S225-12-1

27

!

SAFETY

FOR LIFE

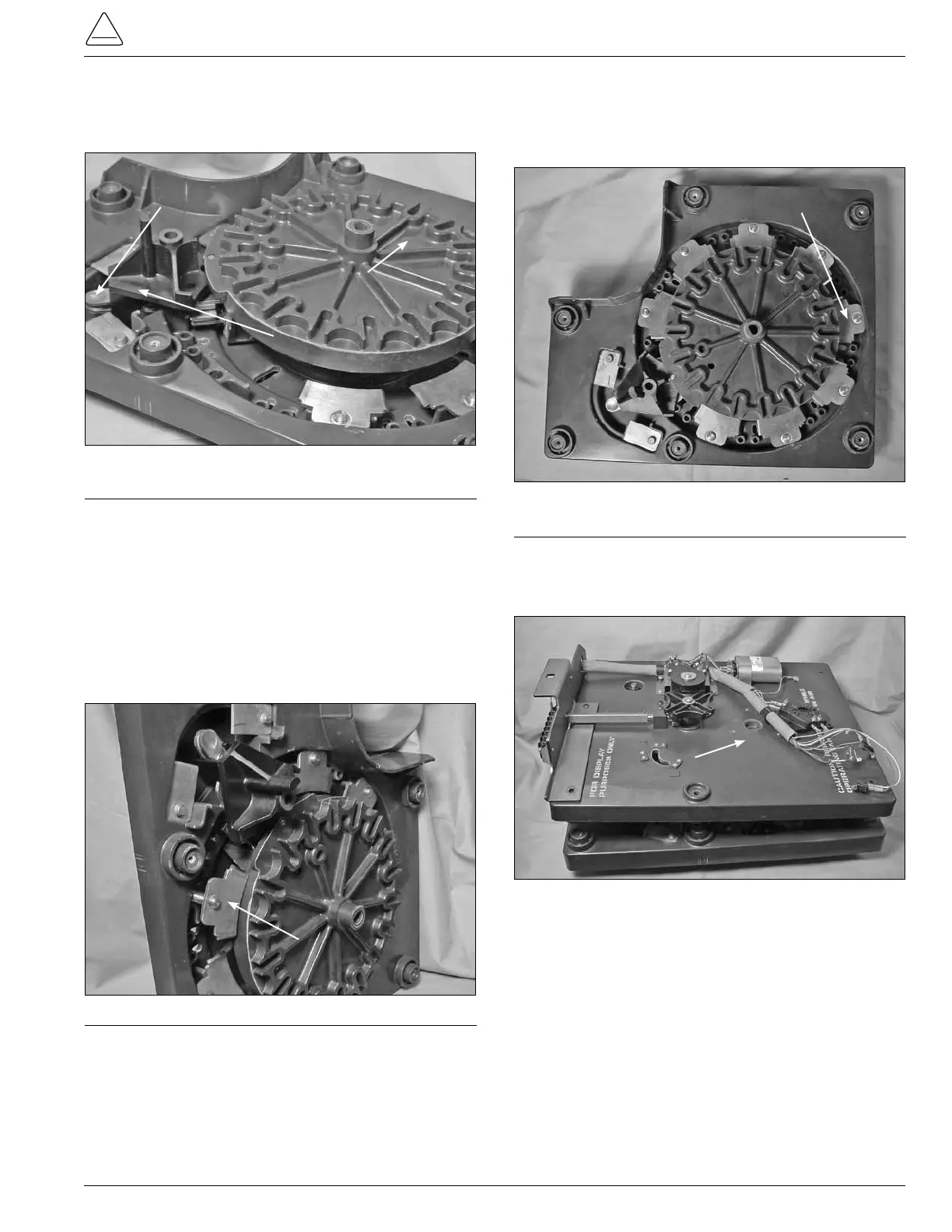

14. Rotate the main moveable contact Geneva gear

assembly onto the neutral stationary contact located

under the reversing switch assembly. (See Figure 63.)

15. Place a flat brass flat washer, external tooth lock

washer, and 3/8 nut on each of the P1 and P2 slip ring

studs and tighten with a 9/16 wrench or socket and

ratchet. Torque the nut on the studs to 60-70 pound-

inch (6.779-7.908 Nm).

