Se rvi ce

7

34

Battery Removal

WARNING! Battery posts, terminals and related

accessories contain lead and lead compounds. Wash

hands after handling.

The battery is located beneath the seat box frame. To remove the

battery:

1. Remove the hold down strap.

2. Remove the hex screw and flange lock nut securing the

black negative battery lead to the negative battery post

(marked NEG). Move the cable away from the negative

battery post.

3. Remove the hex screw and flange lock nut securing the red

positive battery lead to the positive battery post (marked POS).

4. Carefully lift the battery out of the tractor.

5. Install the battery by repeating the above steps in the

reverse order.

WARNING! Always connect the positive lead to

the battery before connecting the negative lead.

This will prevent sparking or possible injury from an

electrical short caused by contacting the tractor

body with tools being used to connect the cables.

Charging the Battery

Test and, if necessary, recharge the battery after the tractor has

been stored for a period of time.

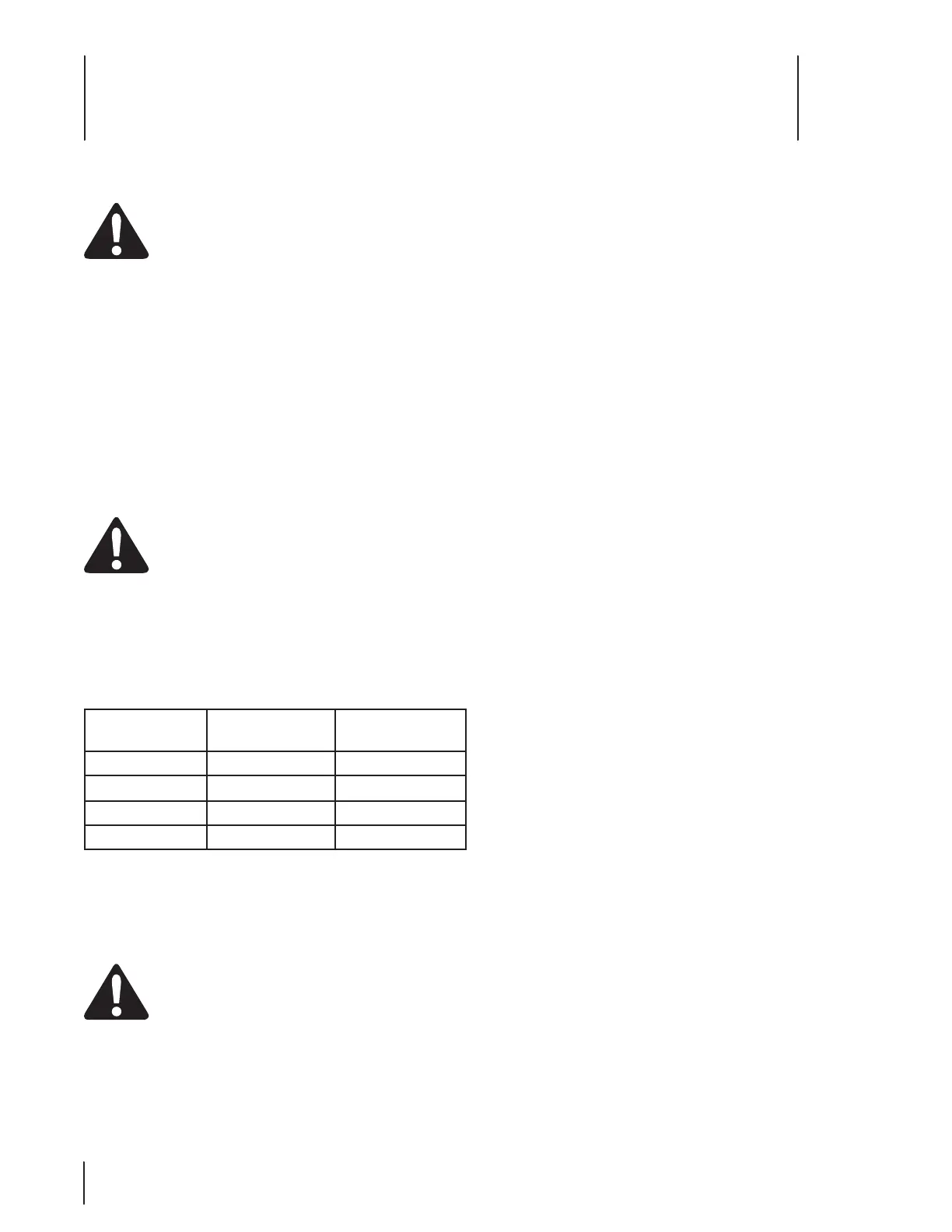

• A voltmeter or load tester should read 12.6 volts (DC) or

higher across the battery terminals. See Figure 7-1.

Figure 7-1

• Charge the battery with a 12-volt battery charger at a

MAXIMUM rate of 10 amps.

Jump Starting

WARNING!: Failure to use this starting procedure

can cause sparking, and the gases in the battery to

explode.

1. Connect the end of one cable to the disabled machine

battery’s positive terminal; then connect the other end of

that cable to the booster battery’s positive terminal.

2. Connect one end of the other cable to the booster

battery’s negative terminal; then connect the other end of

that cable to the frame of the disabled tractor, as far from

the battery as possible.

Voltmeter

Reading

State of

Charge

Charging

Time

12.7 100% Full Charge

12.4 75% 90 Min.

12.2 50% 180 Min.

12.0 25% 280 Min.

3. Start the disabled tractor following the normal starting

instructions previously provided; then disconnect the

jumper cables in the exact reverse order of their connection.

4. Have the tractor’s electrical system checked and repaired

as soon as possible to eliminate the need for jump starting.

Servicing Electrical System

Fuse

