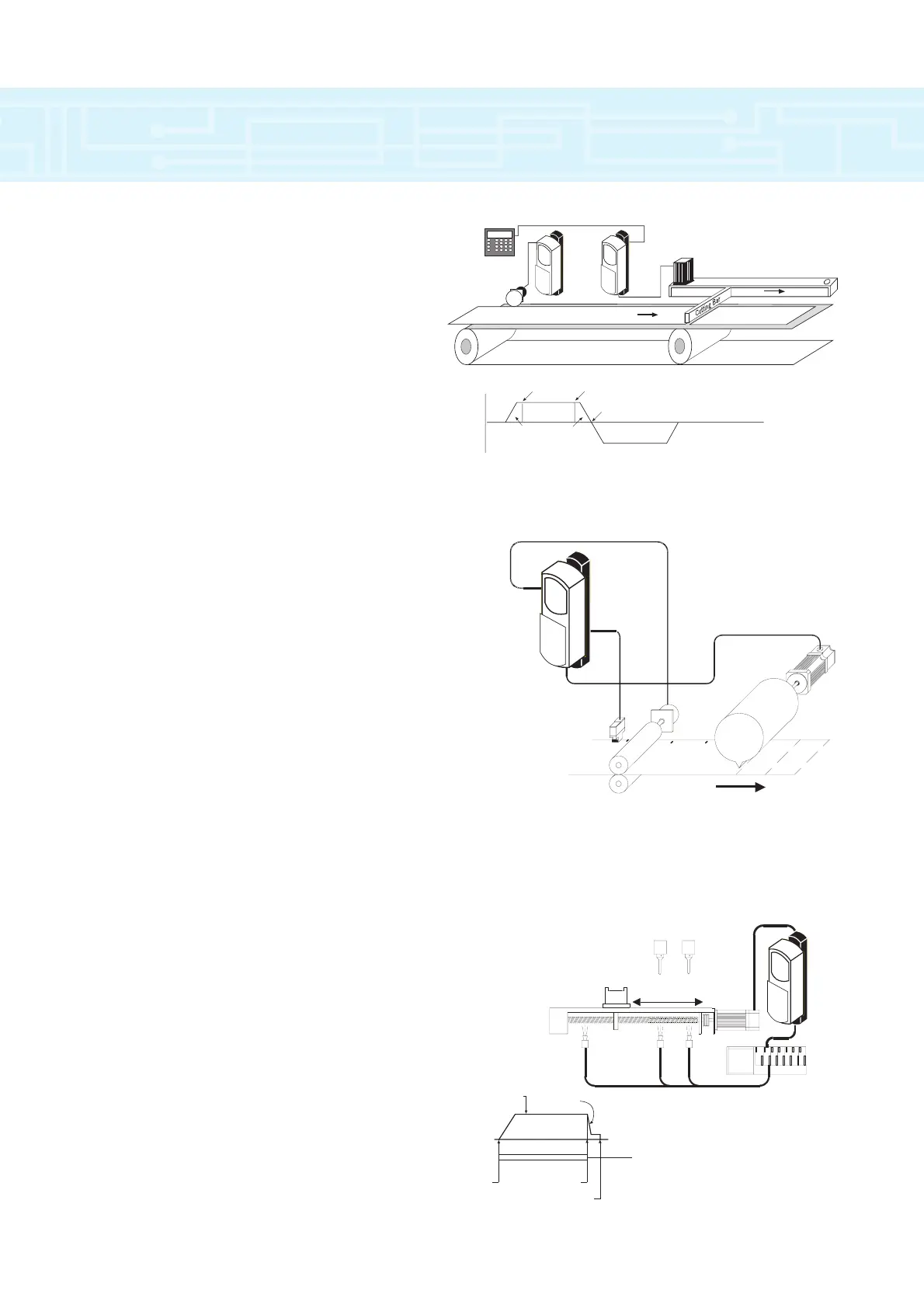

Flying Cut Off - Inline

Objective: Provide an easy method for an operator to

enter product cut lengths

Solution: Unidrive with UD70 motion profiler and CTIU

operator interface.

Operation:When the correct product length passes, the

cut bar is accelerated to match the speed of

the product. When speed is matched, an

output is activated sending the cutter head

down. The operator is able to set the length

using the CTIU operator interface.

Results: Easy data entry with fast and accurate cut cycles.

Rotary Cut Off

Objective: Cut material to user specified length and

maintain cut on the registration marks.

Solution: Unidrive with UD70 natural profiler.

