Operating Hazards

A

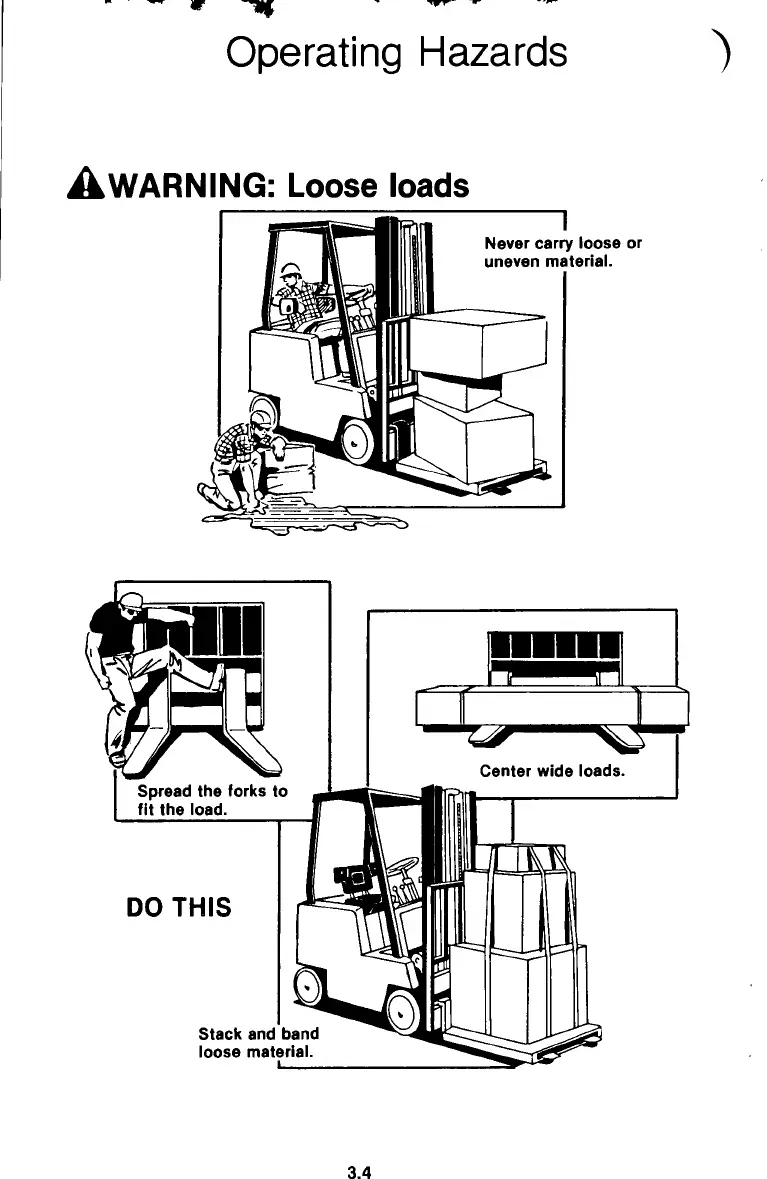

WARNING:

Loose

loads

Never

carry

loose

or

uneven material.

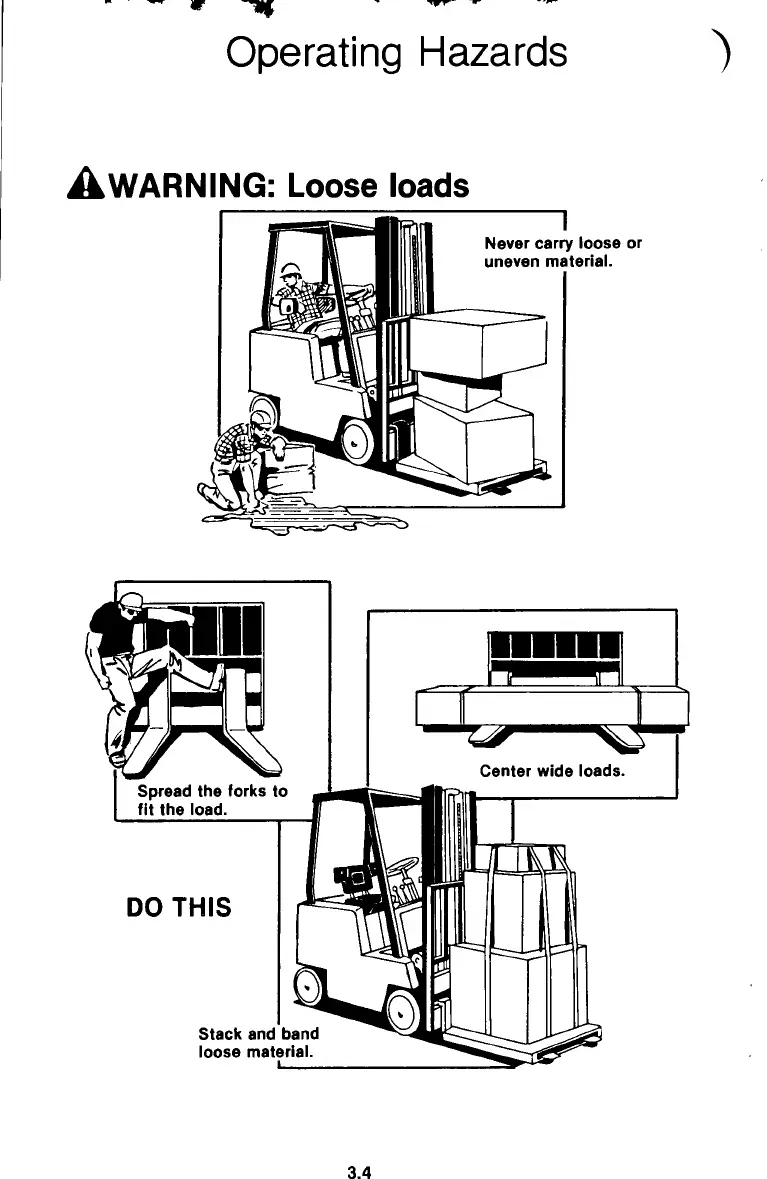

Spread

the

forks

to

fit

the

load.

DO

THIS

Stack

and

band

loose material.

3.4

•r

**

•}

t

Planned

Maintenance

and

Lubrication

Recommended

Planned

Maintenance

Intervals

Operating

conditions

Time intervals between maintenances

are

largely determined

by

operating

conditions.

For

example, operation

in

sandy, dusty locations requires shorter

maintenance intervals than operation

in

clean warehouses.

The

indicated

in-

tervals

are

intended

for

normal opera-

tion.

To

allow better understanding

of

this aspect,

the

following clarification

should

be

made:

NORMAL

OPERATION:

Basically, eight-hour material handling,

mostly

in

buildings

or in the

open air.

SEVERE

OPERATION:

Prolonged operating hours

or

constant

usage.

EXTREME

OPERATION:

1.

In

sandy

or

dusty locations, i.e.

ce-

ment plant, lumber

or

flour

mills,

coal dust

or

stone crushing sites.

2.

High-temperature locations, i.e.

steel mills, foundries, etc.

3.

Sudden temperature changes (con-

stant trips from buildings into

the

open

air), e.g. refrigeration plant.

If

your

fork-lift

truck

is

used

in

extreme

operating

conditions,

you

must

shorten

the

maintenance intervals

ac-

cordingly.

Ensure

operational

safety

8.3

Loading...

Loading...