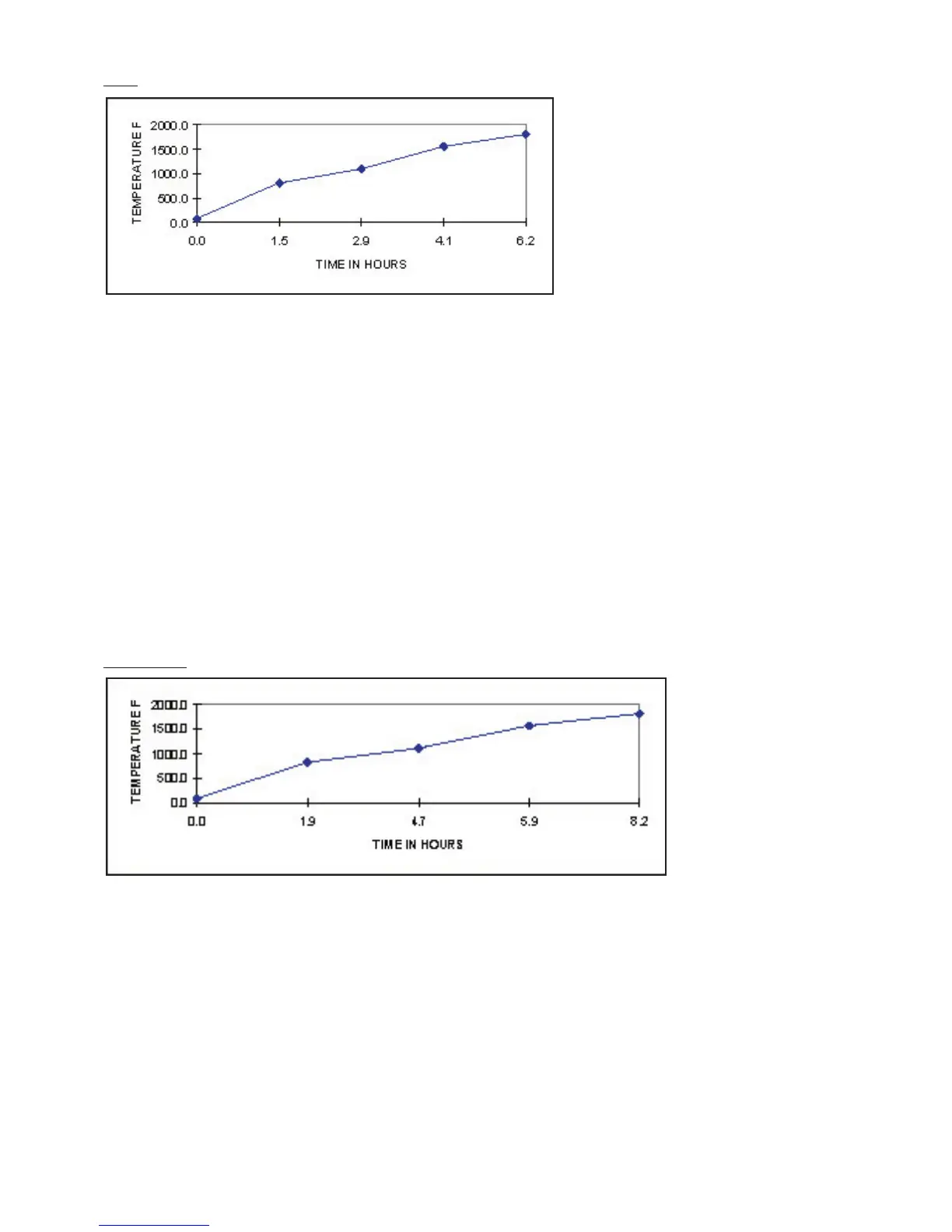

MED (cone 06 example)

500°F per hour temperature rise until the kiln reaches 1000°F, then 200°F per hour until the kiln reaches 1100°F,

then 400°F per hour until the final 250°F of the firing, then 120°F per hour until the setpoint is reached.

The segment profile chart for MED is:

SEGMENT RATE TEMPERATURE HOLD TIME (HH:MM)

1 500

°F 1000 °F 0

2 200

°F 1100 °F 0

3 400 °F 250 °F below setpoint 0

4 120 °F setpoint

Firing time varies according to density of load and cone selected. Examples of the type of ware most often fired at this speed

would be low fire glazes, thick greenware, or cast earthenware.

