21se c t i O n 6 — Ma i n t e n a n c e & ad j u s t M e n t s

2.

an equivalent No. 2 multipurpose lithium grease through

the steering shaft lube fitting.

Deck Wheels

fitting. Lubricate with a No. 2 multi-purpose grease applied with a

grease gun after every 25 hours of tractor operation.

Pivot Points & Linkage

Lubricate all the pivot points on the drive system, parking brake

and lift linkage at least once a season with light oil.

Adjustments

WARNING!

ignition key and engage the parking brake before

heavy gloves when handling the blades.

NOTE:

any deck leveling adjustments. Refer to Tires on page 25 for

information regarding tire pressure.

Seat Adjustment

adjustment instructions.

WARNING!

the seat is engaged in the seat-stop. Engage the

back on seat until it clicks into place.

Parking Brake Adjustment

If the tractor does not come to a complete stop when the brake

roll with the parking brake applied (and the hydrostatic relief

Cadet dealer to have the brake adjusted.

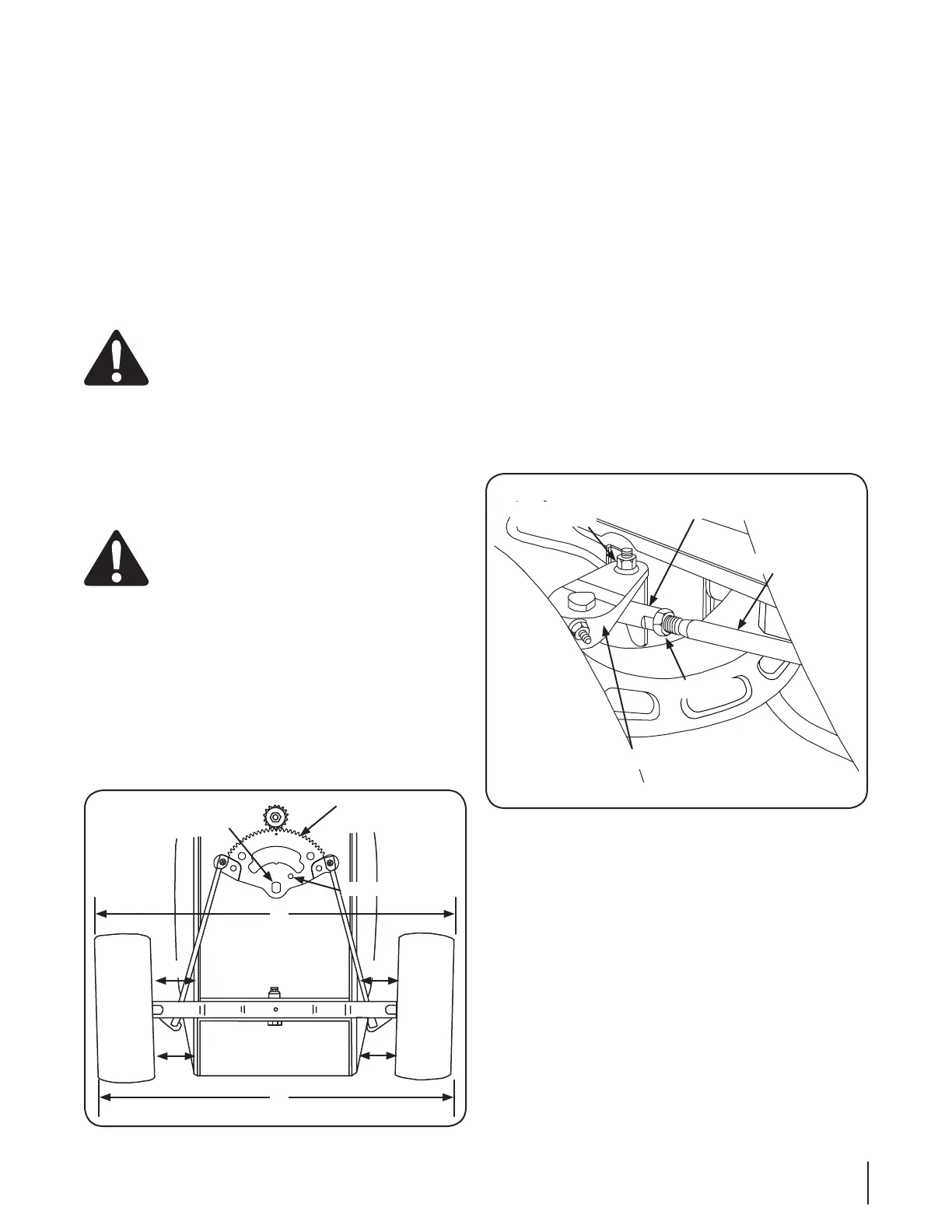

Wheel Alignment

The front wheels should toe-in approximately ⁄ to ⁄, as

Steering/Toe-in Adjustment

To adjust front wheel toe-in, proceed as follows:

Check the steering gear to ensure it is in the centered

position. The hole in the steering segment gear will align

NOTE: A ⁄

assure the steering segment is centered.

