

SpdContr

Silncr

CheckV/

other

Jnt/tube

AirUnt

PrecsCompn

Mech/

ElecPresSw

ContactSW

AirSens

PresSW

Cool

AirFloSens/

Contr

WaterRtSens

TotAirSys

(Total Air)

TotAirSys

(Gamma)

RefrDry

DesicDry

HiPolymDry

MainFiltr

Dischrg

etc

Ending

1390

Loading...

Loading...