2GI/GR IO&M B51116-002

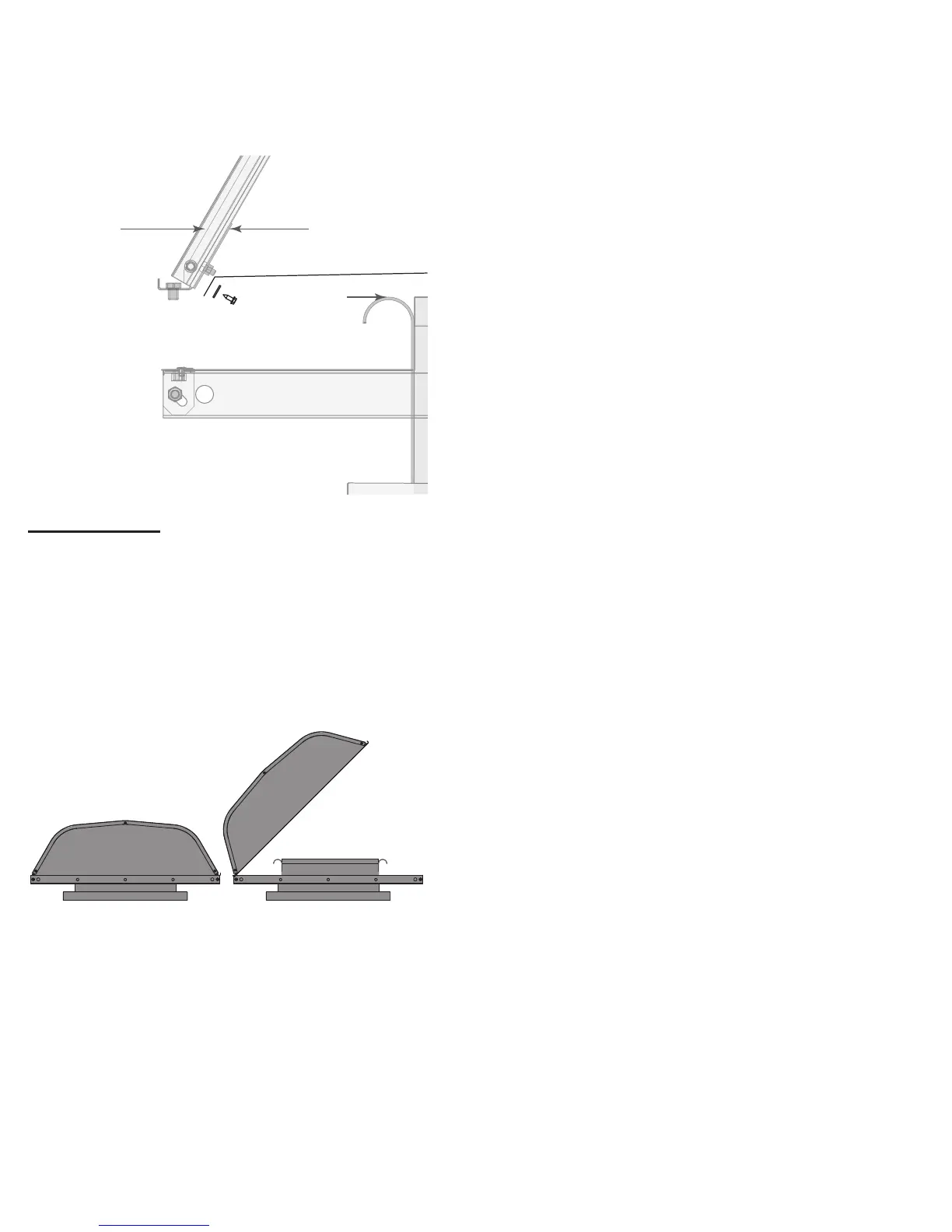

To attach the base and hood sections: set the assem-

bled hood on the assembled base, aligning the mounting

bracket holes with the holes in the section rails. Units with

support angles require the support angles to be bolted to

the base, using the bolts and nuts provided.

Figure 1

C

A

B

Section RailHood Panel

Throat

Maintenance

Hood Access

To access the throat of the unit, take the entire hood off

by removing the bolts and attaching the mounting bracket

to the mounting channels (see Figure 4). GR units with

less than a 73” throat length and GI units with less than a

61” throat length can be hinged. Hinging is accomplished

by removing the bolts on one side and loosening the two

bolts (refer to Figure 2) on the other side. Care should be

taken when hinging the hood, especially in high wind con-

ditions.

