ELECTRIC LIFT

OPERATING INSTRUCTIONS

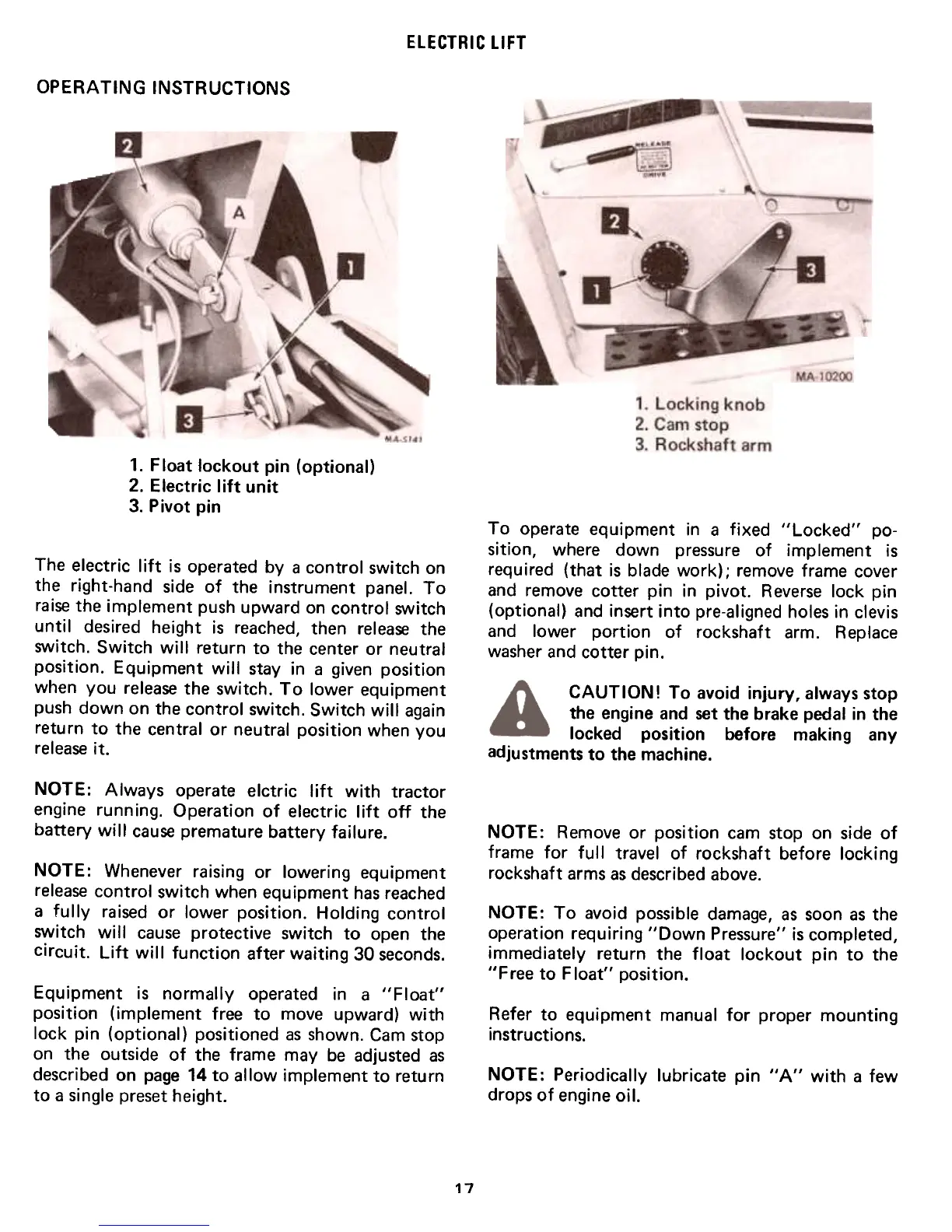

1. Float lockout pin (optional)2.

Electric lift unit3.

