2SQN IO&M B51141-004

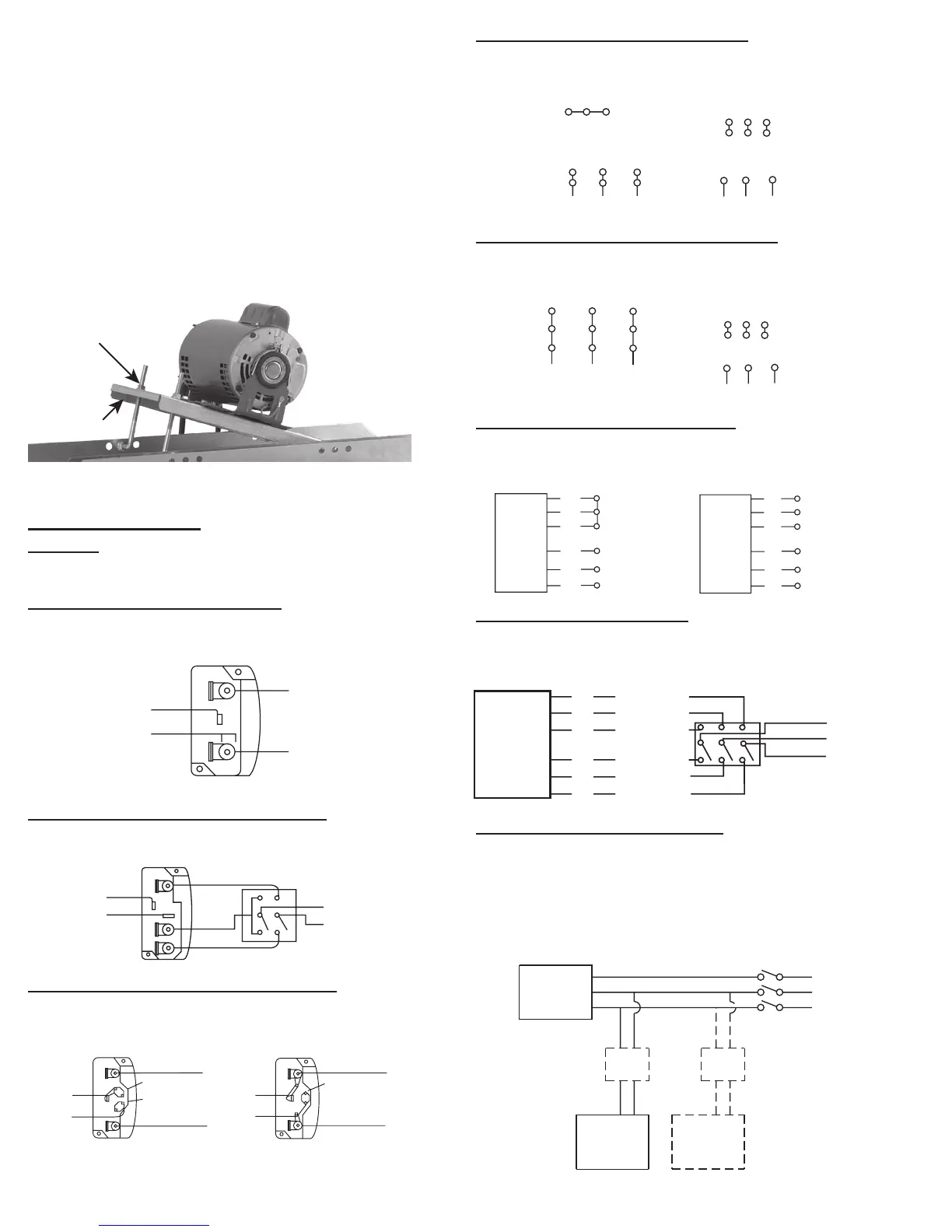

3 Phase, 9 Lead Motor Y-Connection

To reverse, interchange any 2 line leads.

4

5

6

1

7

2

8

3

9

456

7

8

9

12

3

208/230 Volts

460 Volts

3 Phase, 9 Lead Motor Delta-Connection

To reverse, interchange any 2 line leads.

7

1

6

789

4

5

6

12

3

08/230 Volts

460 Volts

8

2

4

9

3

5

L

1

L

3

L

2

2 Speed, 1 Winding, 3 Phase Motor

To reverse, interchange any 2 line leads. Motors require mag-

netic control.

Motor

1

2

3

4

5

6

Together

High Speed

Line

L

1

L

2

L

3

1

2

3

4

5

6

Open

Low Speed

L

1

L

2

L

3

Motor

2 Speed, 2 Winding, 3 Phase

To reverse: High Speed-interchange leads T11 and T12. Low

Speed-interchange leads T1 and T2. Both Speeds-interchange

any 2 line leads.

L

1

T

1

T

2

T

3

Low Speed

Low Speed

Low Speed

High Speed

High Speed

High Speed

Motor

T

13

T

12

T

11

L

2

Line

L

3

Typical Damper Motor Schematic

For 3 phase, damper motor voltage should be the same be-

tween L

1

and L

2

. For single phase application, disregard L

3

.

*Damper motors may be available in 115, 230 and 460 volt mod-

els. The damper motor nameplate voltage should be veried pri-

or to connection. **A transformer may be provided in some in-

stallations to correct the damper motor voltage to the specied

voltage.

