INSTALLATION

3

CL491 (11-04-19)

GENERAL INFORMATION

Tanks listed below are pre-charged, or filled with air at

the factory, to 40 pounds per square inch (PSI) (276kPa).

When installing tank, set tank pressure according to

Chart 1. To do this, bleed air from or add air to tank

through valve on top of tank.

NOTICE: Always set or check tank pre-charge with

NO WATER in tank or water pressure in system. If you

have already pumped water before setting or checking

pre-charge pressure, turn pump off. Open faucet until

there is no more water pressure. Set pre-charge in tank

according to Chart 1, then close faucet and turn pump

back on.

NOTICE: Replace and tighten air valve cap after

pressure is adjusted correctly. Failure to replace air

cap may allow loss of air pressure and lead to tank

waterlogging and bladder failure.

CHART 1- TANK PRECHARGE SETTINGS

When Pressure Switch

Setting Is:

Reduce Tank

Precharge (PSI) To:

20-40 PSI (138-276 kPa) 18 (124 kPa)

30-50 PSI (207-345 kPa) 28 (193 kPa)

40-60 PSI (276-414 kPa) 38 (262 kPa)

(The first number on the pressure switch is the pump

‘ON’ setting; the second number is the pump ‘OFF’

setting.)

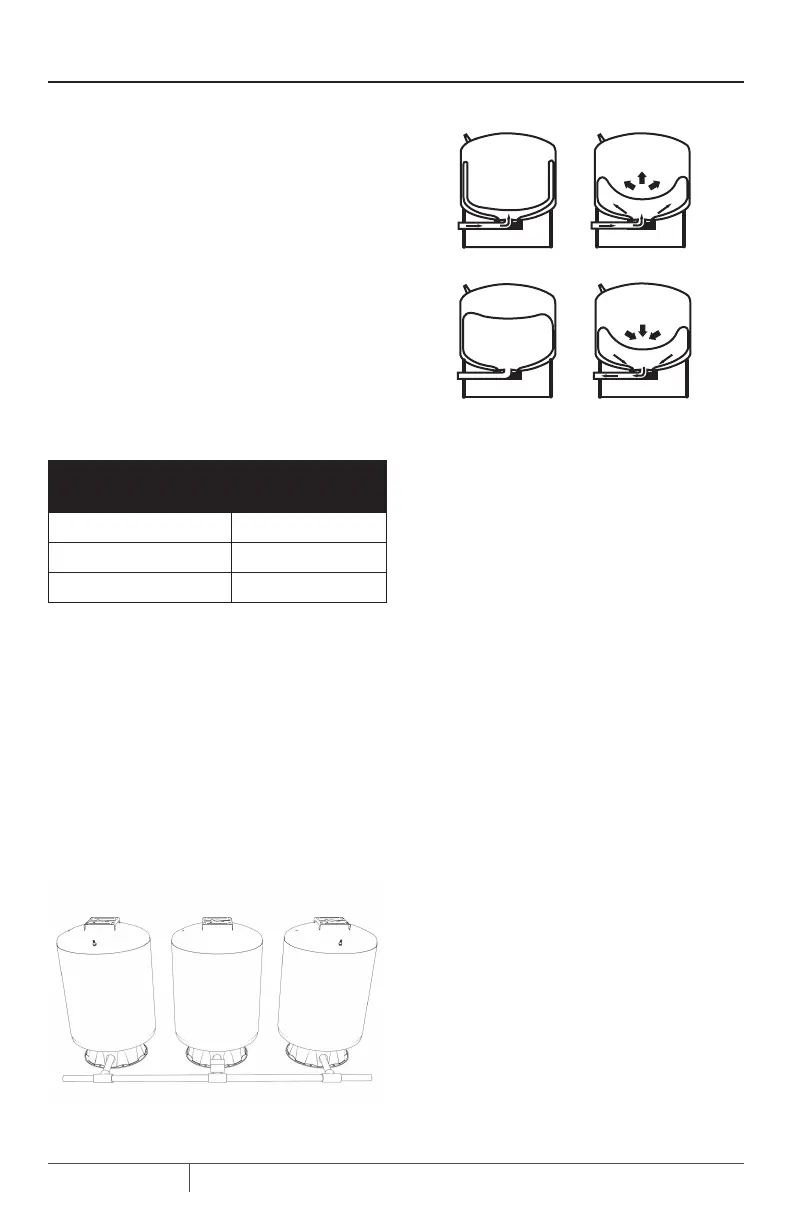

Pre-charged storage tanks can be connected together

to increase the drawdown. Drawdown is the actual

amount of usable water available from when the tank

is full to when the pump turns on. Installing two tanks

of same size will double the drawdown supply, three

tanks will triple the drawdown supply, (Figure 1). Locate

pressure switch as shown. Tank and pressure switch

cannot be more than 10’ (3M) apart.

NOTICE: Tank capacity is different than drawdown.

Tank capacity is the actual physical volume of the sheet

metalthatmakesupthetank.