There is a fuse located inside the left console. Lift the seat and

look down at the left console to find the location of the fuse. A

25 amp for fuse the ignition, PTO, etc. This is a standard plug-in

type automotive fuse. Always use the same capacity fuse for

replacement. Check the fuse for all electrical problems.

If you have a recurring problem with blown fuses, have the tractor’s

electrical system checked by your Cub Cadet Service Dealer.

Safety Switch Operation Checks

The following operational checks should be made daily:

PTO Switch

1. Sit in the operator’s seat. With the drive levers are in the

neutral position and the parking brake engaged, engage

the PTO switch by pulling up on the knob and try to start

the engine. The engine should not start. If it does, the PTO

switch must be replaced. See an authorized service dealer.

2. If the engine does not start, disengage the PTO by pressing

the knob down and start the engine. Now enagage the PTO

and the blades should rotate.

3. If the blades do not turn, the PTO switch must be replaced,

the seat switch must be replaced or the electric PTO clutch

must be repaired. See an authorized service dealer.

Parking Brake Switch

• Sit in the operator’s seat. With the drive levers in the neutral

position and the PTO disengaged, release the parking brake

and try to start the engine. The engine should not start.

• If it does, the parking brake switch must be repositioned or

replaced. See an authorized service dealer. If the engine does

not start, engage the parking brake and start the engine.

Seat Switch

• With the drive levers in the neutral position, the parking

brake engaged and the PTO disengaged, start the engine.

Now release the parking brake, and raise up off the seat.

The engine should stop. If the engine does not stop, the

seat switch must be replaced. See an authorized service

dealer.

• With the drive levers in the neutral position, the parking

brake engaged and the PTO disengaged, sit in the operator’s

seat and start the engine. Enagage the PTO and the blades

should start to rotate. Raise up slightly off the operator’s seat

and the blades should stop. If the blades do not stop when

you dismount from the operator’s seat, the seat switch must

be replaced. See an authorized service dealer.

Loading...

Loading...