Section 7 — Service 37

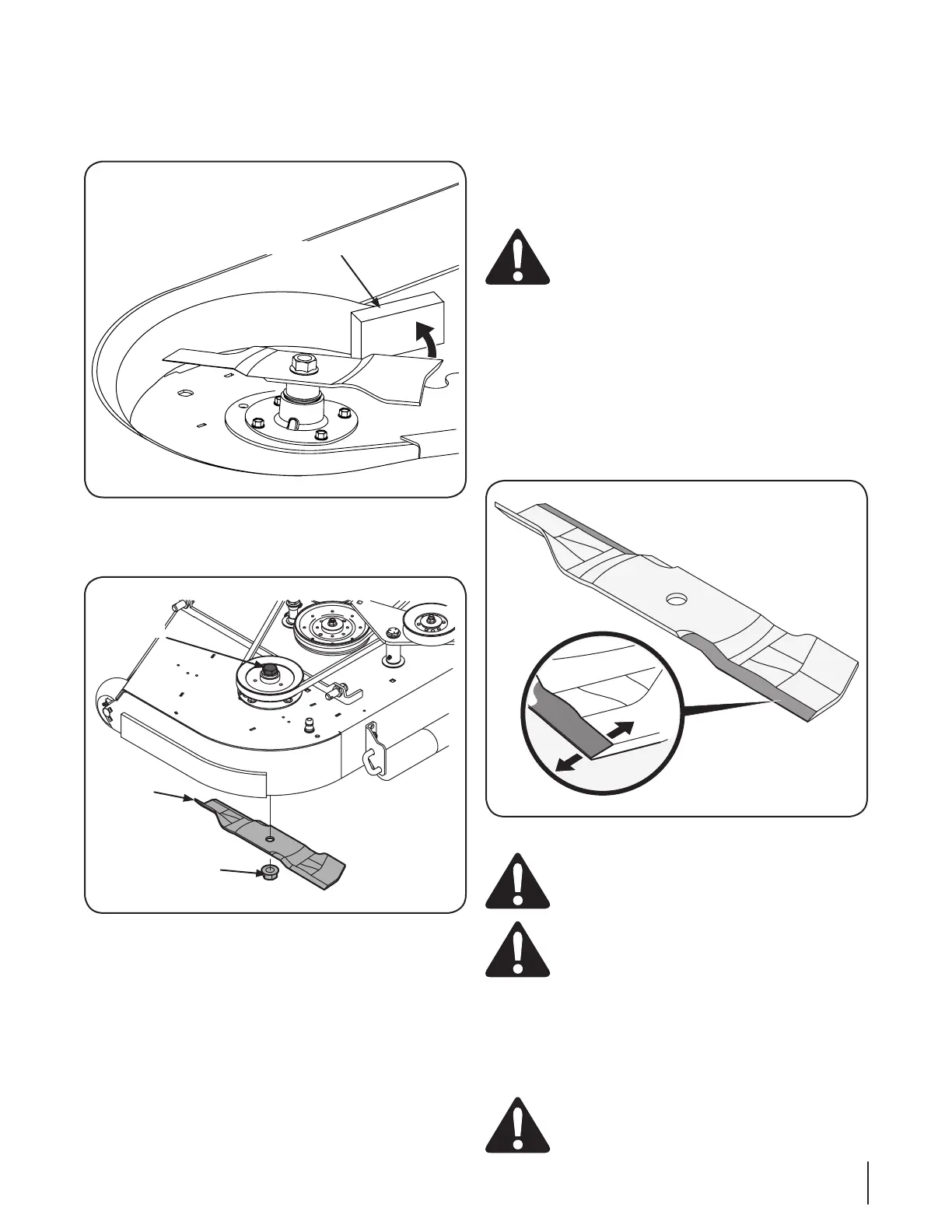

3. Wrap a rag around one end of the blade and grasp it to

prevent it from turning, or secure the blade by placing a

block of wood between the blade and the deck housing.

See Figure 7-8.

Figure 7-8

4. Use a 1-⁄” socket wrench on the pulley side of the spindle

bolt. See Figure 7-9.

Flange Lock Nut

Blade

Hex Screw

Figure 7-9

5. Remove the hex nut at the blade using a 1-⁄” wrench and

remove the blade.

6. To replace the blade reverse the above process and tighten

nut to 100-120 lb ft.

NOTE: When replacing the blade, be sure to install the

blade with the side of the blade marked ‘‘Bottom’’ or “Grass

Side” (or with a part number stamped in it) facing the

ground when the mower is in the operating position.

NOTE: Add a small amount of multi-purpose grease to the

bolt threads to avoid corrosion and galvanic action.

WARNING! Never mow with dull blades. Blades that

are bent should be replaced. The cutting blades are

sharp and can cause severe injury. Wrap the cutting

surface of the blade with a rag to avoid injury.

