ADJUSTMENTS

AND

TESTING

SIMPLA 50B-BT

SIMPLA 55BT

SIMPLA 65BT

SIMPLA 50BST

Doc. 10021896

Issued 09/2010

Ver. AB

Page 10 of 16

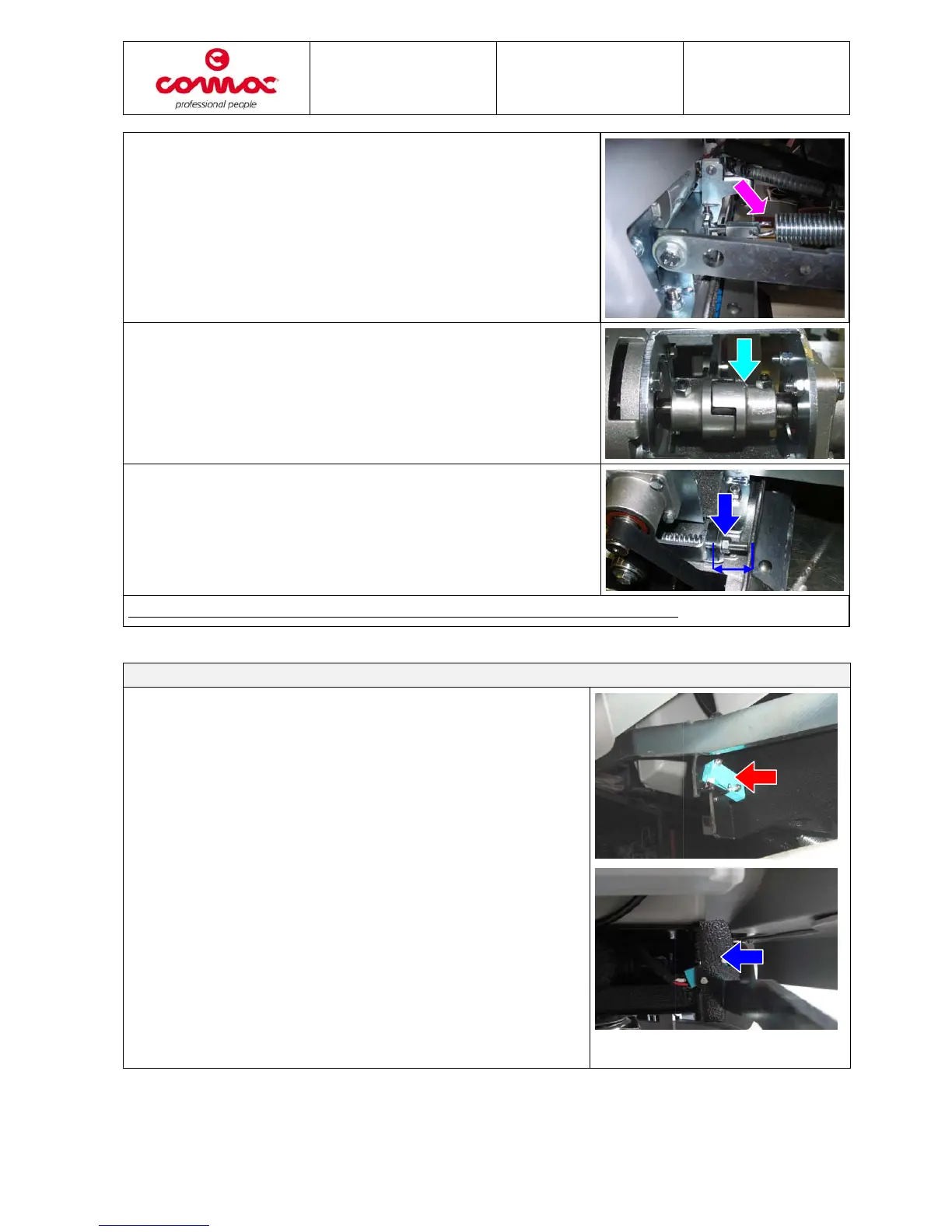

4. Adjust the pressure relief spring by tightening the M6 screw

on the tie rod until 5-6 mm of thread remain, so as to obtain

the correct pressure on the base.

5. Assemble the transmission coupling so that there are 2 mm.

between the two hubs and that the rubber toothed star

situated between the two works properly, no vibrations or

misalignments.

6. Tighten the dowels and related nuts.

7. Adjust the drive belt tension by means of the

M8 nut, so that the thread protrudes from the support by

approx. 28-29 mm.

