ENGLISH

21

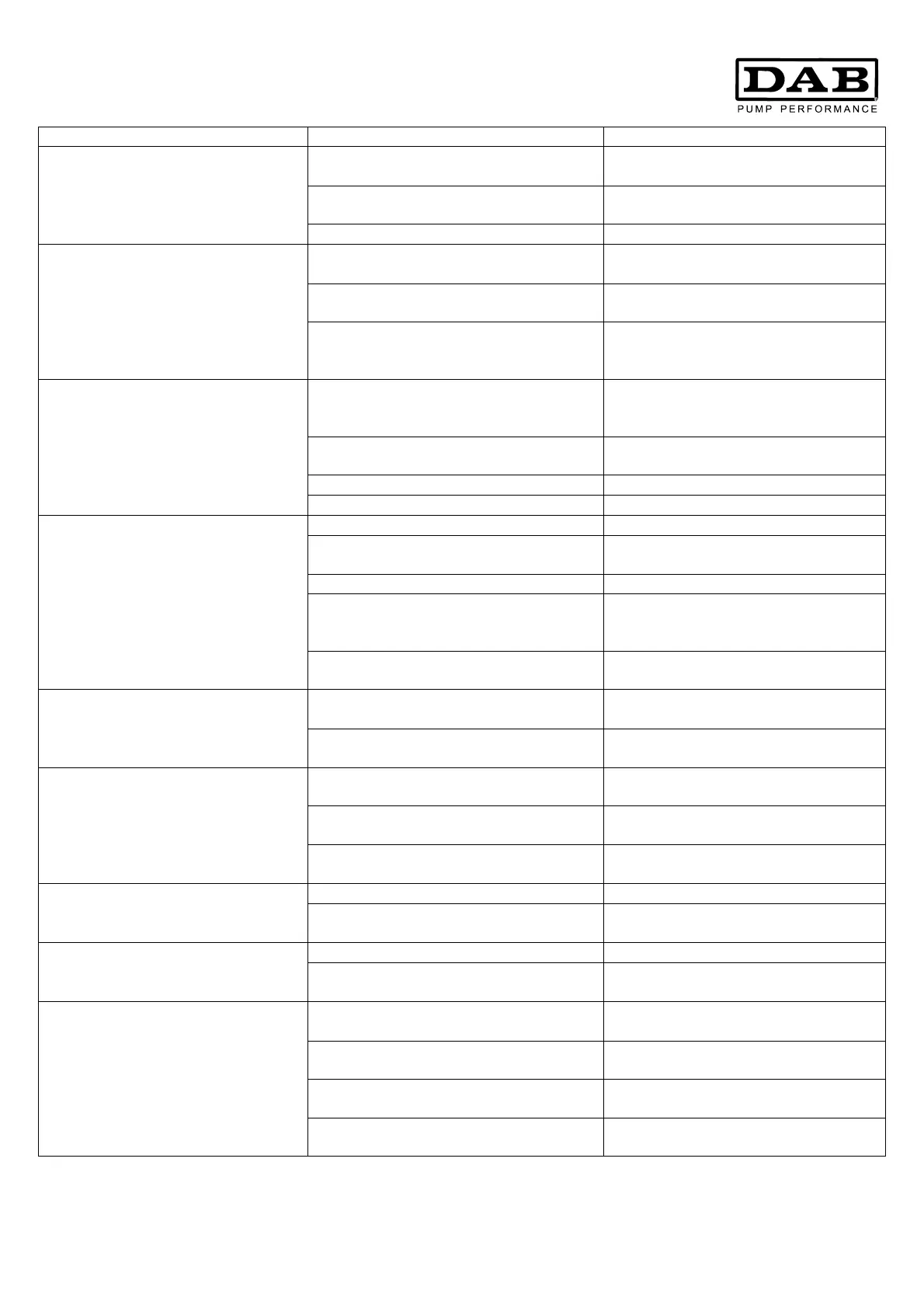

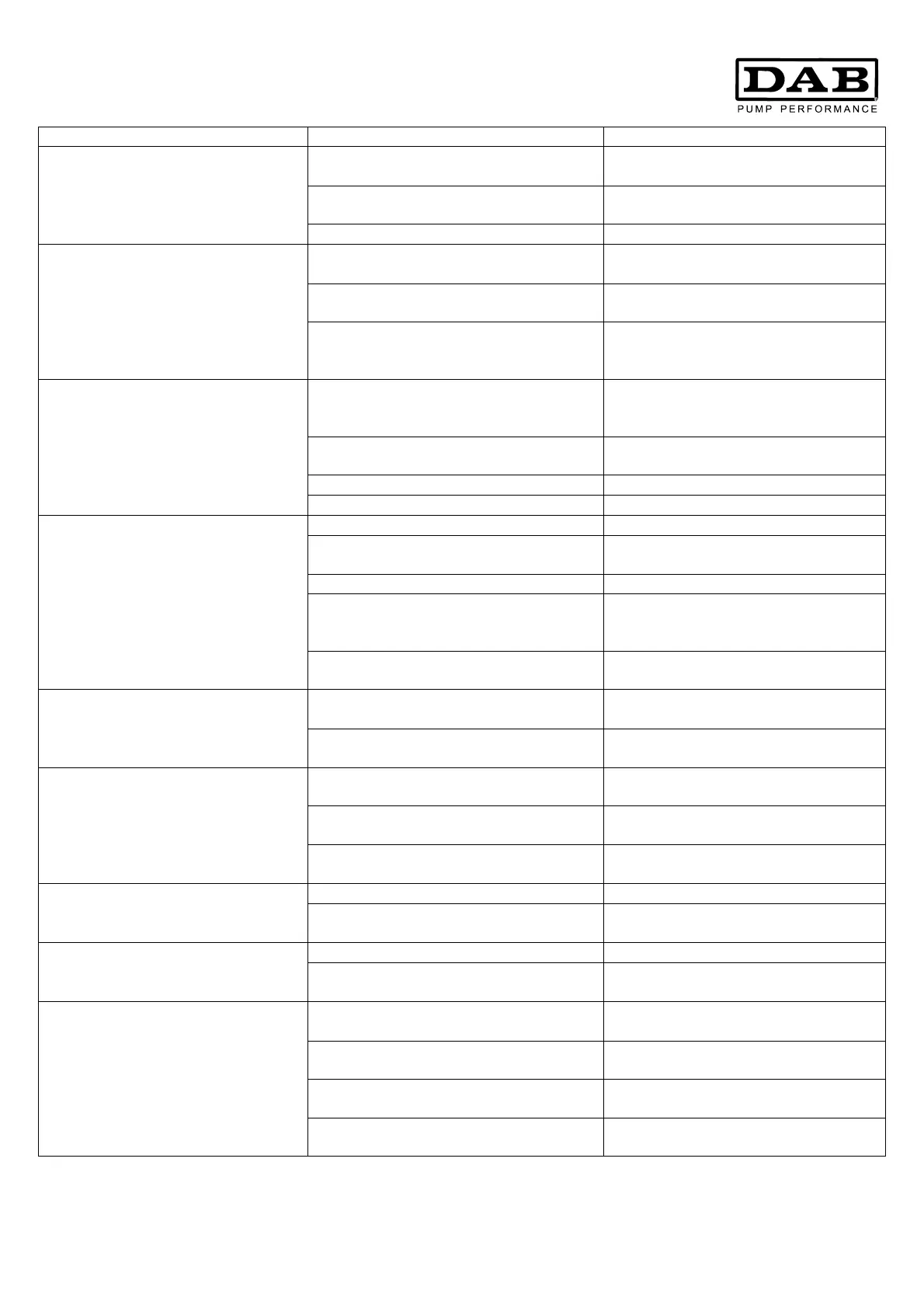

Fault Check (possible cause) Remedy

− Verify that supply voltage is at an

acceptable valve.

− Check whether any moving parts

are scraping against fixed parts.

Eliminate the cause of the scraping.

The motor turns with difficulty.

− Check the state of the bearings.

Change any worn bearings.

− Check that all the phases are

present.

Restore the missing phase.

− Look for possible open or dirty

contacts in the protection.

Change or clean the component

concerned.

The (external) motor protection

trips immediately after starting.

− Look for possible faulty insulation

of the motor, checking the phase

resistance and insulation to earth.

Change the motor casing with the

stator or reset any cables

discharging to earth.

− Ensure that the environment

temperature is not too high.

Provide suitable ventilation in the

environment where the pump is

installed.

− Check the calibration of the

protection.

Calibrate at a current value suitable

for the motor absorption at full load.

− Check the state of the bearings.

Change any worn bearings.

The motor protection trips too

frequently.

− Check the motor rotation speed.

− Check priming.

− On three-phase motors, check that

the direction of rotation is correct.

Invert the connection of two supply

wires.

− Difference in suction level too high.

− The diameter of the intake pipe is