Mark the front horizontal diameter of both front wheels at 2.

the same spot on each wheel-preferably the inner bead

flange of the wheel rims. Mark the rear horizontal diameter

of both front wheels in the same manner.

Measure the distance between the bottom edges of the

tractor frame channels and the marks on the front of

measurements should be equal.

Measure the distance between the frame and the marks 4.

6-8). Measurement D should be approximately ⁄- to ⁄-

inch less than measurement C on each side of the tractor.

5.

Disconnect the front ball joints from the steering arms 6.

move each wheel to achieve the required toe-in and equal

D measurements.

Making sure not to move the steering gear or either wheel, 7.

turn the ball joint in or out on each drag linkas necessary to

align with the hole in each steering arm.

Reinstall the ball joints in the steering arms and secure with 8.

the hex lock nuts. Tighten the jam nuts against the ball

joints.

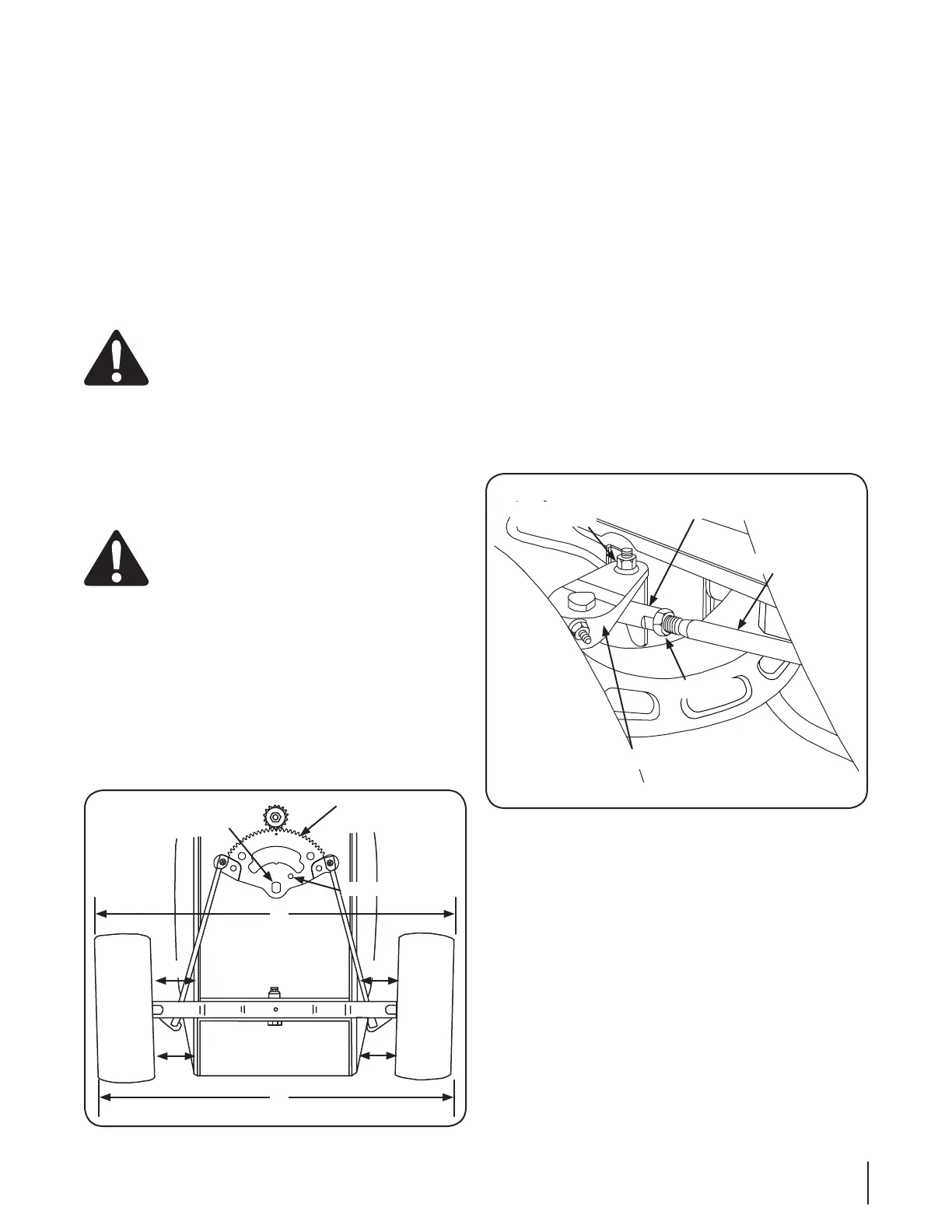

Figure 6-8

Centering Hole

Steering Gear

Centered

A

B

C C

D

D

Pivot Hole

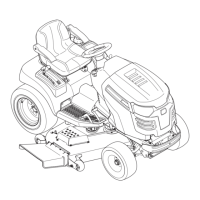

Ball Joint

Jam Nut

Drag Link

Steering Arm

Hex Lock Nut

Figure 6-9

Loading...

Loading...