14 Section 3 — controlS & operation

2. Move the ROPS into the desired position. The

three positions are TRANSPORT (a) position,

TRANSPORT WITH BAGGER (b) position and

into the OPERATION (c) position. See Figure 3-2.

3. Rotate both locking pins into the LOCKED

position. Move the upper ROPS slightly until

the locking pins are fully engaged in the

LOCKED position.

Accessory Switch Receptacles

The two receptacles (SD models) or one receptacle

(SDL models) for optional accessories are on the

RH console. See the Attachments & Accessories

section for information. The receptacle(s) are for

switches for an optional electric deck lift, lights

and/or an auxiliary switch.

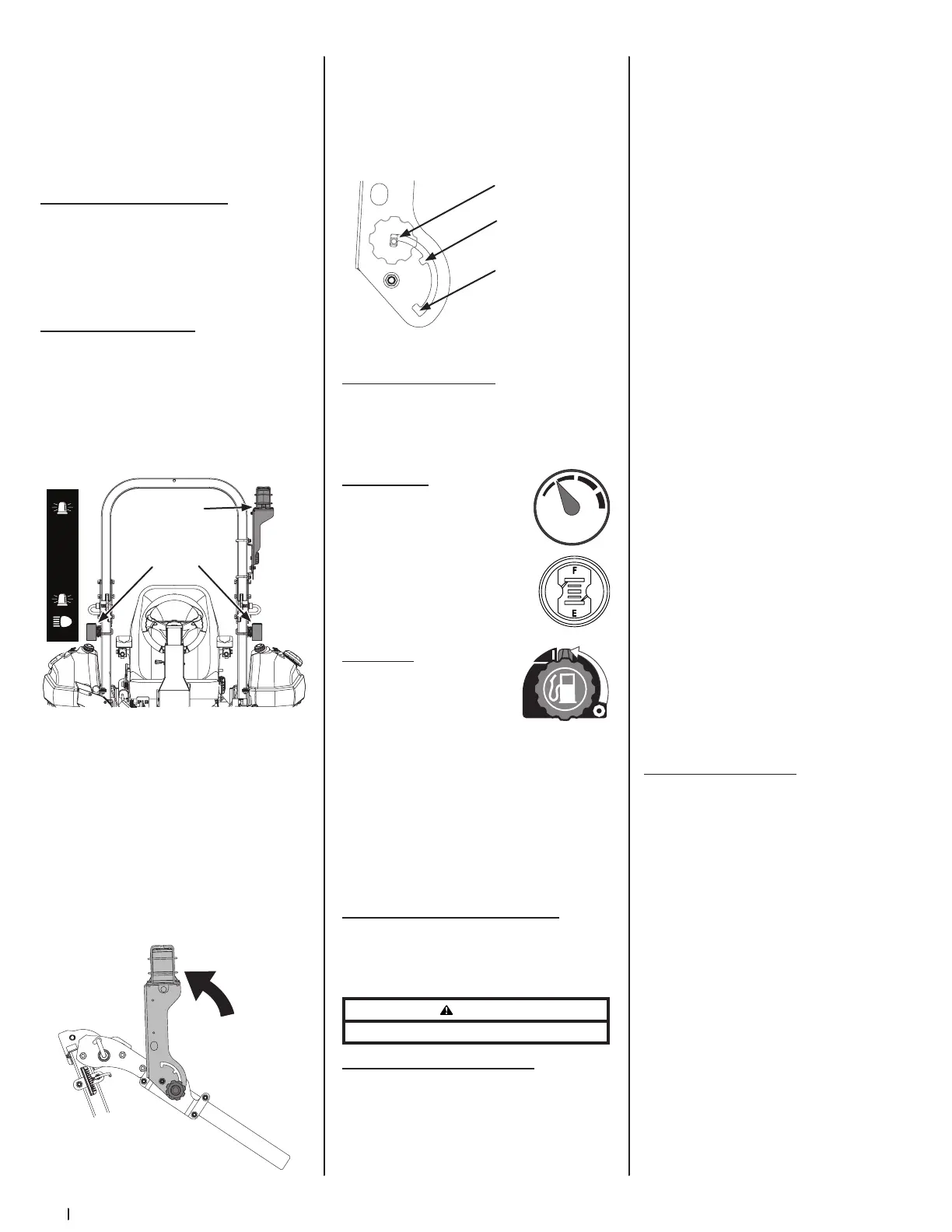

Work and Beacon Lights

Located in front of the two accessory switch

receptacles on the RH console, this three-way

switch toggles between:

• Lights OFF (center position)

• Beacon Light ON (right position)

• Beacon Light and Work Lights ON (left

position. See Figure 3-4.

