6

Ⅲ

ⅢⅢ

Ⅲ. Installation

Before using the winch, make sure all electrical components have no corrosion or damaged; the

environment should be clean and dry. The voltage drop from the battery connections to the winch

must not exceed 10% of the nominal voltage under normal operating condition.

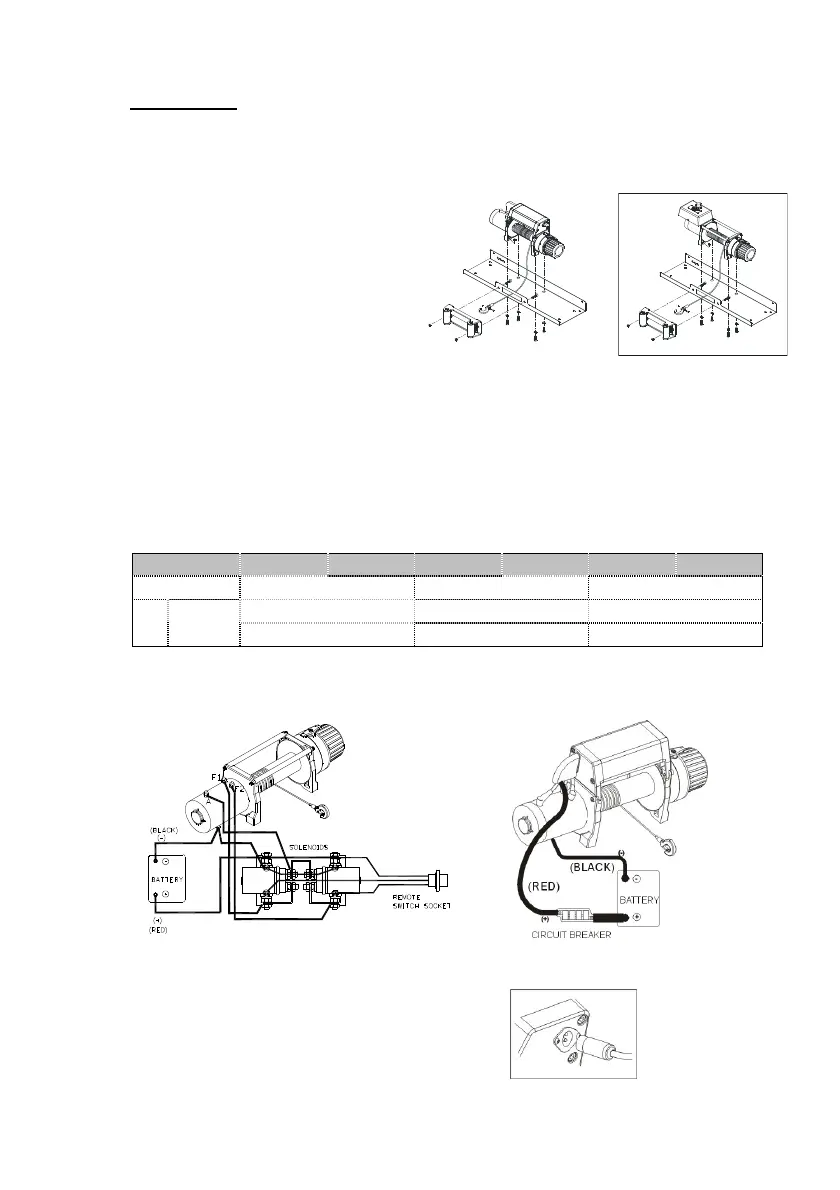

Mounting

1. It is very important that the winch

will be mounted on a flat and hard

surface, mounting channel, in

order to make sure the motor,

drum and gearbox housing are

aligned correctly.

2. The roller fairlead doesn’t mount

to winch directly.

3. Four (4) M10 x 1.50 pitch 8.8 Grade High Tensile Steel Bolts must be used for

DV-6000/9000/6000i/9000i in order to sustain the loads imposed on the winch mounting.

4. Eight (8) M12 x 1.75 pitch 8.8 Grade High Tensile Steel Bolts must be used for

DV-12000/15000 in order to sustain the load imposed on the winch mounting.

5. Two (2) M12 x 1.75 pitch 8.8 Grade High Tensile Steel Bolts must be used for fastening the

roller fairlead into the mounting channel.

