6

D S - 9 . 5 i

B A T T E R Y

B L A C K ( - )

R E D ( + )

C I R C U I T B R E A K E R ( O P T I O N )

114.3 mm

(4 1/2")

B A T T E R Y

A

F 1

F 2

B L A C K

R E D

B L A C K ( - )

R E D ( + )

C I R C U I T B R E A K E R ( O P T I O N )

S O L E N O I D S

R E M O T E

S W I T C H S O C K E T

W I N C H

Ⅲ

ⅢⅢ

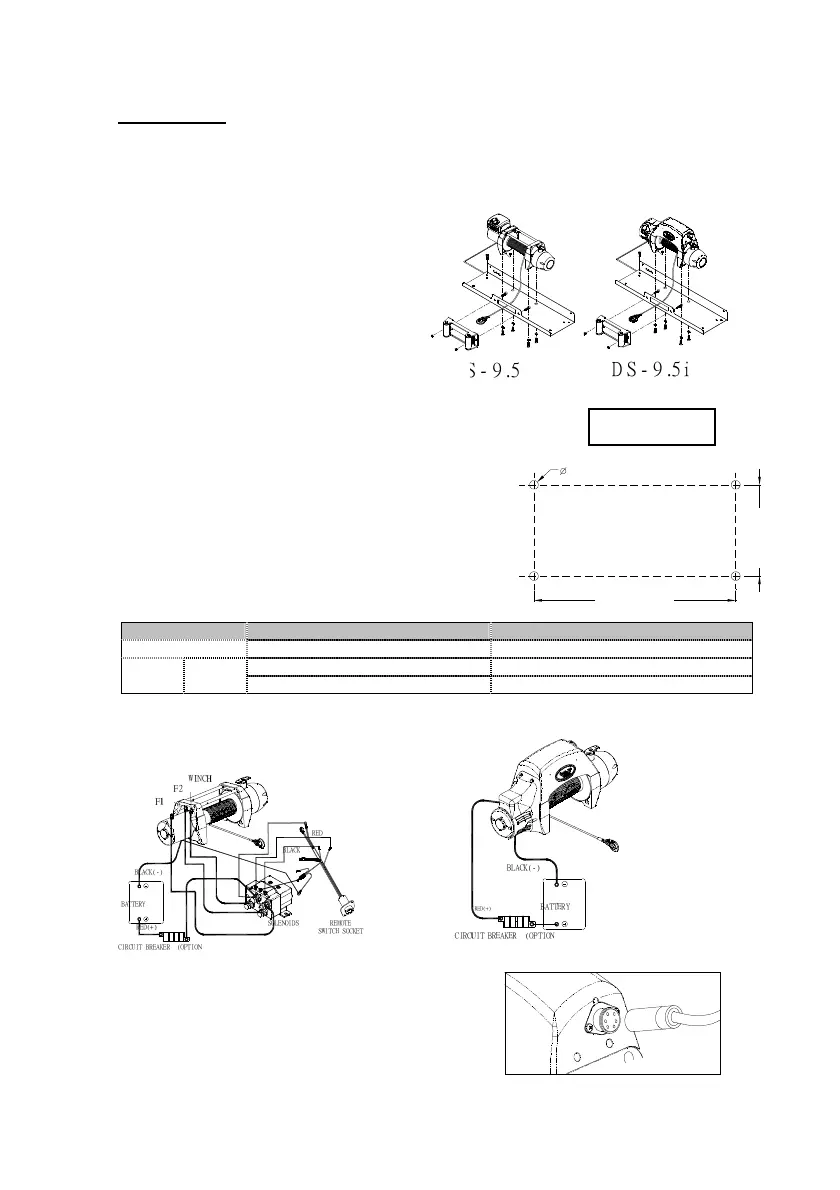

Ⅲ. Installation

Before using the winch, make sure all electrical components have no corrosion or damaged; the

environment should be clean and dry. The voltage drop from the battery connections to the winch

must not exceed 10% of the nominal voltage under normal operating condition.

Mounting

1. It is very important that the winch be

mounted on a flat and hard surface in

order to make sure the motor, drum and

gearbox housing are aligned correctly.

2. It is recommended that you use a

mounting channel to prevent from

damaging winch or vehicle.

3. Four (4) M10 x 1.50 pitch 8.8 Grade High Tensile Steel Bolts must

be used for f

astening the winch into mounting channel in

order to sustain the loads imposed on the winch mounting.