Figure 2

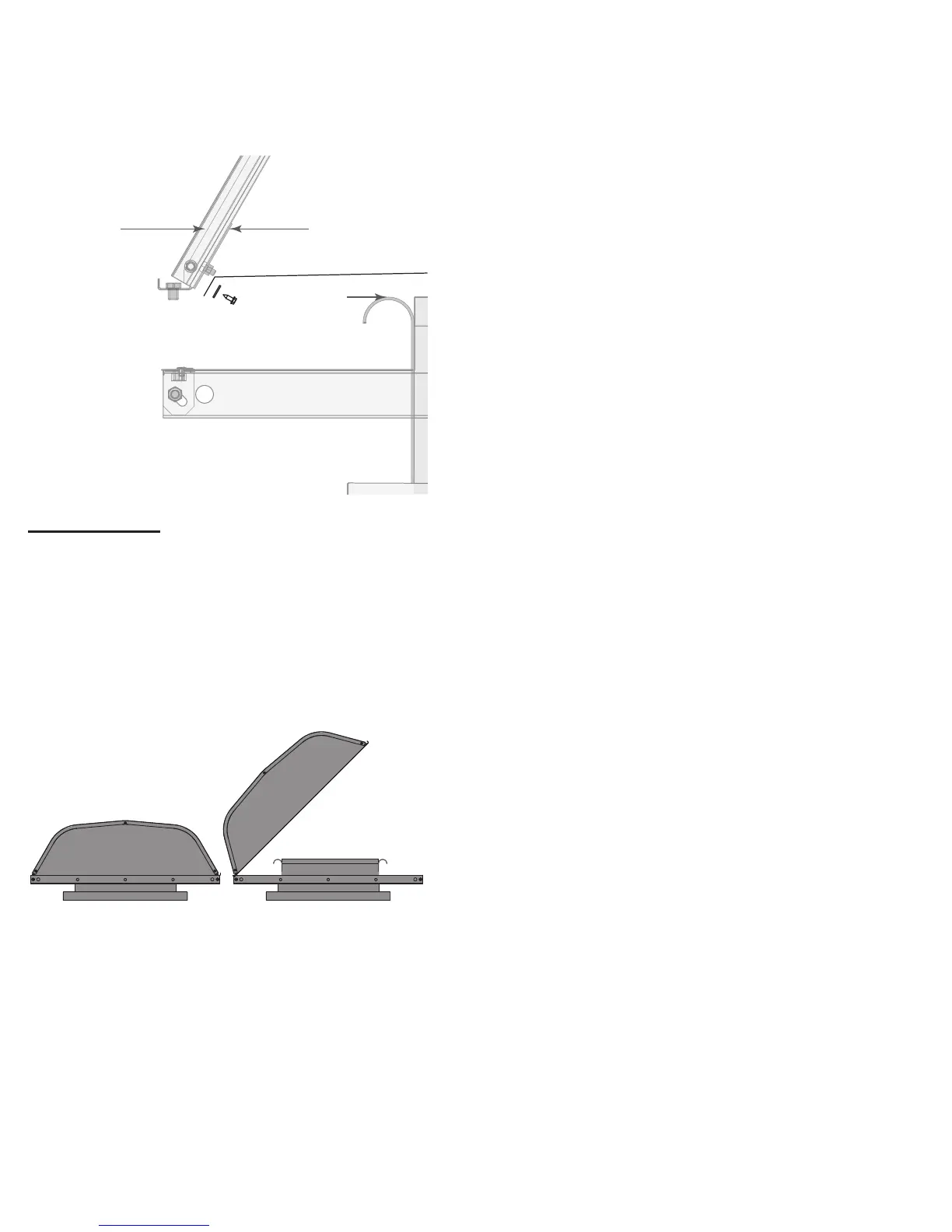

Filters

Filters are installed between the base and the hood pan-

els (see Figure 4). The lters should come in two sizes.

One size ts between the end panel and the base. The

other size is mounted between the base and the section

rail. Filter inspection and cleaning intervals can vary from

once a week to twice per year depending on contaminant

present and acceptable pressure drops across the lter.

Under most conditions lters may be cleaned with hot wa-

ter and a mild soap solution (such as dish washing liquid)

or steam. Some caustic cleaners will damage the lter. If

in doubt, please consult the factory for a compatibility list.

High pressure spray washers should be limited to 2,000

PSI operating pressure. Every attempt should be made to

remove the contaminants from the lter in a “backwash”

ow (NOTE: airow arrow on the lter frame). Once the

lter is dry, it may be returned to the appropriate lter racks

in the same orientation (airow direction) as they were re-

moved.

Loading...

Loading...