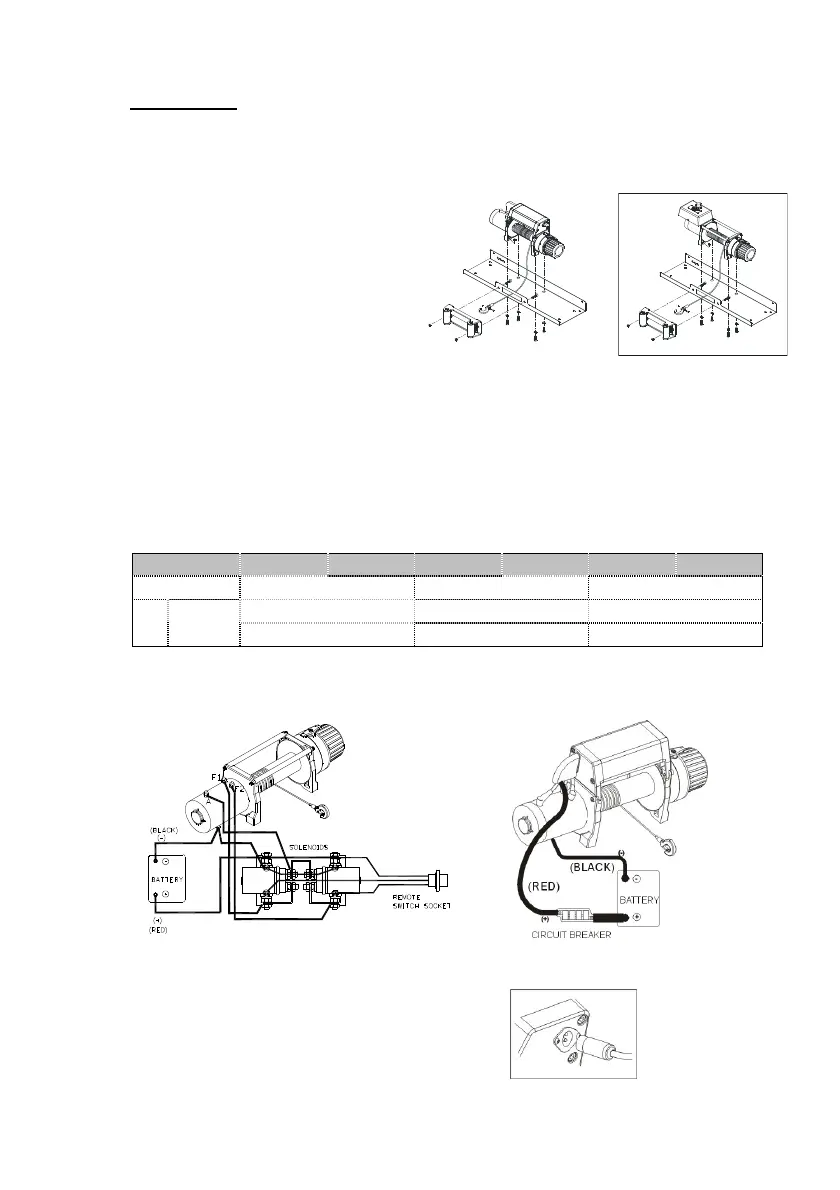

Battery leads connection

Battery leads specification:

Model DV-6000 DV-9000 DV-6000i DV-9000i DV-12000 DV-15000

Control Type Detachable solenoid pack Integrated solenoid pack Detachable solenoid pack

Red lead: 2AWG x 1.83 m/ 72” Red lead: 2AWG x 1.83 m/ 72” Red lead: 2AWG x 1.83 m/ 72”

Volt

12V or 24V

Black lead: 2AWG x 1.83 m/ 72” Black lead: 2AWG x 1.83 m/ 72” Black lead: 2AWG x 1.83 m/ 72”

1. Attach the black lead (grounding) firmly to the negative (–) battery terminal.

2. Attach the red lead to the circuit breaker, connect the other end to the positive (+) battery

terminal.

3. The circuit breaker shall be recommended to be fitted.

CIRCUIT BREAKER (OPTION) (OPTION)

DV-6000/9000/12000/15000 DV-6000i/9000i

Remote control Connection

1. A remote switch withψ1.25 mm X 3c X

5 m (16AWG X 3c X 17’) lead supplied

2. Open the dust-proof cover of the winch, then

insert the switch plug into the socket (fig3).

(Fig3)

DV-6000i / 9000i

DV-12000/15000

Loading...

Loading...