91

9.1 General maintenance

Clean the screw compressor at regular, not

too long intervals:

* Blow-clean all valves, controllers,

fittings, pressure tank, oil cooler,

radiator, screw compressor, and engine

with compressed air or a steam jet

appliance.

* Inspect the cooling ribs of the radiator to

make sure that air can pass through.

* Clean the body at regular intervals.

Then grease or oil the hinges of the

body hood with multi-purpose grease.

If sound-absorbing matting has to be

replaced, remove the retaining brackets,

replace the old sound-absorbing matting

with new matting, replace the retaining

brackets.

9.2 Engine maintenance

The maintenance of the engine is to be

carried out in accordance with the engine

operating manual.

Danger

During inspection, adjustment, or

maintenance work, remember that the

surfaces of machine parts can be hot,

particularly the exhaust system (risk

of burning) and that the control device

may move during operation (risk of

crushing).

Attention

In addition to the maintenace charts

of the KHD engine the following items of

the engine operating instruction apply

after 50 operating hours after the start-

up of new or overhauled engines:

* Check engine for leaks, repair if

necessary

* Change engine oil

* Replace oil filter cartridge

* Changing the fuel filter cartridge and

advance fuel filter

* Check tappet clearance, adjust if

necessary

* Check engine mounts, tighten if

necessary

* Check V-belt, tension if necessary

Full load speed is factory-set by the

manufacturer and must not be modified.

The idling speed must not be changed

either, as this might cause serious

damage to the screw compressor, e.g.

damage to the coupling!