LIGHTS

+

Work Lights

Beacon Light

Figure 3-4

Setting the Beacon Light

The Beacon Light should be positioned upright

at all times while operating the tractor. To set the

beacon light:

1. Set the ROPS to the desired position as

previously instructed.

2. Loosen the knob at the base of the beacon

light assembly and slide the assembly out of

the groove securing it in position.

3. Rotate the assembly to face the beacon light

straight upward. See Figure 3-5.

Figure 3-5

4. Slide the pertinent groove on the beacon

light assembly securely into place with the

knob, and tighten the knob.

Note: In Figure 3-5 the ROPS is shown in

Transport Position. Take note of the settings

used for the different beacon light positions.

See Figure 3-6.

Operation Position

Transport Position

Transport With Bagger

Position

Figure 3-6

12V Outlet (If Equipped)

The 12V outlet is located to the right of the

operator’s seat on the lower panel of he RH console

and is used for the convenience of plugging in

accessories that require a power source with a

maximum load of 5A at 12V.

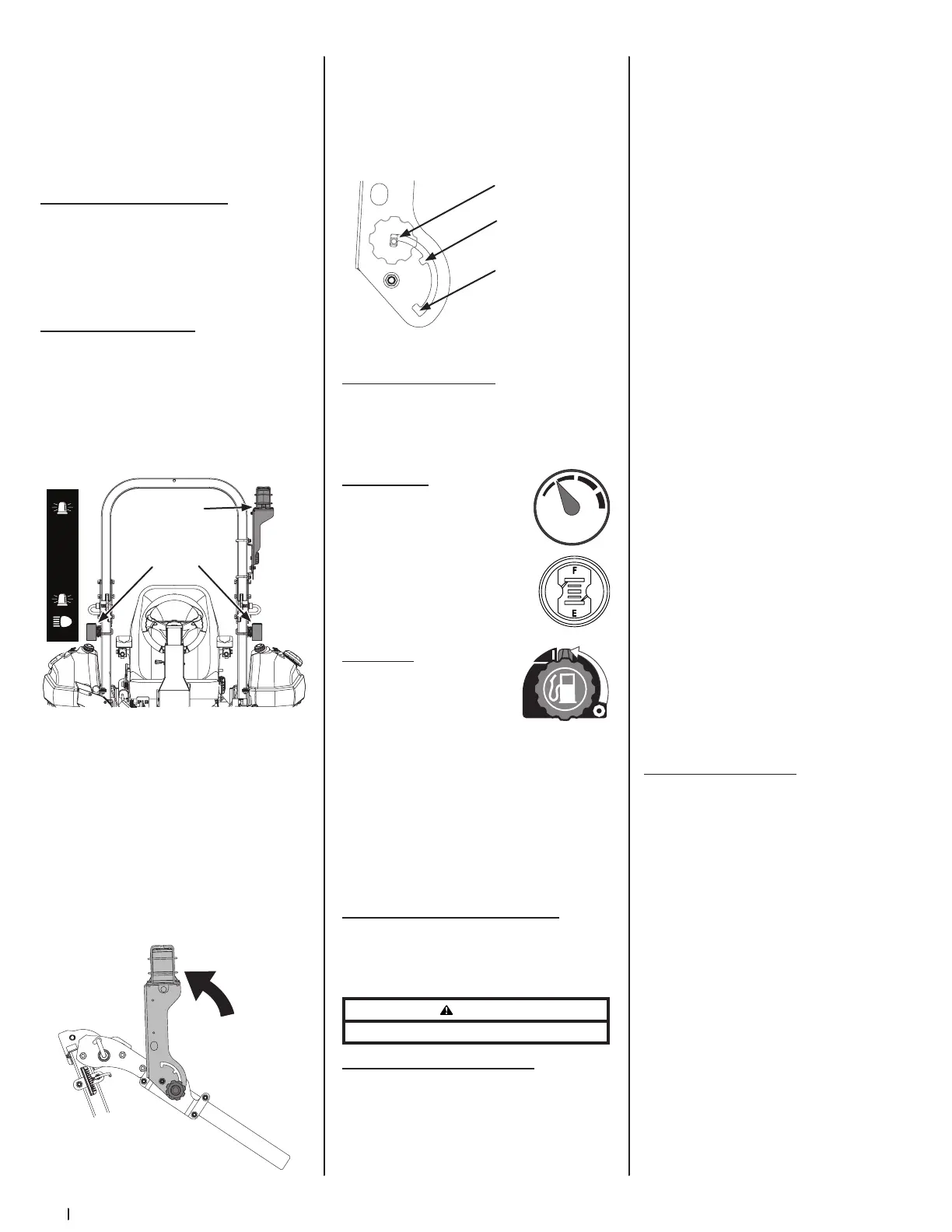

Fuel Gauge(s)