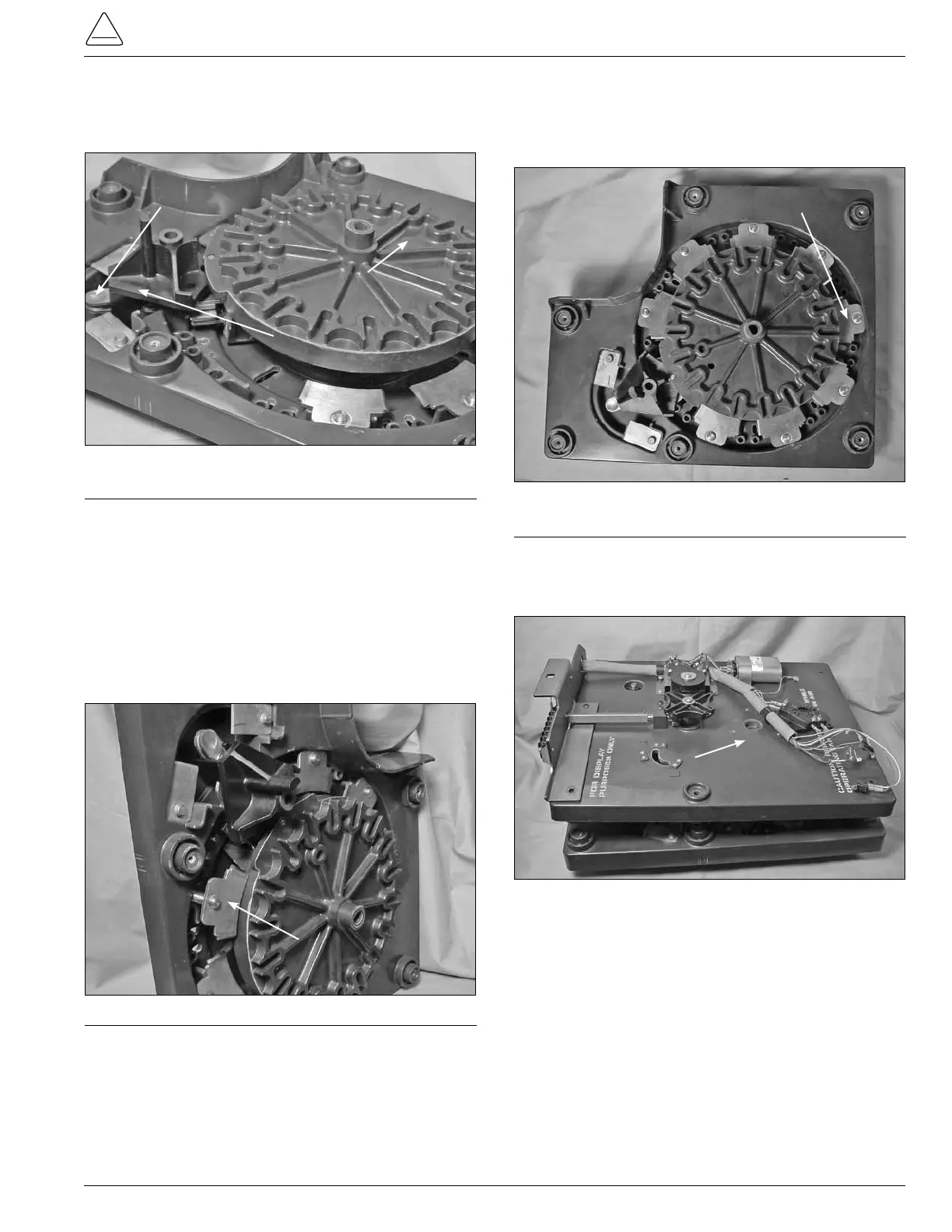

16. Replace the number 1 stationary contact by inserting

the contact stud into the contact-mounting hole in the

contact panel. The contact position number is located

on the contact panel. (See Figure 64.)

17. Place a brass flat washer, external tooth lock washer,

and nut on the number 1 stationary contact stud.

Tighten and torque the hardware 60-70 pound-inch

(6.779-7.908 Nm).

Figure 63.

Neutral position.

Moveable Contact

Assembly

Neutral Position

Reversing Moveable Contact Assembly

Figure 64.

Stationary contact one assembly.

Stationary Contact One

Tap-changer Re-Assembly

1. Lay the contact panel assembly section flat on a table

surface. (See Figure 65.)

2. Place and align the tap-changer drive assembly

section on top of the contact panel assembly. (See

Figure 66.)

Figure 65.

Stationary contact panel assembly.

Stationary Contact

Panel Assembly

Figure 66.

Tap-changer Sections.

Drive Panel Assembly

Loading...

Loading...