Operation(continued)

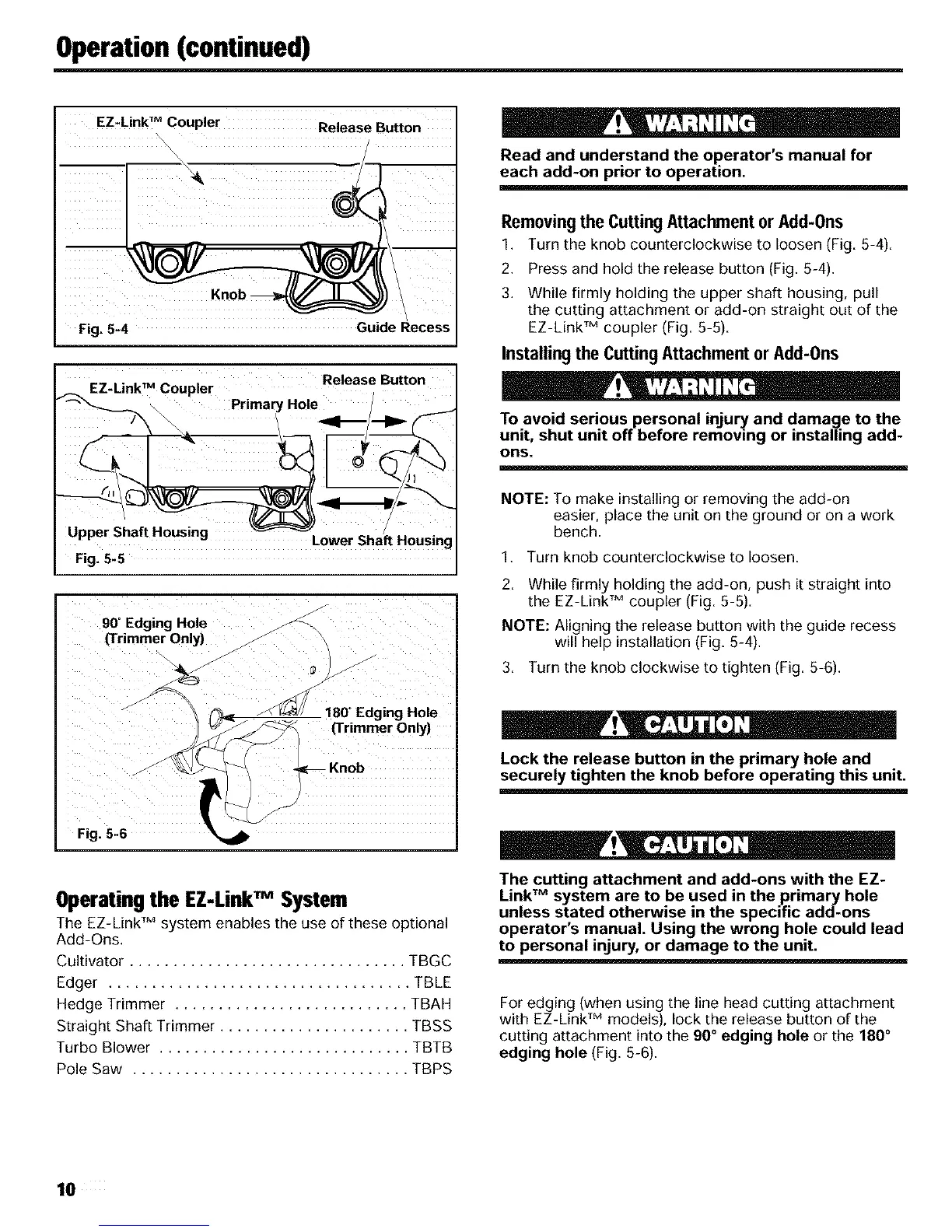

EZ-LinkT M coupler Release Button

Fig. 5-4 Guide Recess

Ez.LinkTMc0uPier Release Button

, /

Upper Shaft Housing ........

Lower _na_ Housm!