Refer to the WASHING version for the adjust of the automatic version.

Adjusting the Washing Base (50 B-BT)

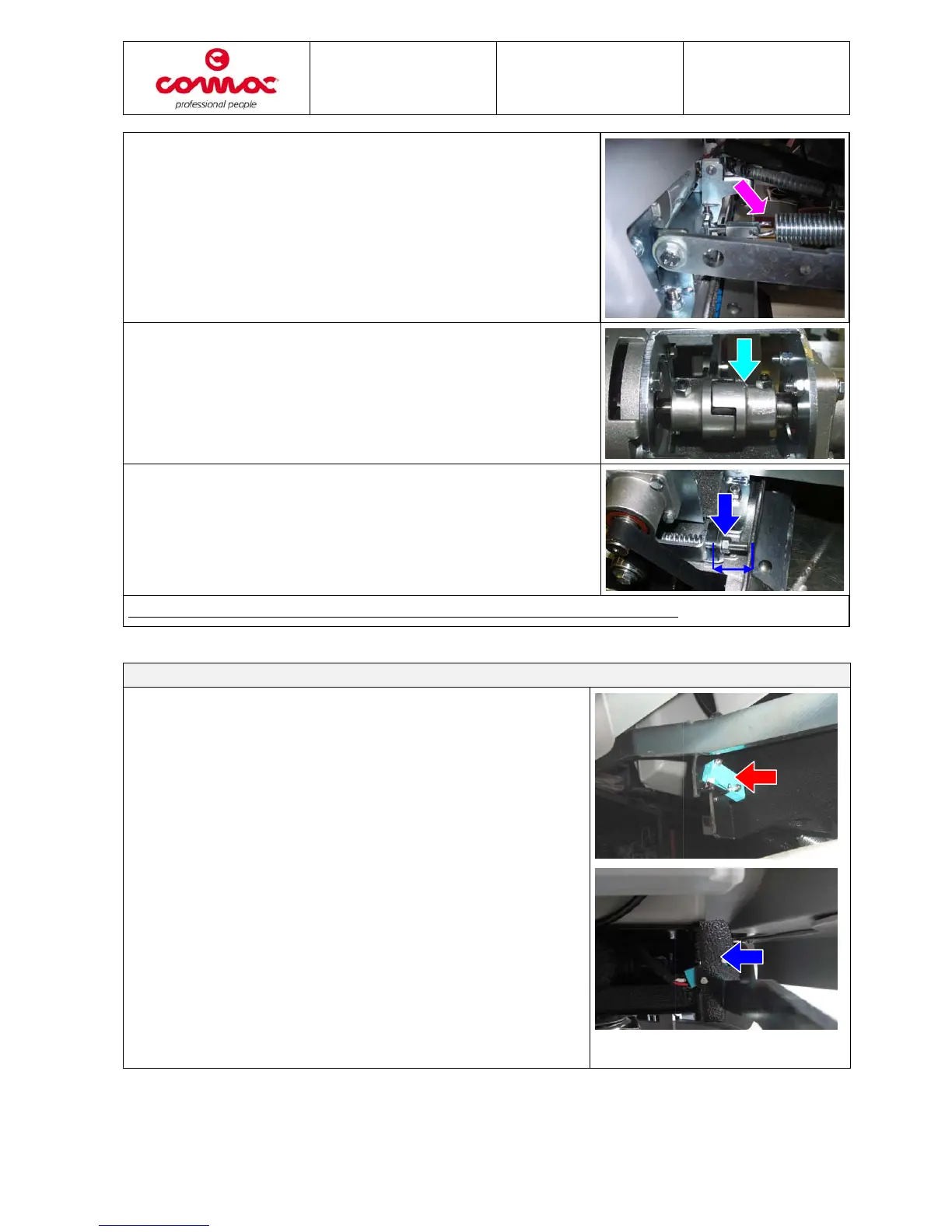

1. With the pedal fixed in place, check the base confirmation

microswitch changes over and the roller remains about

0.5mm from the main body of the switch.

2. If necessary, adjust the microswitch as follows:

• loosen the M3 locknut and the relative M3 screw;

• move the microswitch in its slot;

• fix the M3 locknut and relative M3 screw until the

microswitch is blocked, taking care not to over-tighten

(and therefore damage the device itself);

• after adjusting, check the microswitch is functioning

correctly and, if necessary, repeat the calibration.

3. Carry out a functional test to check that, with the base

down, the brushes begin turning when the machine is set for

working operation.

Loading...

Loading...