insufficient or the horizontal stretch

is too long.

Replace the intake pipe with one

with a larger diameter.

The pump does not deliver.

− Foot valve or intake pipe blocked.

Clean the foot valve and the intake

pipe.

− The intake pipe or the foot valve is

taking in air.

Check the suction pipe, repeat the

priming operations.

The pump does not prime.

− Check the slope of the suction

pipe.

Correct the inclination of the intake

pipe.

− Foot valve or impeller blocked.

Remove clog. Replace the impeller

if weared down.

− The diameter of the intake pipe is

insufficient.

Replace the pipe with one with a

larger diameter.

The pump supplies insufficient flow.

− Check that the direction of rotation

is correct.

Invert the connection of two supply

wires.

− Intake pressure too low.

The pump flow rate is not constant.

− Intake pipe or pump partly blocked

by impurities.

Remove clog.

− Leakage in the intake pipe.

The pump turns in the opposite

direction when switching off.

− Foot valve or check valve faulty or

blocked in partly open position.

Repair or replace the faulty valve.

− Check that the pump and/or the

pipes are firmly anchored.

− There is cavitation in the pump.

Reduce the intake height or check

for load losses.

− The pump is running above its

plate characteristics.

Reduce the flow rate.

The pump vibrates and operates

noisily.

− The pump is not turning freely.

Check the state of wear of the

bearings.

Loading...

Loading...