Do you have a question about the Craftsman 358.341060 and is the answer not in the manual?

Guidelines for safe chain saw operation, including user restrictions and keeping bystanders away.

Details on required protective clothing and gear for safe chain saw operation, including footwear and eye protection.

Procedure for inspecting chain saw parts for damage, alignment, and proper function before use.

Precautions for safe use of the electric chain saw, focusing on power cords and connections.

Precautions and techniques to minimize the risk of kickback during chain saw operation.

Techniques for maintaining control of the chain saw during operation, focusing on grip and body positioning.

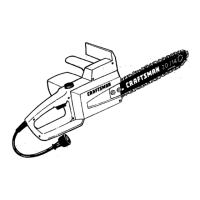

Structural barrier designed to reduce the chance of left hand contacting the chain if hand slips off the front handlebar.

Designed with distance and in-line position for balance and resistance in controlling saw pivot during kickback.

Guide bar with small radius tip reducing kickback danger zone, proven to reduce kickback seriousness.

Chain meeting kickback performance requirements of ANSI B175.1 when tested on representative chain saws.

Familiarization with chain saw controls and adjustments, reading manual and safety rules before operation.

Guidance on selecting the appropriate gauge extension cord based on length and voltage for safe operation.

Instructions for filling and maintaining the bar oil tank for proper lubrication of the guide bar and chain.

Techniques for felling large trees (6 inches diameter or larger) using the notch method and proper planning.

Techniques for cutting logs that are not supported, involving overcuts and finishing cuts.

Methods for cutting logs supported by other logs or stands, emphasizing compression side cuts.

Process of removing branches from a fallen tree, with safety precautions and techniques.

Techniques for pruning limbs, with warnings about height and proper cutting methods.

Chart outlining regular maintenance checks before, after, and during use for proper unit upkeep.

Advice on maintaining the unit as instructed to ensure warranty coverage and prevent damage or injury.

Instructions for lubricating the bar sprocket and filling the bar oil cap with Craftsman chain saw bar oil.

Guidance on checking trigger switch function and oil tank integrity, referring damage to Sears Service Center.

Procedure for checking and adjusting chain tension, ensuring it does not sag below the bar.

Distinguishing between sharp and dull chains by wood chips produced and cutting speed.

Information on obtaining special tools or professional services for chain sharpening.

Conditions requiring guide bar maintenance and replacement, including cleaning and checking for wear.

Instructions for cleaning the unit and labels using a damp cloth with mild detergent and a dry cloth.

Procedure for replacing the chain, including safety warnings and checking chain compliance with ANSI B175.1.

Advice on cleaning and lightly oiling external metal surfaces and the guide bar before storage.

The process of cross cutting a felled tree or log into lengths.

A chain saw without the saw chain and guide bar.

The process of cutting down a tree.

The final cut in a tree felling operation made on the opposite of the tree from the notching undercut.

The support handle located at or toward the front of the chain saw.

A solid railed structure that supports and guides the saw chain.

The backward or upward motion of the guide bar occurring when the saw chain contacts an object or wood.

Rapid push back of the saw when wood closes in and pinches the moving saw chain in the cut.

Rapid upward and backward motion of the saw when the moving chain contacts an object, such as a log or branch.

Chain complying with kickback performance requirements of ANSI B175.1 when tested on representative chain saws.

Positions assumed in performing the bucking and felling cuts.

A notch cut in a tree that directs the tree's fall.

A system for oiling the guide bar and saw chain.

The support handle located at or toward the rear of the saw.

Guide bar demonstrated to reduce kickback significantly.

Chain complying with kickback performance requirements of ANSI B175.1 when tested with specific chain saws.

A loop of chain having cutting teeth that cut wood, driven by the motor and supported by the guide bar.

Pointed tooth or teeth for use when felling or bucking to pivot the saw and maintain position.

Device that completes or interrupts an electrical power circuit to the motor when operated.

Mechanism that transmits motion from the trigger to the switch.

Movable stop preventing unintentional operation of the switch until manually actuated.

| Engine Type | 2-cycle |

|---|---|

| Engine Displacement | 42cc |

| Bar Length | 18 inches |

| Chain Pitch | 3/8 inch |

| Chain Gauge | 0.050 inch |

| Oil Capacity | 6.8 fl oz |

Loading...

Loading...