Operation: the UD70 monitors the encoder position and

product registration sensor to insure that the

product is cut in the correct position. The

UD70 has the capability to learn the exact new

length of the product even if the operator

enters a length close to the correct length. Any

changes to the drive parameters can be made

on the fly.

Results: Synchronised system provides fast and

accurate cut lengths exactly placed on

registration marks.

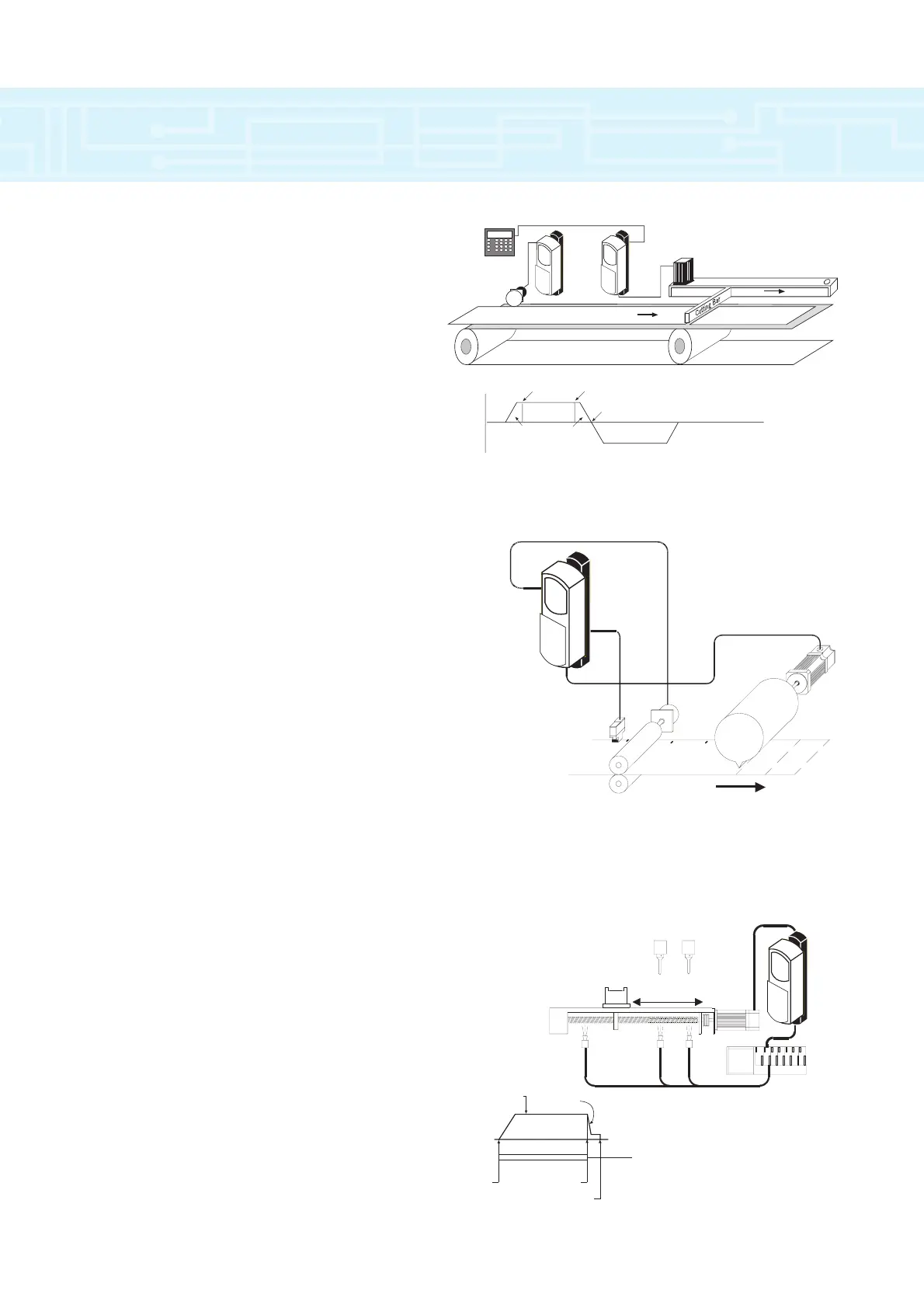

Positioning with a Unidrive

Objective: Increase accuracy and performance and

minimize cost.

Solution: Unidrive with UD70 positioner

Operation:Proximity switches are placed at the desired

drill position. The Unidrive is configured to stop

at an exact and consistant deceleration rate.

Results: Fast and accurate positioning of workpiece

with system cost minimized.

Loading...

Loading...