INSTRUCTIONS FOR TECHNICAL PERSONNEL

43

INSTALLATION

During installation, carry out proper machine levelling, which is a prerequisite

for a correct operation thereof (max. tolerance 2°).

In order to prevent any damage caused by steam going out of the machine,

make sure that the surrounding materials do not deteriorate in its presence.

After machine installation check thermostat settings, booster 85°C, tank 60°C.

1)ELECTRICAL CONNECTION

The electrical safety of this equipment is only assured if it is connected as

follows.

It is necessary to connect the equipment to an effective earthing as specified

by the electrical safety regulations in force. Check that this basic requirement

is complied with, in case of any doubt ask for a careful check of the

installation by a qualified personnel.

In the case the earthing is not efficient there will be a dispersion due to the

suppresser.

The machine shall be included in a correctly dimensioned equipotential, whose

effectiveness is to be very tight in accordance to the procedures set for in the

applicable safety standards. The connection shall be performed through a

screw marked by a plate ( ) near the rear side of the appliance.

The manufacturer declines any responsibility for any damages caused by lack

of an effective ground installation. For the electrical power supply have

available a wall circuit breaker switch with multiple phase protection

according the following table with contact aperture distance, equal to or not

exceeding 3mm and a supply cable no less than 2.5mm².

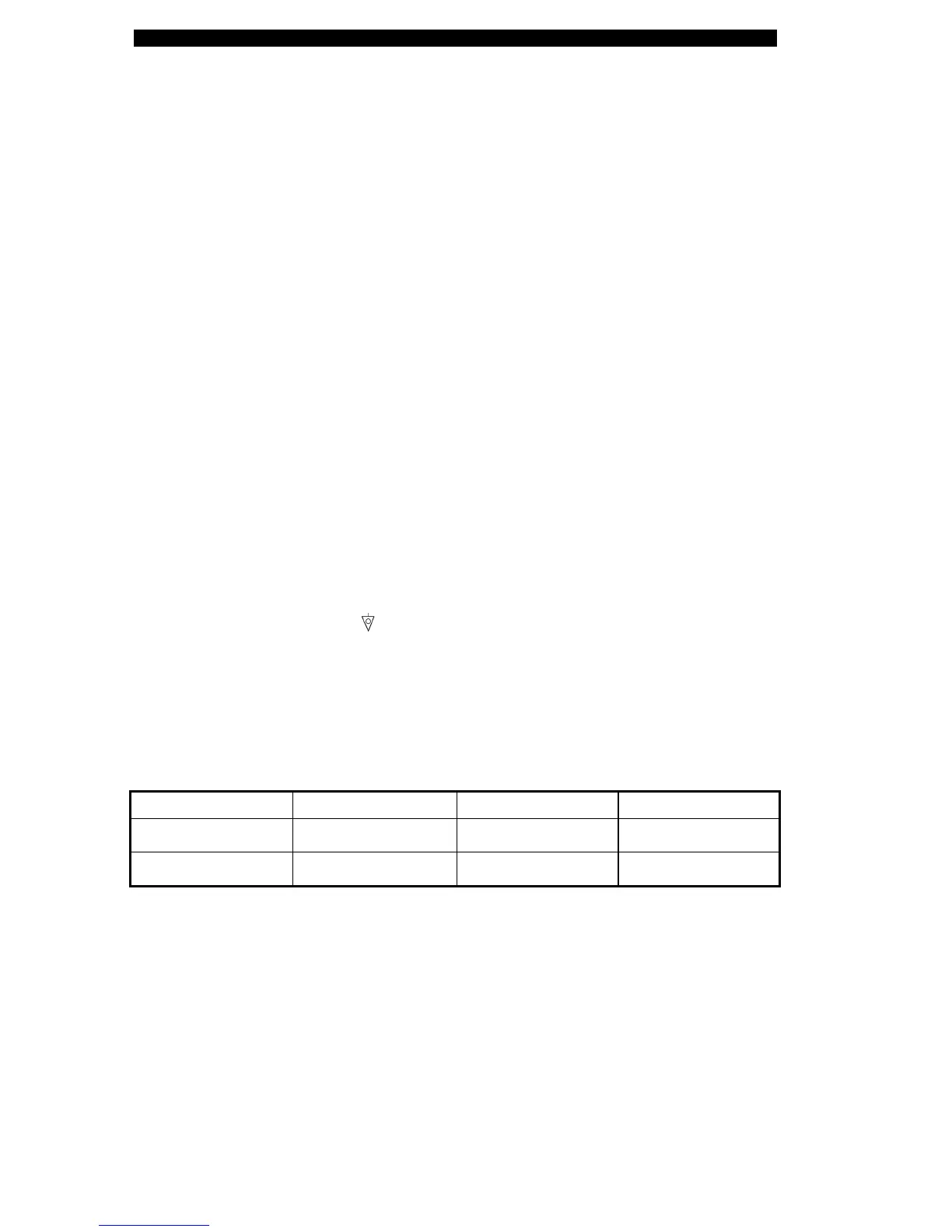

model Supply 380V 3N Supply 220V/3 Supply 220V/1

LP360 16A 16A 32A

LC380 20A 32A 63A

For other supplies the cable cross section and the circuit breaker switch must

be calculated according to voltage and length of cabling. If cabling too long

adjust cable size to Amp rating; do not pull on supply cable or install it under

tension. If cable needs to be replaced use type H07RN-F.

Loading...

Loading...