Fan

Motor

Damper

Motor*

Second

Damper

Motor

Transformer**

Transformer**

L3

L2

L1

Storage

If the fan is stored for any length of time prior to installa-

tion, completely ll the bearings with grease or moisture-

inhibiting oil. Refer to Lubricants on page 5. Also, store the

fan in its original crate and protect it from dust, debris and

the weather.

To maintain good working condition of an SQN when it

is stored outdoors, or on a construction site, follow the ad-

ditional steps below:

• Cover the inlet and outlet, and belt tunnel opening to prevent

the accumulation of dirt and moisture in the housing.

• Periodically rotate the wheel and operate dampers (if supplied)

to keep a coating of grease on all internal bearing parts.

• Periodically inspect the unit to prevent damaging conditions.

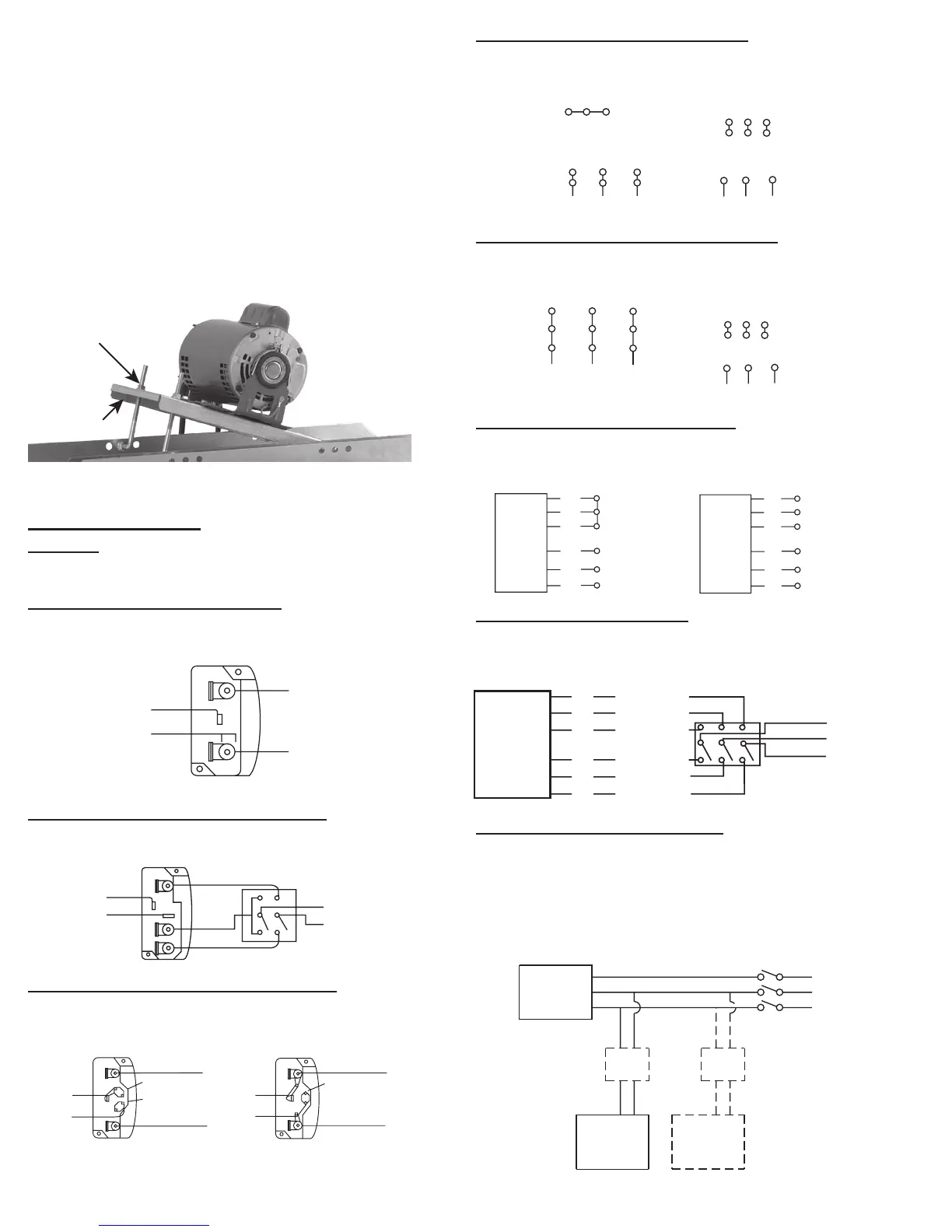

e

djustment Nut

e

Adjustment

Wiring Diagrams

Vari-Flow

For EC or VF see EC Motor Wiring supplement. For VF2 see

PM wiring supplement.

Single Speed, Single Phase Motor

When ground is required, attach to ground A or B with no. 6

thread forming screw. To reverse, interchange T-1 and T-4.

T-1

4

L

2

L

1

Line

2 Speed, 2 Winding, Single Phase Motor

When ground required, attach to ground A or B with No. 6

thread forming screw. To reverse, interchange T-1 and T-4 leads.

T-1

4

Low Speed

High Speed

L

1

L

2

Line

Single Speed, Single Phase, Dual Voltage

When ground required, attach to ground A or B with No. 6

thread forming screw. To reverse, interchange T-5 and J-10

leads.

0

T-5

Link A

Link B

Low Voltage

Line

L

2

L

1

Link A & B

L

1

L

2

Lin

T-5

J-10

Loading...

Loading...