MODEL 36, TYPE B & C

SINGLE RANGE TENSIONCELLS

INSTRUCTION MANUAL A-279

4

Copyright 2023 - Revised Comptrol All Rights Reserved

PART II - INSTALLATION AND OPERATION

II-A INSPECTION UPON DELIVERY

Comptrol Tensioncells are carefully packaged in sturdy

reinforced cartons or wooden boxes and are securely

blocked or bolted in place.

1. Upon receipt, examine the exterior of the

container for obvious damage or tampering.

2. Check the contents against the packing list.

3. Promptly report any damage or shortage to both

the carrier and Comptrol.

II-B HANDLING

Tensioncells can be handled manually.

II-C LONG TERM STORAGE

While Comptrol loadcells are plated, exposure to

weather, dirt, or moisture should be avoided when they

are stored.

II-D MECHANICAL INSTALLATION

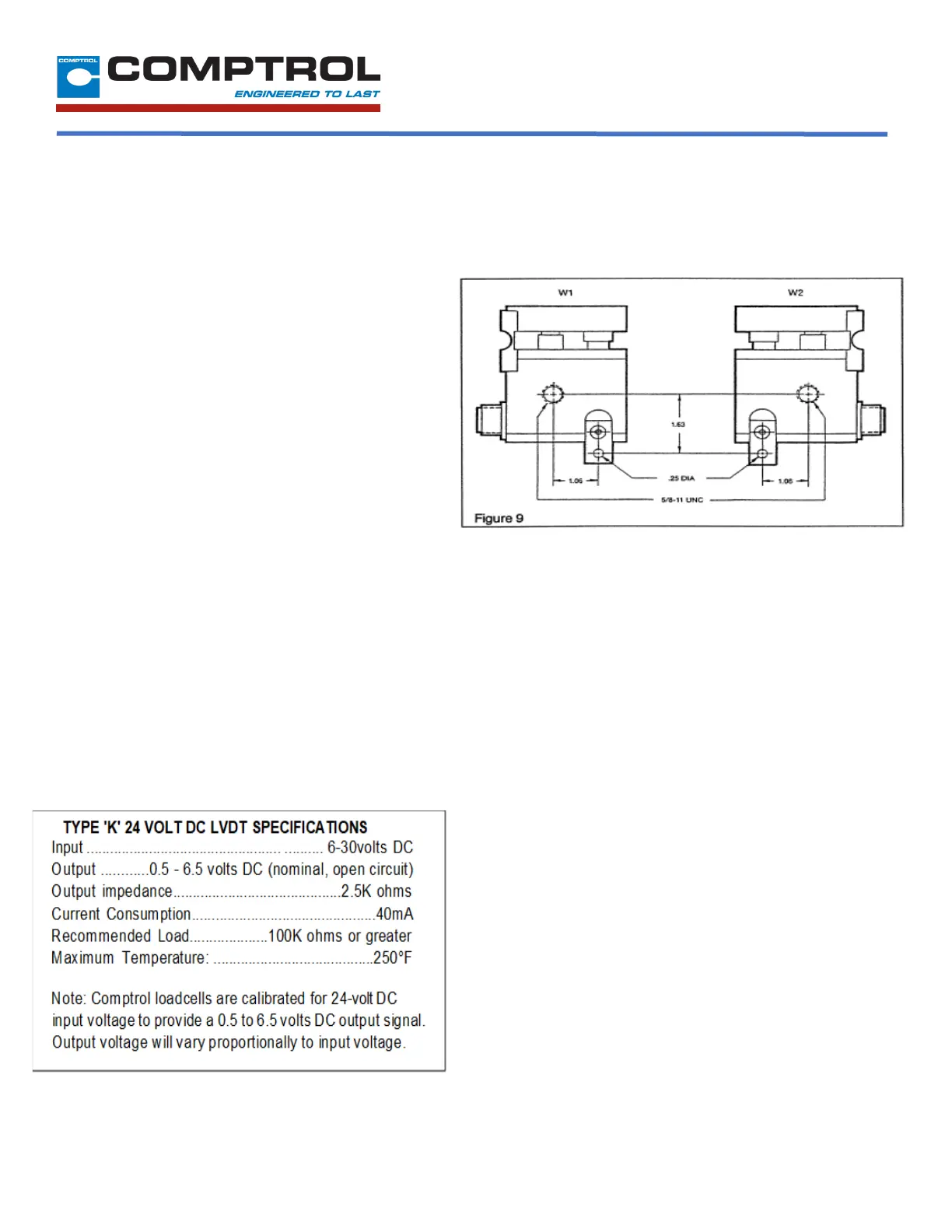

NOTE: Refer to the Dimension Drawing Page 9 of this

manual for detailed identification of all parts.

Tensioncells are designated as ‘W1” and “W2”, one

being the mirror image of the other to provide for

mounting between two fixed walls. (See Figure 9.)

Comptrol Wall Mounted Tensioncells are mounted to a

base assembly by a 5/8-11 UNC bolt which is in line with

the centerline of the measuring roll shaft. This allows the

Tensioncell to be rotated around the centers of the

measuring roll and mounting bolt to achieve the proper

mounting angle. (Description of Operation on Page 3)

A locating tab prevents the Tensioncell from rotating and

secures it in a permanent location. It also provides a

means of repeating rotatory position when the

Tensioncell needs replacement. (See Figure 9)

To Install Tensioncells:

1. Check that mounting surfaces to which the

Tensioncells are to be mounted are flat to within

.002-inch T.I.R.

2. Refer to Figure 10 for the size, location and

orientation of the Tensioncell Base Assembly

mounting holes to be drilled and tapped in the

stands or base structures.

3. Drill and tap the holes in the stand or base

mounting structure to accept the Tensioncell Base

Assembly.

4. Mount the Tensioncell Base Assembly to the stand

or base mounting structure.

5. Fasten the Tensioncell to the Base Assembly with a

5/8- 11 x1-1/4 Hex Head Cap Screw.

6. Rotate the Tensioncell to the proper mounting

angle and tighten the mounting bolt. (Refer to N on

on the calibration sheet for the proper mounting

angle)

Loading...

Loading...