6

INSTALLATION PROCEDURE

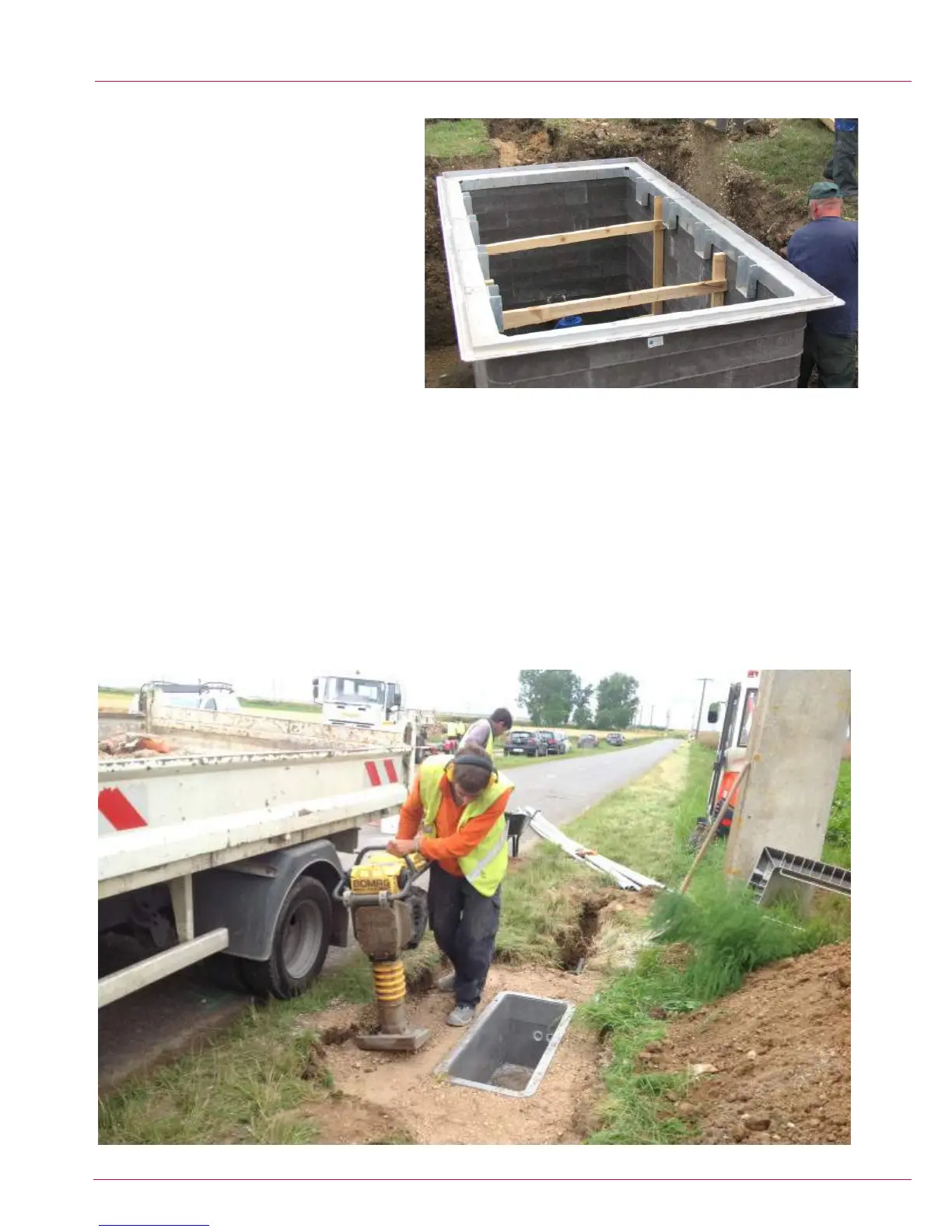

Bracing

10. On certain chambers cross bracing is required. See

Table 1 for details.

10.1. If timber bracing is required this should be

supplied with the chamber. Make sure that the bracing

is vertical and plumb and located in the correct position.

10.2. On larger chambers “Acrow” props are used as

bracing.

These are not supplied by CUBIS. Timber footplates

should be used to disperse the loads evenly over the

chamber. See Table 1 for spacing details.