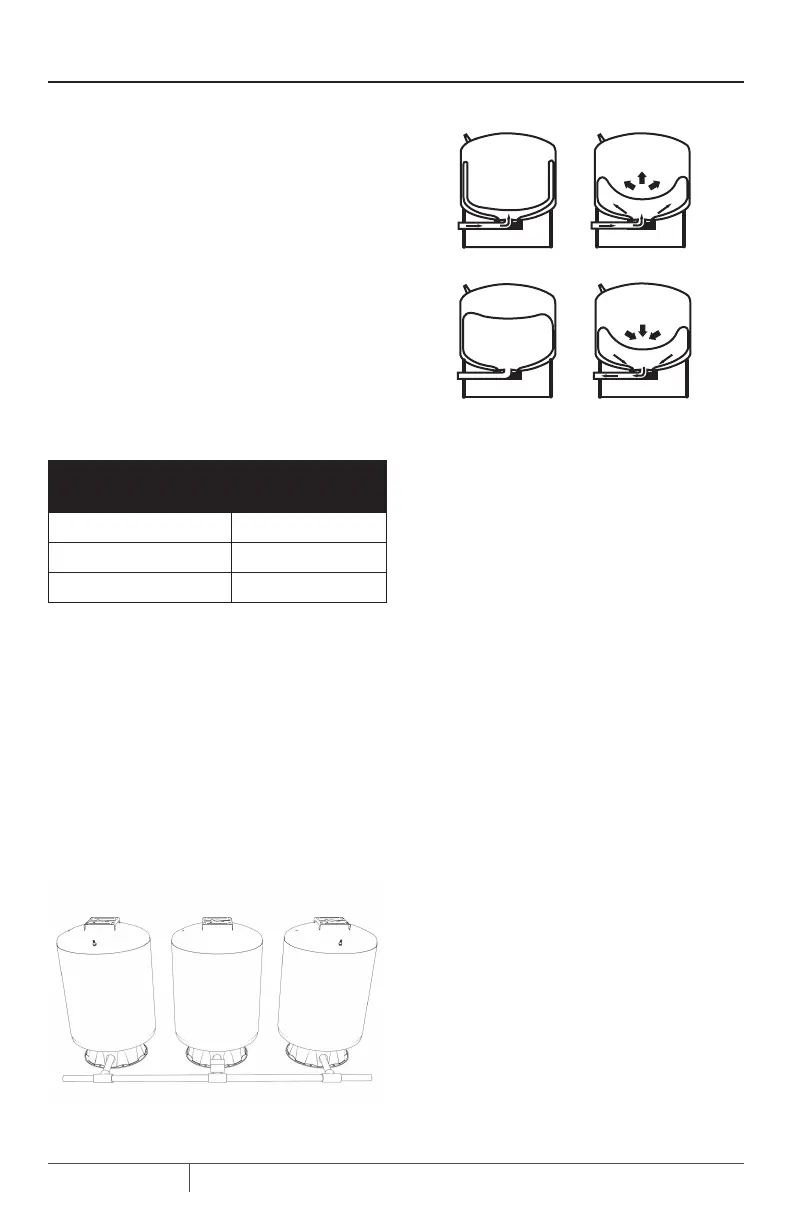

Operating Cycle

1. Tank nearly empty – air expands filling area above

bladder (Figure 2A).

2. Water enters tank – air is compressed above bladder as

it fills with water (Figure 2B).

3. Pump-up cycle completed – air compressed to OFF

setting of pressure switch (Figure 2C).

4. Water drawn from tank – compressed tank air forces

water out of bladder (Figure 2D).

5. Bladder empty – new cycle ready to begin (Figure 2A).

INSTALLATION

Connect discharge pipe from pump to a tee. Connect

one side of tee to tank flange and the other side of tee

to service. Use plastic or steel pipe as required. To

prevent leaks, use PTFE pipe thread sealant tape on

male threads of all threaded connections to tank.

NOTICE: To be sure pipe joints are not cross-threaded

and all threads are clean, make connections by hand

(without sealer) first. When threads are clean, remove

pipe, add PTFE tape, and remake connection. Tighten by

hand first; finish with pipe wrench.

When installing an elbow or nipple in the plastic tank

flange, tighten it hand tight plus 1-1/2 turns with a pipe

wrench. DO NOT OVERTIGHTEN!

Standard Tank Replacement

When replacing a standard tank in a water system with

a pre-charged tank, no bleeder orifices or Air Volume

Control (AVC) are required. When sizing a pre-charged

tank to replace a standard tank, the tanks should have

equivalent drawdowns. For example, model CLPT20

pre-charged tank has a drawdown of 5.8 gallons (22L)

and is equivalent to a 42 gallon standard tank that has a

drawdown of 4.3 gallons (16.3L).

Figure 2 - Tank Operating Cycle

WATER

WATER

WATER

Figure 1

Tanks

Loading...

Loading...