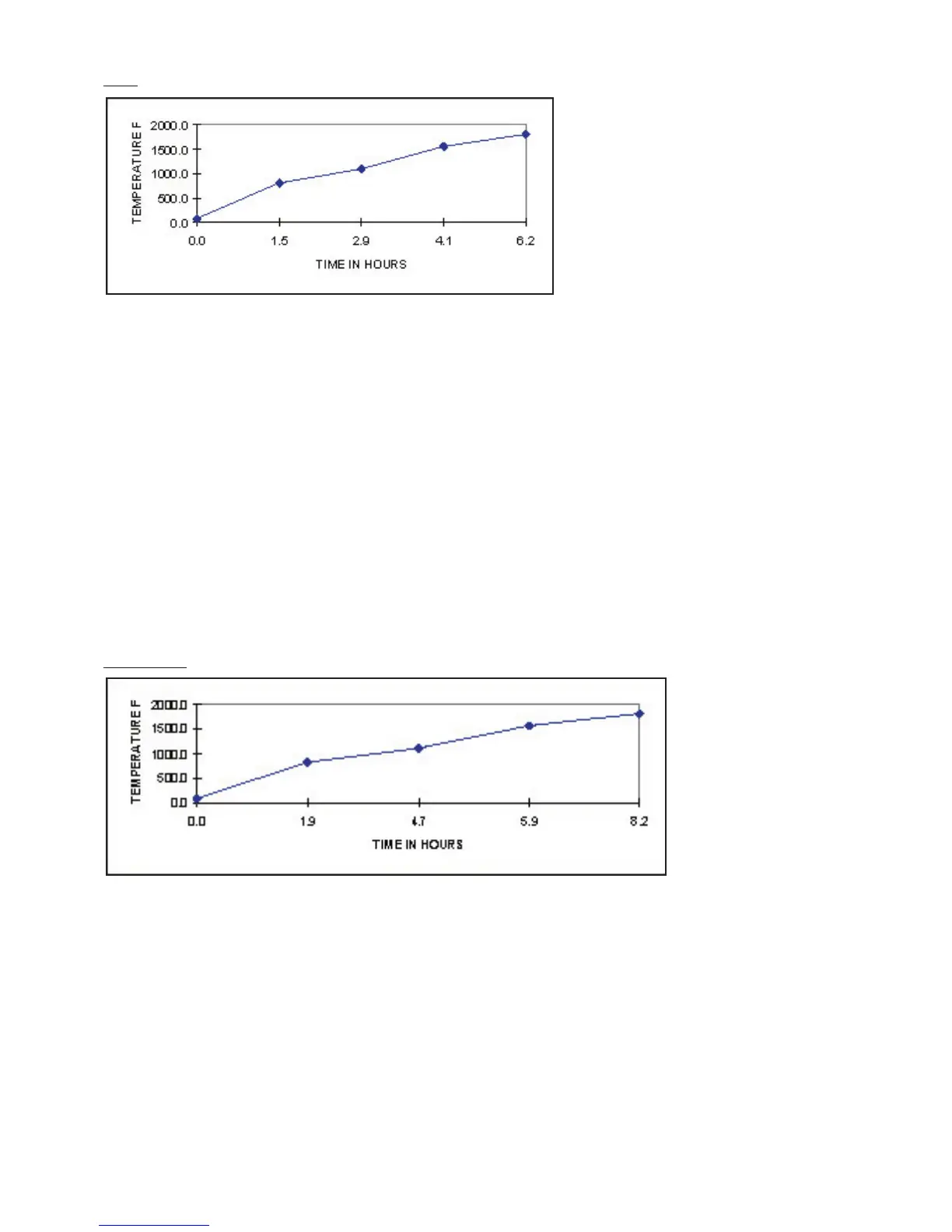

MED-SLOW (cone 06 example)

400°F per hour temperature rise until the kiln reaches 1000°F, then 100°F per hour until the kiln reaches

1100

°F, then 400°F per hour until the final 250°F of the firing, then 108°F per hour until the setpoint is reached.

The segment profile chart for MED-SLOW is:

SEGMENT RATE TEMPERATURE HOLD TIME (HH:MM)

1 400

°F 1000 °F 0

2 100 °F 1100 °F 0

3 400 °F 250 °F below setpoint 0

4 108 °F setpoint

Firing time varies according to load density and cone selected.

10

Loading...

Loading...