Pivot pin

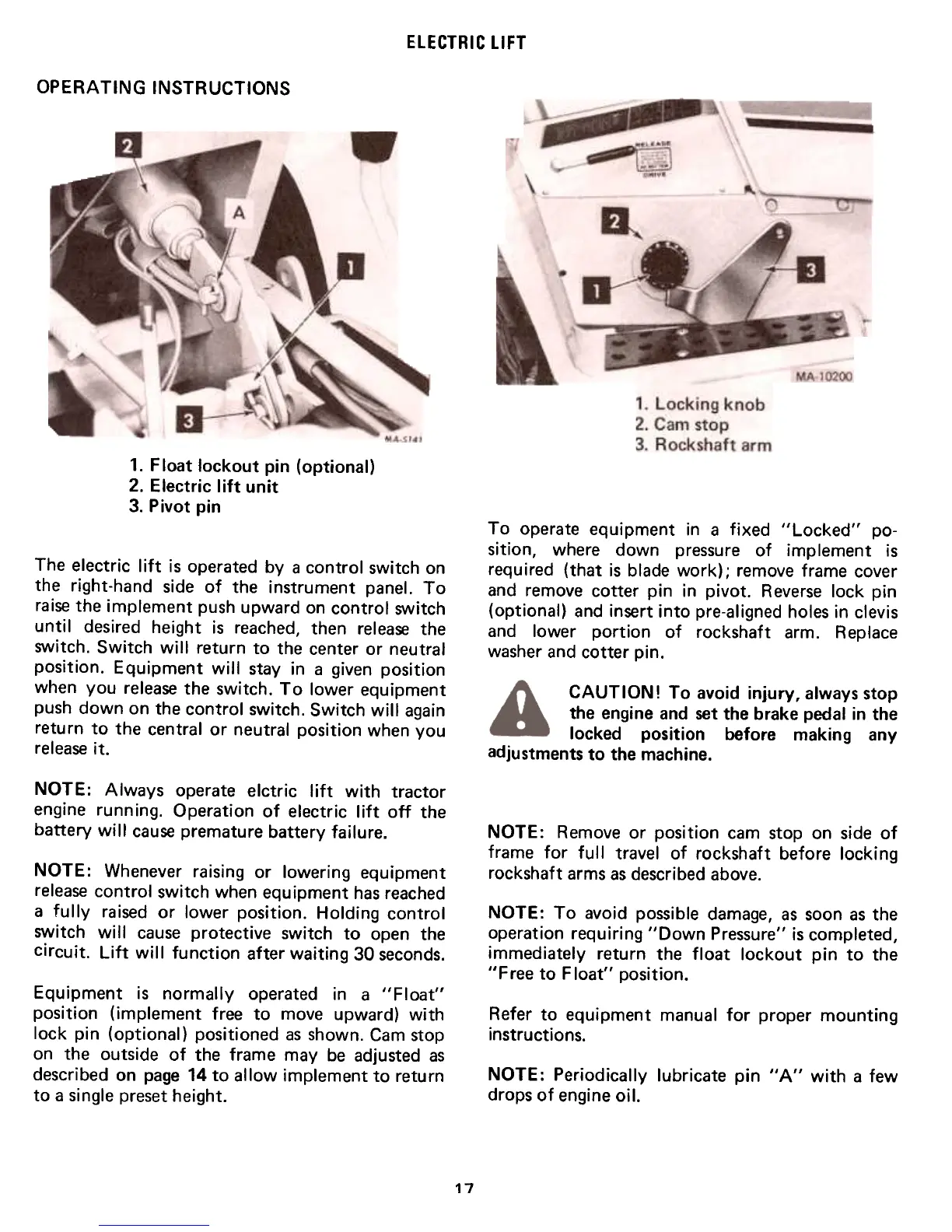

To operate equipment in a fixed "locked" po-

sition, where down pressure of implement is

required (that is blade work); remove frame cover

and remove cotter pin in pivot. Reverse lock pin

(optional) and insert into pre-aligned holes in clevis

and lower portion of rockshaft arm. Replace

washer and cotter pin.

The electric lift is operated by a control switch on

the right-hand side of the instrument panel. To

raise the implement push upward on control switch

until desired height is reached, then release the

switch. Switch will return to the center or neutral

position. Equipment will stay in a given position

when you release the switch. To lower equipment

push down on the control switch. Switch will again

return to the central or neutral position when you

release it.

CAUTION! To avoid injury, always stop

the engine and set the brake pedal in the

locked position before making any

adjustments to the machine.

NOTE: Always operate elctric lift with tractorengine

running. Operation of electric lift off the

battery will cause premature battery failure.

NOTE: Remove or position cam stop on side of

frame for full travel of rockshaft before locking

rockshaft arms as described above.

NOTE: Whenever raising or lowering equipment

release control switch when equipment has reached

a fully raised or lower position. Holding control

switch will cause protective switch to open thecircuit.

Lift will function after waiting 30 seconds.

NOTE: To avoid possible damage, as soon as the

operation requiring "Down Pressure" is completed,

immediately return the float lockout pin to the

"Free to Float" position.

Equipment is normally operated in a "Float"

position (implement free to move upward) with

lock pin (optional) positioned as shown. Cam stop

on the outside of the frame may be adjusted as

described on page 14 to allow implement to return

to a single preset height.

Refer to equipment manual for proper mounting

instructions.

NOTE: Periodically lubricate pin "A" with a few

drops of engine oil.

17

Loading...

Loading...