Sharpening the Blades

1. Set the parking brake.

2. Clean any debris from the blades. Keep blades sharp and

free of build up at all times.

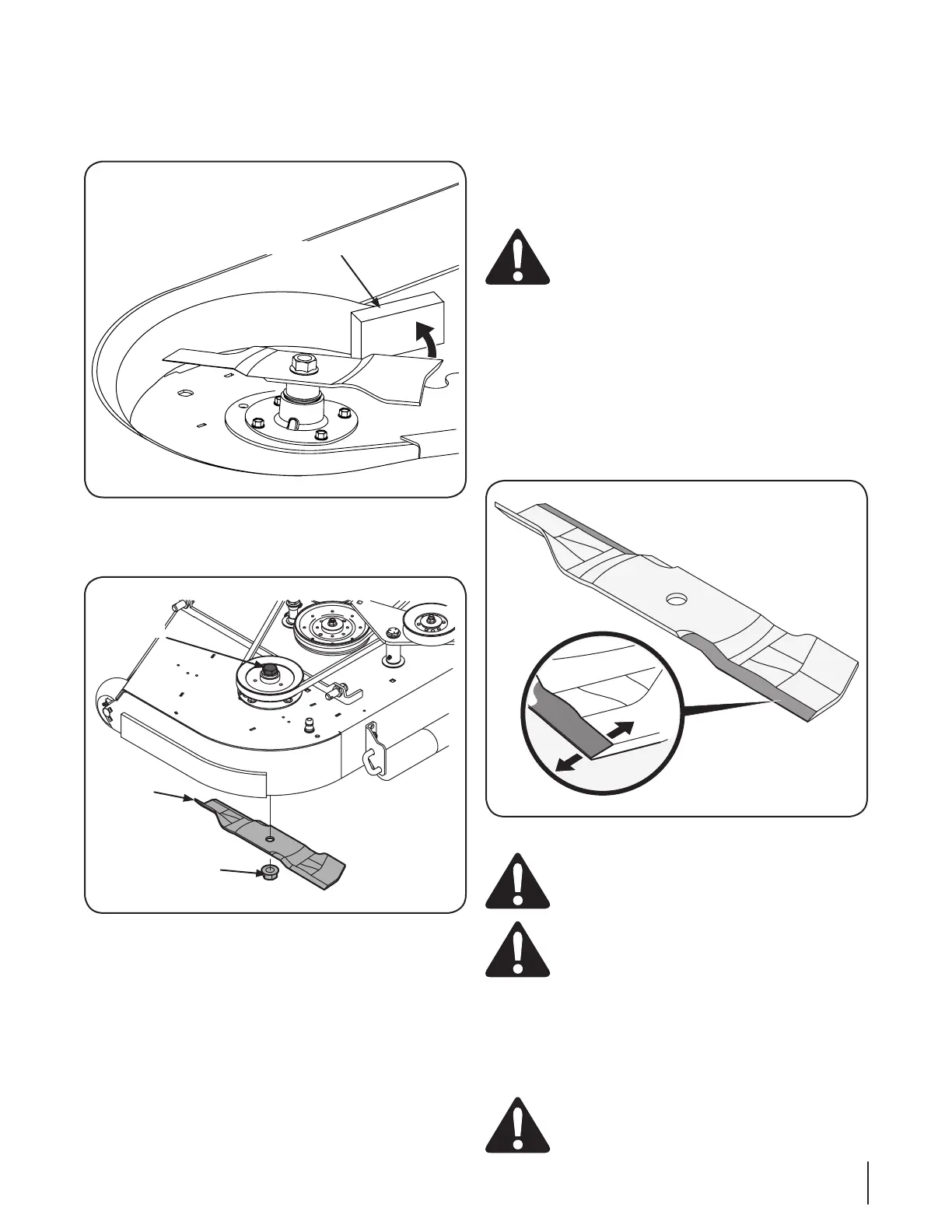

3. To properly sharpen the cutting blades, remove equal

amounts of metal from both ends of the blades along the

cutting edges, parallel to the trailing edge, at a 25°-30°

angle. Always grind each cutting blade edge equally to

maintain proper blade balance. See Figure 7-10.

Figure 7-10

WARNING! If a blade is bent or otherwise

damaged, replace the blade with a new one. Use

only original equipment blades.

WARNING! A poorly balanced blade will cause

excessive vibration, may damage the machine and/

or result in personal injury.

4. Test the blade’s balance using a blade balancer. Grind

metal from the heavy side until it balances evenly.

NOTE: When replacing the blade, be sure to install the

blade with the side of the blade marked ‘‘Bottom’’ or “Grass

Side” (or with a part number stamped in it) facing the

ground when the mower is in the operating position.

WARNING! Use a torque wrench to tighten the

blade spindle hex flange nut to between 100 lbs-ft

and 120 lbs-ft.

Loading...

Loading...