4. Two (2) M12 x 1.75 pitch 8.8 Grade High Tensile Steel

Bolts must be used for fastening the roller fairlead into

the mounting channel.

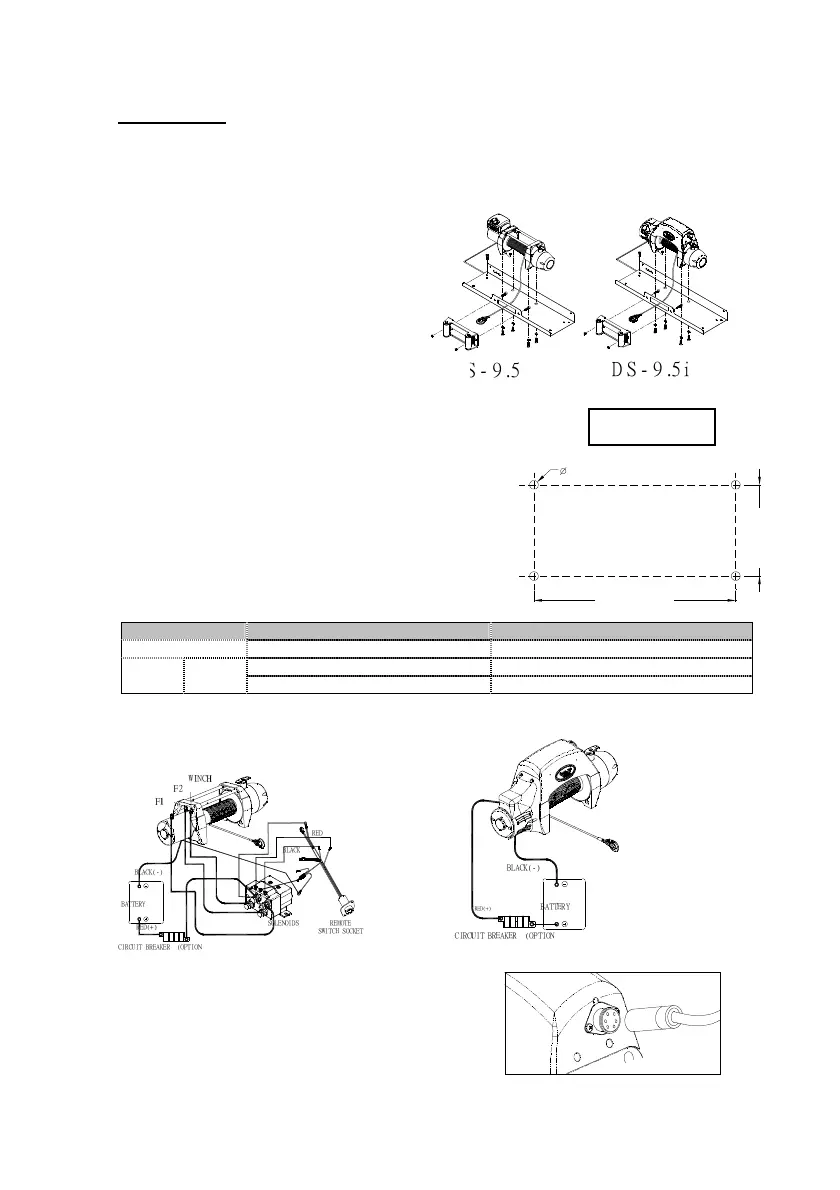

Battery Lead Connection

Battery lead specification:

Control Type Detachable solenoid pack Integrated solenoid pack

Red cable: 2 AWG x 1.83 m / 72〞 Red cable: 2 AWG x 1.83 m / 72〞

Voltage

12V or

24V

Black cable: 2 AWG x 1.83 m / 72〞 Black cable: 2 AWG x 1.83 m / 72〞

1. Attach the black lead (grounding) firmly to the negative (–) battery terminal.

2. Attach the red lead to the circuit breaker, connect the other end to the positive (+) battery

terminal.

3. The circuit breaker shall be recommended to be fitted.

DS-9.5 DS-9.5i

Switch Connection

1. A trigger switch withψ0.75 mm X 6 C X

5 m (18 AWG X 6 C X 17′) cord supplied

2. Open the dust-proof cover of the winch, then

insert the switch plug into the socket .

Foot print

Loading...

Loading...