There is a fuel gauge on top of each

of the two fuel tanks or a single

gauge to the right of the operator’s

seat on the RH console. The gauges

measure the fuel level in each tank.

Fuel Valves

The fuel valves are located near

the rear of each fuel tank. The

valve controls the fuel flow from

the right and left tank and also

can shut off fuel flow to the engine. Rotate the

valve counterclockwise to open the flow from the

tank(s). Rotate the valve clockwise to stop the flow

from the tank(s). The fuel tanks can be operated

together, independently or shut the fuel flow off

completely.

Note: IF both tanks are on, and one is empty the

engine will not start. Be certain to make sure both

tanks have fuel or that the empty tank’s fuel valve

is closed.

Front Wheel Weights (Not Shown)

There are four 25-lb tire weights on the front of the

tractor for a total of 100-lbs. Two 25-lb weights on

each tire, one on the inside and one on the outside

of the front rims.

WARNING

Do not operate the tractor without the wheel weights in place.

Before Operating Your Tractor

1. Before you operate the tractor, study this

manual carefully to familiarize yourself with the

operation of all the instruments and controls.

It has been prepared to help you operate and

maintain your machine efficiently.

2. Fill the fuel tank with only clean, fresh,

unleaded gasoline with a pump sticker

octane rating of 87 or higher. When the

fuel reaches ⁄” below the bottom of the fill

neck, stop. DO NOT OVERFILL. Space must

be left for expansion.

3. Never use gasoline containing more than

10% ethanol or methanol.

4. Check the engine oil level as instructed in

the Engine Operator’s manual.

5. Check the transmission oil level. The

transmission oil expansion reservoir is

located beneath the operator’s seat. Always

wipe off the area around the reservoir fill

neck before checking the oil level to prevent

dirt from contaminating the oil. Remove the

cap and make sure the oil level is a ¼” above

the bottom of the reservoir. If the oil level is

low, fill with Castrol™ (Syntec®) Edge™.

6. Check the tire inflation pressures 10-12 psi

for the rear tires, 20-25 psi for the front tires.

Note: New tires are over-inflated in order to

properly seat the bead to the rim.

7. Check that all nuts, bolts and screws are tight.

8. Check the tension of the deck drive belts.

a. Remove the deck cover

b. The tension of the deck drive

belts are maintained by a spring

mechanism that adjusts for wear and

stretch.

c. Examine the belts for cuts, fraying,

and excessive wear. Replace if any of

these are detected.

d. Replace the deck cover.

9. Check if deck is level. When correctly

adjusted the mower deck should be level

side to side, and the front of the deck should

be approximately ⁄” lower than the rear of

deck. If deck needs to be leveled, refer to

the Service section.

10. Lubricate all pivot points listed in the

Service section.

11. Adjust the seat for operator’s maximum

comfort, visibility and for maintaining

complete control of the machine. Refer

to the Assembly & Set-Up section for

instructions on adjusting the seat.

Safety Interlock System

This machine is equipped with a safety interlock

system for the protection of the operator. If the

interlock system should ever malfunction, do not

operate the machine. Contact your authorized

service dealer.

• The safety interlock system prevents the

engine from cranking or starting unless

the speed control pedals are in the neutral

position, the parking brake is engaged, and

the PTO knob is disengaged.

• To avoid sudden movement when

disengaging the parking brake, the safety

interlock system will shut off the engine if the

speed control pedals are moved to a position

other than the neutral position when the

parking brake is engaged.

• The safety interlock system will shut off the

engine if the operator leaves the seat before

engaging the parking brake.

• The safety interlock system will shut off

the engine if the operator leaves the seat

with the PTO knob engaged, regardless of

whether the parking brake is engaged.

Note: The PTO knob must be in the

disengaged position to restart the engine.

Loading...

Loading...