Section 5 — operation 21

7. Turn the ignition key clockwise to the START position

and release it as soon as the engine starts; however, do not

crank the engine continuously for more than 10 seconds

at a time. If the engine does not start within this time, turn

the key to STOP and wait at least 30 seconds to allow

the engine’s starter motor to cool. Try again after waiting.

If after a few attempts the engine fails to start, do not keep

trying to start it with the choke closed as this will cause

flooding and make starting more difficult.

8. Once the engine starts, push the choke halfway down and

as the engine warms, push the choke all the way down.

Cold Weather Starting

When starting the engine at temperatures near or below freezing,

ensure the correct viscosity motor oil is used in the engine and the

battery is fully charged. Start the engine as follows:

1. Be sure the battery is in good condition. A warm battery

has much more starting capacity than a cold battery.

2. Use fresh winter grade fuel. Winter grade gasoline has

higher volatility to improve starting. Do not use gasoline

left over from summer.

3. Follow the previous instruction for Starting the Engine.

Using Jumper Cables To Start Engine

WARNING! Batteries contain sulfuric acid and

produce explosive gasses. Make certain the area is

well ventilated, wear gloves and eye protection, and

avoid sparks or flames near the battery.

If the battery charge is not sufficient to crank the engine,

recharge the battery. If a battery charger is unavailable and

the tractor must be started, the aid of a booster battery will be

necessary. Connect the booster battery as follows:

1. Connect the end of one cable to the disabled machine

battery’s positive terminal; then connect the other end of

that cable to the booster battery’s positive terminal.

2. Connect one end of the other cable to the booster

battery’s negative terminal; then connect the other end of

that cable to the frame of the disabled tractor, as far from

the battery as possible.

3. Start the disabled tractor following the normal starting

instructions previously provided; then disconnect the

jumper cables in the exact reverse order of their connection.

4. Have the tractor’s electrical system checked and repaired

as soon as possible to eliminate the need for jump starting.

Stopping the Engine

1. Disengage the PTO.

2. Move the RH and LH drive control levers fully outward in

the neutral position.

3. Engage the parking brake.

4. Move the throttle control to midway between the SLOW

and FAST positions.

5. Turn the ignition key to the STOP position and remove

the key from the ignition switch.

NOTE: Always remove the key from the ignition switch

to prevent accidental starting or battery discharge if the

equipment is left unattended.

Practice Operation (Initial Use)

Operating a zero-turn tractor is not like operating a conventional

type riding tractor. Although and because a zero turn tractor is

more maneuverable, getting used to operating the control levers

takes some practice.

We strongly recommend that you locate a reasonably large,

level and open “practice area” where there are no obstructions,

pedestrians, or animals. You should practice operating the

tractor for a minimum of 30 minutes.

Carefully move (or have moved) the tractor to the practice area.

When performing the practice session, the PTO should not be

engaged. While practicing, operate the tractor at approximately ⁄-

⁄ throttle and at less than full speed in both forward and reverse.

Always wear appropriate clothing and personal protection

equipment (e.g. safety glasses, long pants, gloves, hearing

protection, safety shoes, hard hat) when operating or

maintaining this machine. Follow all federal, state and local

guidelines regarding the use of personal protective equipment.

Carefully practice maneuvering the machine using the instructions

in the following section “Driving the Tractor.” Practice until you are

confident that you can safely operate the tractor.

Driving the Tractor

1. Ensure that the area is free of animals and bystanders,

especially children!

2. Survey the area where the equipment is to be used to make

sure it is free of debris, sticks, stones, wires, bones, and other

foreign objects which could cause injury to bystanders,

damage to the machine, or damage to nearby facilities.

WARNING! Avoid sudden starts, excessive speed

and sudden stops.

3. Adjust the operator’s seat to the most comfortable

position that allows you to operate the controls. See seat

adjustment in the Assembly & Set-Up section.

