ENGLISH

TABLE

OF

CONTENTS

Technical

data

Attention!

General

remarks

Machine

description

Preparation

Mounting

and

filling

the

bottle

Control

of

moistening

and

water

level

Loading

of the

tape roll

Operating

instructions

Maintenance

and

care

TECHNICAL

DATA

MAIN FEATURES

Dimensions

of

machine:

45x29x25

cm.

approx.

Weight

of

machine:

13

Kgs. approx.

Voltage

and

frequency:

see

machine label

Control

circuit

in DC 24

Volts

Electrical power:

100 W

Dispensing

velocity: 55m./min.

Length:

min.

100

mm./

max. 1150

mm.

Sound

level measured

in

room: less than

70

dB(A)

TYPES

OF

GUMMED

TAPE

All

PAPER

FEATURES

Width:

min.

20

mm./

max.

100 mm.

Maximum

roll diameter:

200

mm.;

with device

for

bigger rolls

(supplied

on

request)

300 mm.

ATTENTION!!

-

Before

using this machine carefully

read

the

operating instructions. They

contain

important indications

on

instal-

lation

safety,

use and

maintenance.

-

Keep this booklet with care

for any

further

reference.

It's

customer

responsibility

to

make

sure that

the

personnel

who

will

use

the

machines reads

and

understands this

booklet.

-

The

builder cannot

be

made responsible

for

eventual damage

to

people, animals

or

things deriving from

non

observation

of the

safety

norms

and the

warnings here

contained.

GENERAL REMARKS

-

Follow

the

safety

and

prevention rules

for

accidents

and

fires

issued

by the

competent authorities, such

as the

eventual recommendations

of

industrial

associations

and

trade unions

in

terms

of

personnel safety.

-

This tape dispenser

is

designed

and

manufactured

only

to

dispense gummed

tape.

A

different

use

from

that

advised

is

not

considered specific. CYKLOP will

not

assume

any

responsibility following

an

improper

use of the

machine.

-

After

unpacking check

the

integrity

of the

machine.

In

case

of

doubt

do not use the

machine

and

enquire

directly

to the

reseller.

-

Verify

that

the

voltage

of the

machine

is

the

same

as the one you are

about

to

use.

Otherwise

do not use the

machine

and

enquire directly

to the

reseller.

-

The

electrical safety

of

this machine

is

guar-

anteed only when

it is

correctly connected

to

a

grounded electrical system

as

prescribed

by

the

present electrical safety rules.

-

When

you

disconnect

the

machine from

the

electrical plug, always pull

by

seizing

the

plug

not the

cable.

-

Never touch

or

operate

the

machine with

wet

hands

or

barefoot.

-

Do not

leave

the

machine

on for

long

periods

of

time. Turn

off the

main switch

of

the

machine when

it is not

being

used.

-

Keep

the

machine away from children

and

from

personnel

who are not

authorised

or

adequately

instructed

in the use of it.

-

The use of the

machine,

as

prescribed

by

the

builder, also includes

the

respect

of the

rules

of

inspection,

maintenance

and

repair.

-

Some parts

of the

machine reach

dangerous temperatures

and

therefore they

should NEVER

be

touched with

the

hands.

The top

heater,

if

functioning,

can

reach

a

high temperature (100°C).

-

Keep

the

machine always

in

good

status,

clean

and

dry.

-

The

machine performs better

in a

rather

dry

environment, therefore

we

discourage

usage

in

damp places. Working with

gummed paper

in

humid places

can

create

problems;

it

performs

better

in dry

places.

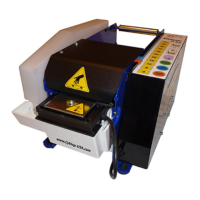

MACHINE DESCRIPTION

ASSEMBLY

(Fig.

1)

A

Main

cable

and

plug

B

Side cover

C

Main light switch

D

Switch-board

L Top

Heater

M

Water tank

I Top

heater switch

N

Water bottle

•

OPERATING ELEMENTS

E

Green

pushbutton

'free

length'

- it

dispenses tape continuously until

released.

F

Pushbuttons

for

dispensing

11

pre-set

lengths

of

tape

G +5

pushbutton:

it

increases pre-set

lengths

by 5 cm.

H

'SHORT

LENGTH'

sets

one

short length

of

tape

-

'LONG

LENGTH'

sets

one

length

of

tape longer than

the

first

one

Q

Colored indicators.

PREPARATION

Brush.

-

Before using

a new

dispenser, wash

the

moistening brush with water

and

soap.

Rinse

it

with water.

-

After

inserting

the

brush

in the

water tank,

proceed

to

mounting

the

water tank itself

following

the

operations

below.

Switching

the

machine

on.

-

Insert main plug into proper outlet

and

switch

the

machine

on.

Loading

of

water tank (Fig.

2).

-

With

the

right hand keep

the

green button

pressed.

-

Take

the

water

tank

with

the

left hand

and

insert

the

pivot

in the

proper seats

as

indicated

by the

arrow.

-

Turn

the

water

tank

following

the

arrow

direction

on

picture

2

till

it

touches

the

back

part

of the

machine.

-

Lower

the

water tank

till

it

locks into

position. Release green button.

-

To

remove

the

water tank keep

the

green

button pressed with

the

right hand

and

lift

it

with

the

left

one

and,

by

rotating

it

remove

it

from

its

seat.

Mounting

of top

heater.

-

Place

the top

heater

(L) in the

water tank,

above

the

moistening

brush,

in its

proper

housing.

MOUNTING

AND

FILLING

THE

BOTTLE

(Fig.

3 and 4)

-

Mount

the

bottle holders (black plastic

U-shaped parts)

on the

left side

of the

machine, inserting

at

first

the

upper tooth

in

its

housing

and

then

the

lower

one

until

it

locks into position

as

shown

in

fig.

3.

-

Fill

the

bottle through

the

hole with clean

water.

Put a

finger

on the

hole

and

place

the

bottle

in its

housing with hole

on the

tank.

SUGGESTION:

the

machine works with

drinkable water.

Do not use

water with

carbonates;

for

safeguarding some parts

we

suggest demineralised water.

In

case drops

of

water fall

on the

machine

immediately wipe

it

dry.

CONTROL

OF

MOISTENING

AND

WATER

LEVEL (Fig.

4)

-

Before removing

the

bottle, make sure

that

it

does

not

contain

water, otherwise

Loading...

Loading...