Do you have a question about the Craftsman Contractor 113.299112 and is the answer not in the manual?

Steps to complete before plugging in the saw for the first time.

Instructions and warnings for connecting the saw to an electrical outlet.

Instructions for converting the motor for different voltage operations.

Instructions for attaching the elevation and tilt handwheels.

Procedure to ensure the table insert is flush with the table top.

Importance and method for checking blade squareness before assembly.

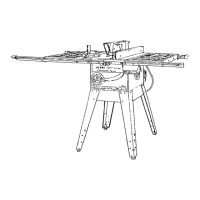

Instructions for attaching the saw housing to the assembled leg set.

Guide for attaching the table extensions to the saw table.

Alignment procedure for the front guide bar using blade marks.

Steps to install the rear guide bar for the rip fence.

Procedure for aligning the rip fence guide bars for proper operation.

How to adjust the rip fence to be parallel with the sawblade and miter gauge.

Final adjustments and troubleshooting for the micro-adjust mechanism.

Attaching the spreader and aligning antikickback pawls.

Steps for correctly positioning the motor onto its base.

Step-by-step guide for assembling the saw's leg set.

Safe techniques for feeding workpieces and avoiding injury.

Precautions to follow while the saw is operating.

Adjusting the rear and front trunnions for blade parallelism.

Adjusting stop screws and scales for 45-degree blade tilt.

Common problems and their solutions for general saw operation.

Troubleshooting for motor starting, overheating, and stalling issues.

| Type | Table Saw |

|---|---|

| Blade Diameter | 10 inches |

| Arbor Size | 5/8 inch |

| Motor | 1.5 HP |

| Voltage | 120V |

| No Load Speed | 5000 RPM |

| Max Cut Depth at 90° | 3 inches |

| Rip Capacity | 25 inches |

| Amps | 15 Amps |

Loading...

Loading...