Fig. 5-5

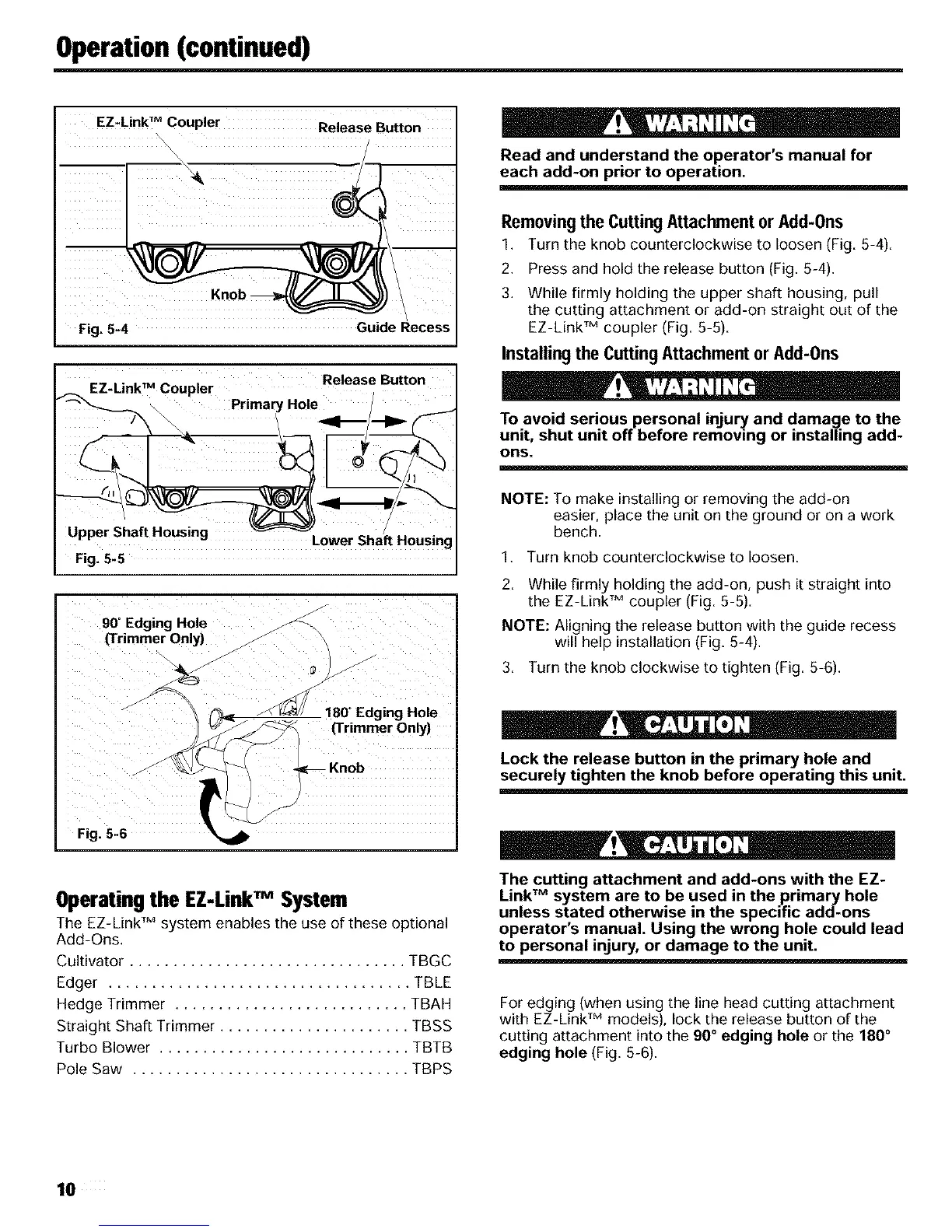

90_Edging Hole

(Trimmer Only)

Fig. 5-6 L

180°Edging Hole

(Trimmer Only)

Knob

Operating the EZ-LinkTM System

The EZ-Link TM system enables the use of these optional

Add-Ons.

Cultivator ................................ TBGC

Edger ................................... TBLE

Hedge Trimmer ........................... TBAH

Straight Shaft Trimmer ...................... TBSS

Turbo Blower ............................. TBTB

Pole Saw ................................ TBPS

! ''L

Read and understand the operator's manual for

each add-on prior to operation.

Removingthe Cutting Attachment or Add-0ns

1. Turn the knob counterclockwise to loosen (Fig. 5-4).

2. Press and hold the release button (Fig. 5-4).

3. While firmly holding the upper shaft housing, pull

the cutting attachment or add-on straight out of the

EZ-Link TM coupler (Fig. 5-5).

Installing the Cutting Attachment or Add-0ns

!

To avoid serious personal injury and damage to the

unit, shut unit off before removing or installing add-

ons.

NOTE: To make installing or removing the add-on

easier, place the unit on the ground or on a work

bench.

1. Turn knob counterclockwise to loosen.

2. While firmly holding the add-on, push it straight into

the EZ-Link TM coupler (Fig. 5-5).

NOTE: Aligning the release button with the guide recess

will help installation (Fig. 5-4).

3. Turn the knob clockwise to tighten (Fig. 5-6).

_l!llr! , o

Lock the release button in the primary hole and

securely tighten the knob before operating this unit.

! • ,

The cutting attachment and add-ons with the EZ-

LinkTM system are to be used in the primary hole

unless stated otherwise in the specific add-ons

operator's manual. Using the wrong hole could lead

to personal injury, or damage to the unit.

For edging (when using the line head cutting attachment

with EZ-Link TM models), lock the release button of the

cutting attachment into the 90° edging hole or the 180 °

edging hole (Fig. 5-6).

10

Loading...

Loading...