4. Release the parking brake.

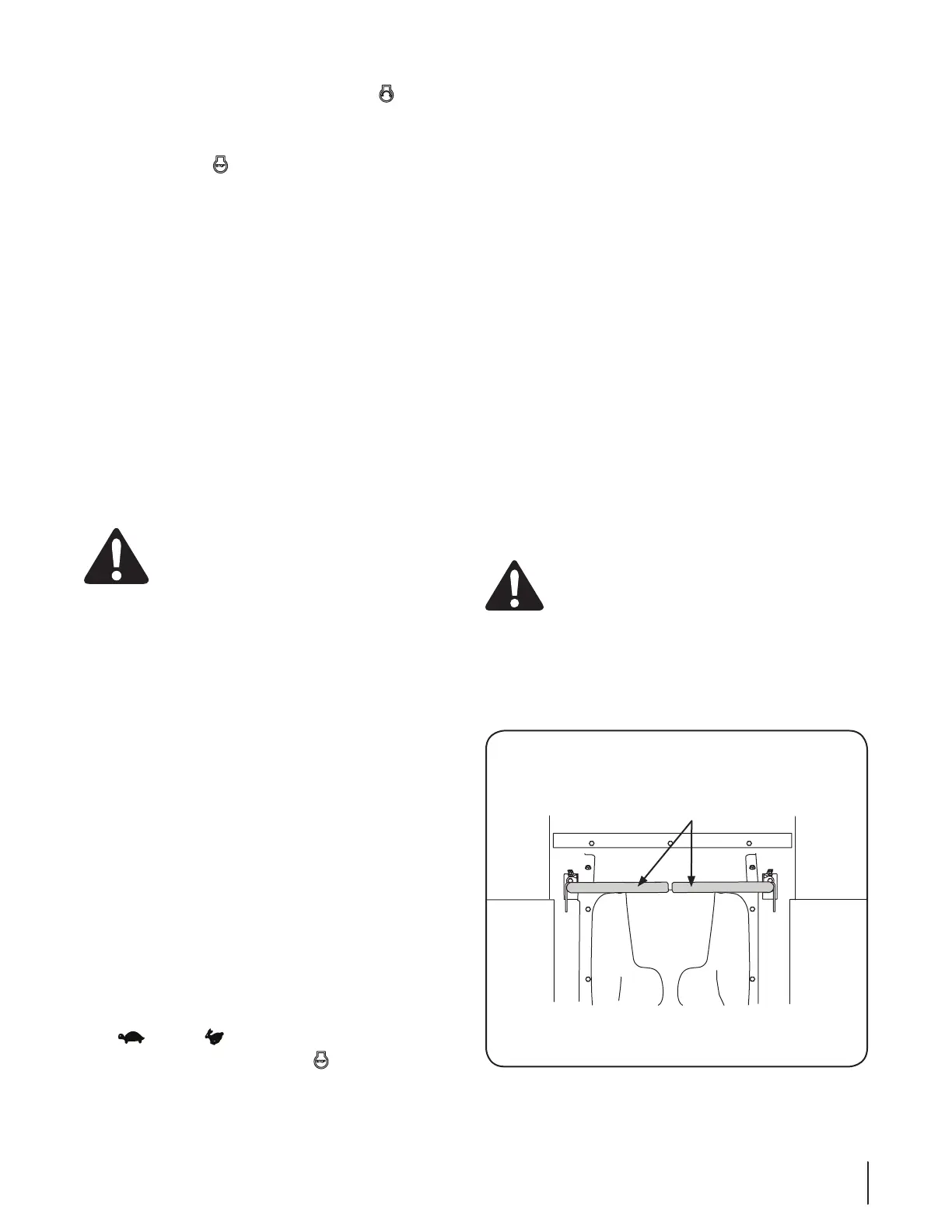

5. Move the RH and LH drive control levers inward in the

neutral position. Refer to Figure 5-1.

Control Lever Moved

Inward and in Neutral

Figure 5-1

NOTE: If the control levers are not even in the neutral

position, refer to Assembly & Set-Up for instructions to

adjust the levers so that they are even.

Loading...

Loading...