E-/

B

i

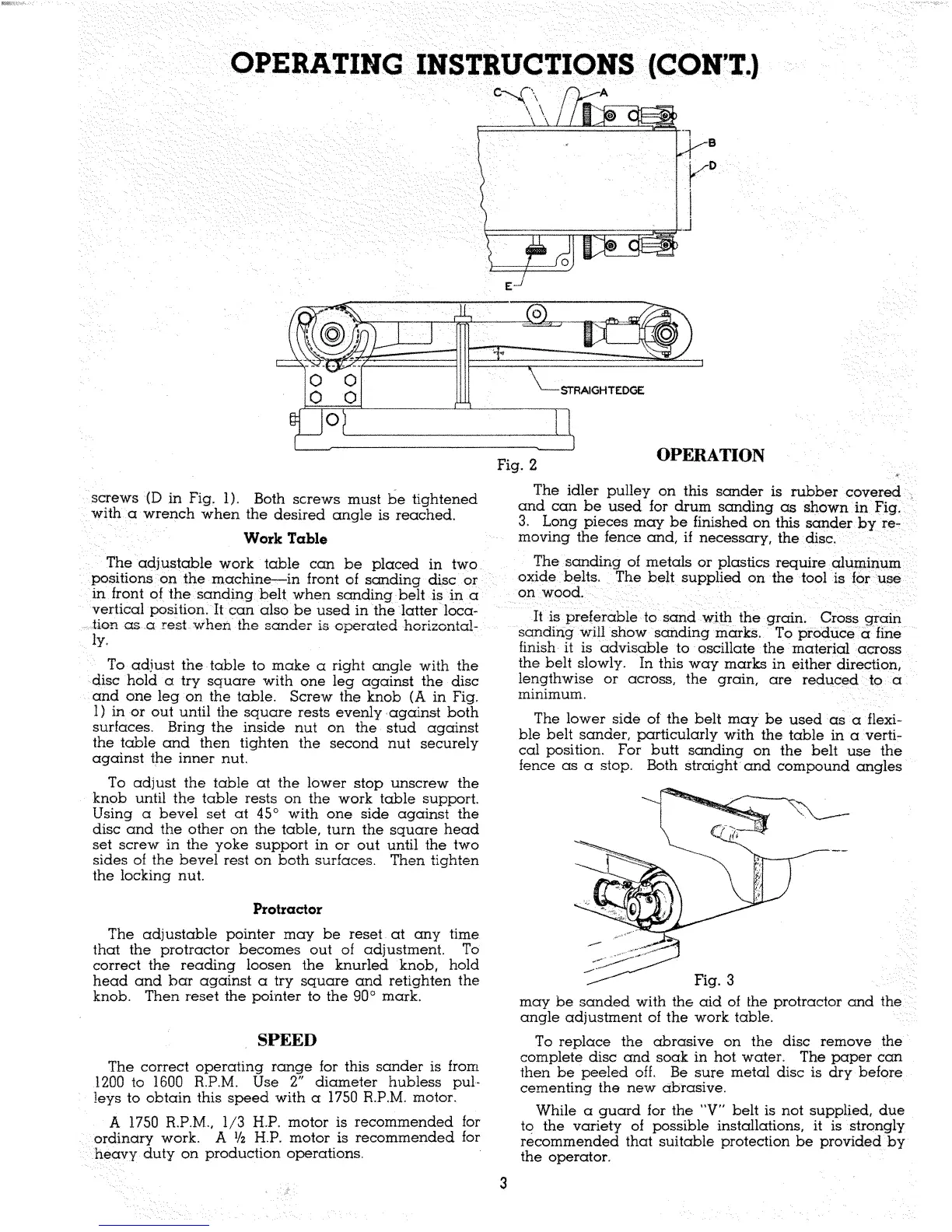

screws (D in Fig. 1). Both screws must be tightened

with a wrench when the desired angle is reached.

Work Table

The adjustable work table can be placed in two

positions on the machinein front of sanding disc or

in front of the sanding belt when sanding belt is in a

vertical position. It can also be used in the latter loca-

tion as a rest when the sander is operated horizontal-

ly.

To ad}ust the table to make a right angle with the

disc hold a try square with one leg against the disc

and one leg on the table. Screw the knob (A in Fig.

1) in or out until the square rests evenly against both

surfaces. Bring the inside nut on the stud against

the table and then tighten the second nut securely

against the inner nut.

To adjust the table at the lower stop unscrew the

knob until the table rests on the work table support.

Using a bevel set at 45 ° with one side against the

disc and the other on the table, turn the square head

set screw in the yoke support in or out until the two

sides of the bevel rest on both surfaces. Then tighten

the locking nut.