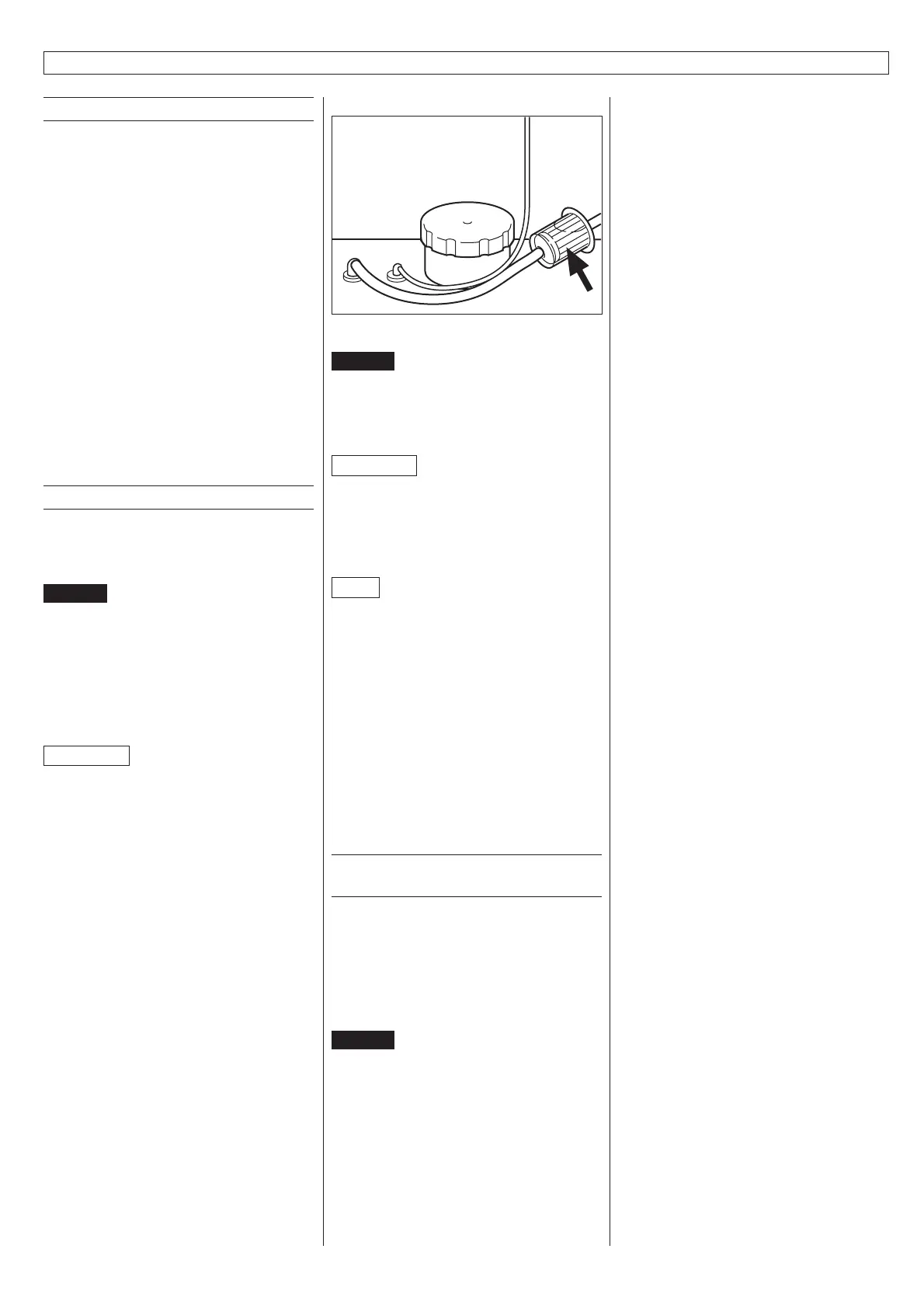

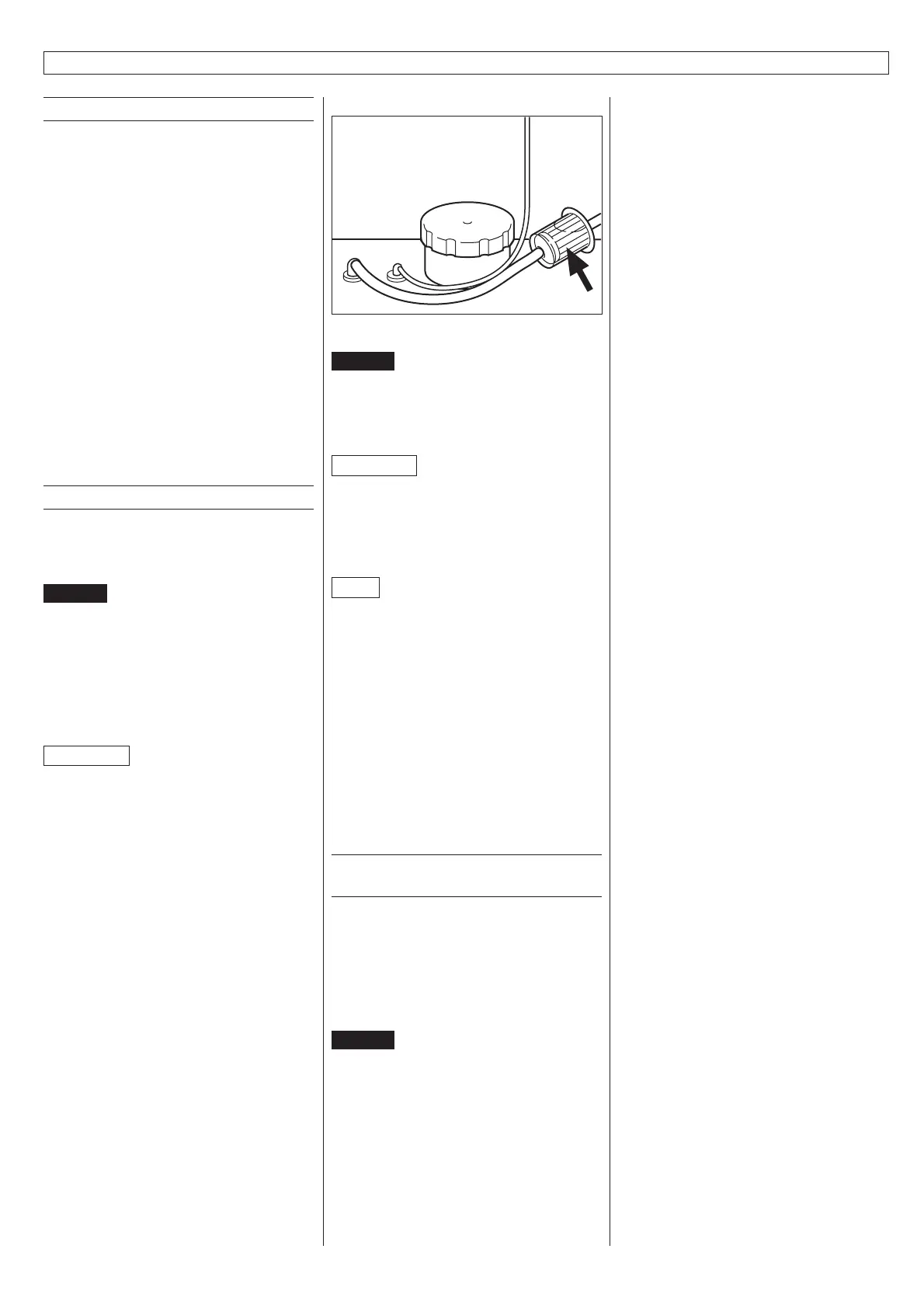

Advance fuel filter

Fig. 25

Danger

Only change filters when the engine is

at a standstill.

Do not spill fuel.

Attention

The filter changing intervals are

specified in the engine manual.

Change the advance filter more often

if there is considerable dirt.

Note

Ensure the system is free from leakage.

Check the hoses for cracks and replace

if necessary.

Dispose of contaminated filters in

accordance with the regulations.

Changing the advance fuel filter:

* Release the clamps.

* Draw the ends of the hoses off.

* Insert a new filter.

* Fit the hose ends.

* Fasten the clamps.

9.3 Maintenance of chassis and

brakes

The maintenance of the chassis and the

brakes must be carried out in accordance

with the chassis instruction manual.

Work on the brakes may only be carried

out by trained technical staff or by

specialist brake services!

Danger

During inspection, adjustment, or

maintenance work, remember that the

surfaces of machine parts can be hot,

particularly the exhaust system (risk

of burning) and that the control device

may move during operation (risk of

crushing).

9. Maintenance

Loading...

Loading...