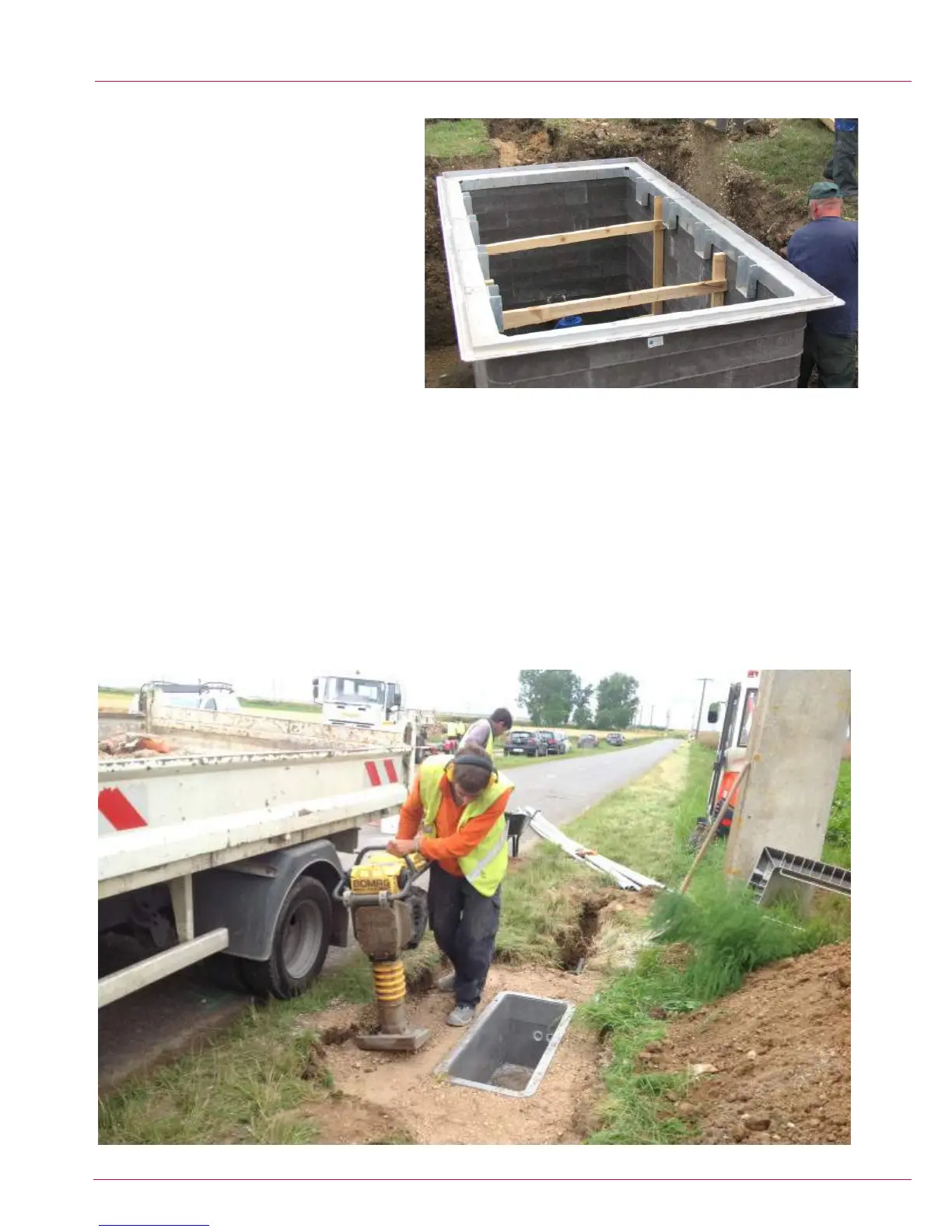

Backlling

11. With the chamber installed to its nished depth, duct entries formed, furniture tted and if required suitable bracing installed, the backll

surround of the chamber can now take place. Backlling is formed in layers and should be completed to the top of the chamber, or in the

case of a roadway construction to the underside of the blacktop construction. Refer to Table 1 for the recommended backll material and

required width of material.

Refer to “Specication for the Reinstatement of Openings in Highways - Appendix A8” for the depth of layers and number of

passes required for the selected material and compaction method.

11.1. If timber bracing is being used, this should be raised along with the backlling to ensure that there is adequate support for the chamber

wall section that is being compacted against.

11.2. If Acrow props are required these can be left in position until the backll and compaction are completed and the material has adequately

cured.

Loading...

Loading...