Fig. 2

OPERATION

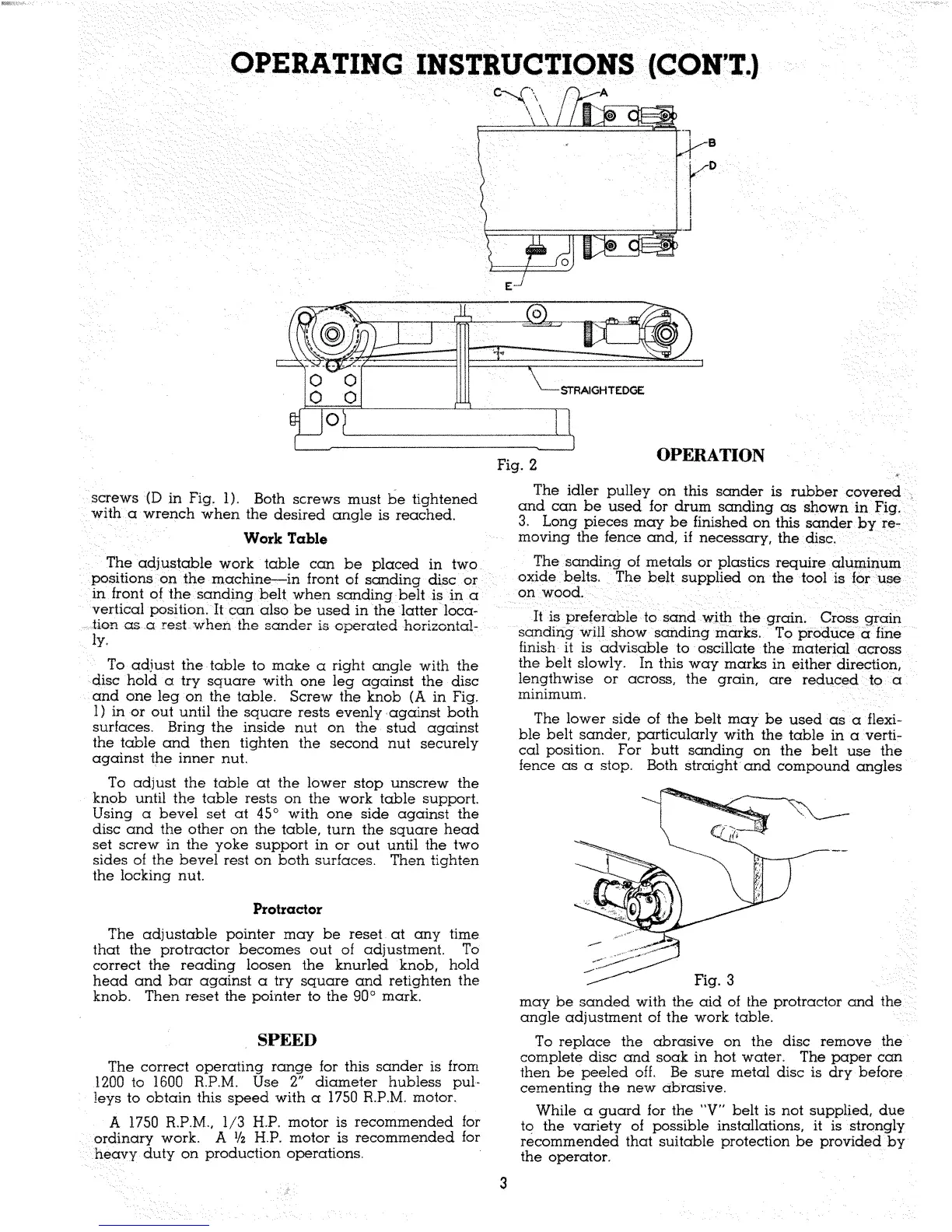

The idler pulley on this sander is rubber covered

and can be used for drum sanding as shown in Fig.

3, Long pieces may be finished on this sander by re-

moving the fence and, if necessary, the disc.

The sanding of metals or plastics require aluminum

oxide belts. The belt supplied on the tool is for use

on wood.

It is preferable to sand with the grain. Cross grain

sanding will show sanding marks. To produce a fine

finish it is advisable to oscillate the material across

the belt slowly. In this way marks in either direction,

lengthwise or across, the grain, are reduced to a

mimmum.

The lower side of the belt may be used as a flexi-

ble belt sander, particularly with the table in a verti-

cal position. For butt sanding on the belt use the

fence as a stop. Both straight and compound angles

Protractor

The adjustable pointer may be reset at any time

that the protractor becomes out of adjustment To

correct the reading loosen the knurled knob, hold

head and bar against a try square and retighten the

knob. Then reset the pointer to the 90° mark.

SPEED

The correct operating range for this sander is from

1200 to 1600 RP.M. Use 2" diameter hubless pul-

!eys to obtain this speed with a 1750 R.P.M motor.

A 1750 R,P.M, 1/3 H.P, motor is recommended for

ordinary work, A 1/2 H.P. motor is recommended for

heavy duty on production operations,

Fig. 3

may be sanded with the aid of the protractor and the

angle adjustment of the work table.

To replace the abrasive on the disc remove the

complete disc and soak in hot water. The paper can

then be peeled off. Be sure metal disc is dry before

cementing the new abrasive,

While a guard for the "V" belt is not supphed, due

to the variety of possible installations, it is strongly

recommended that suitable protection be provided by

the operator.

Loading...

Loading...