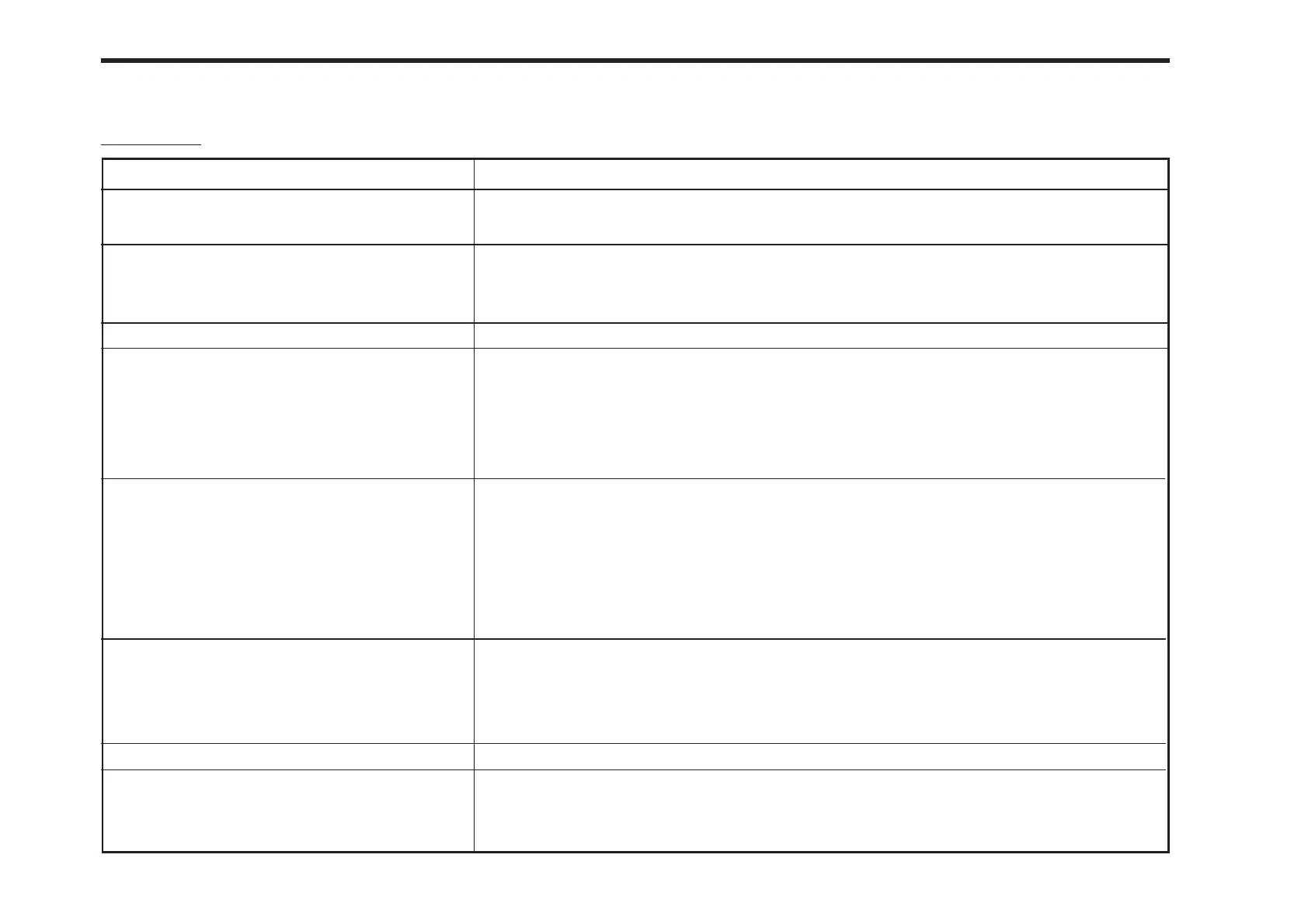

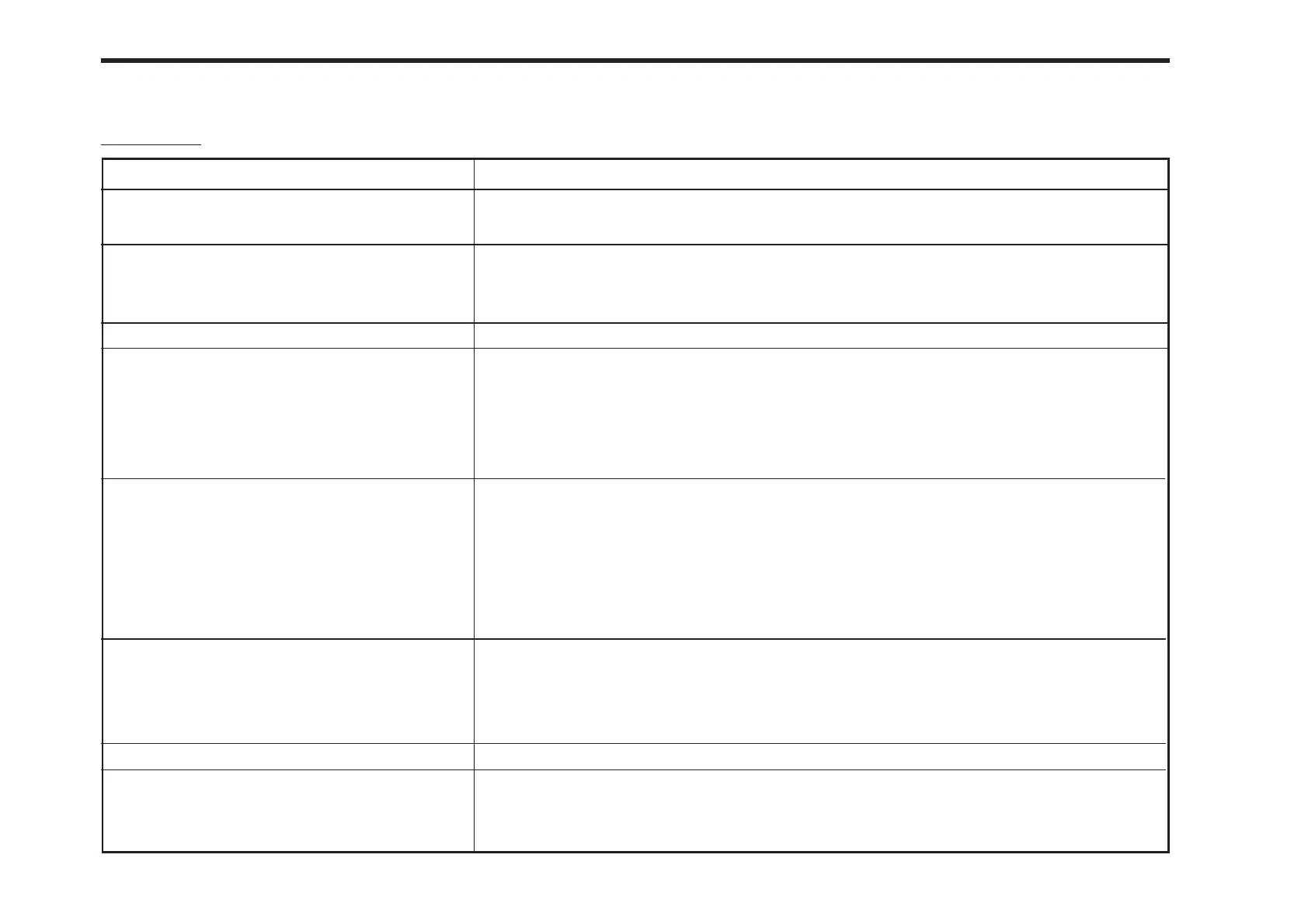

38 DIESEL ENGINE

POSSIBLE CAUSE

!!

!!

! Check and clean injection nozzles, being careful not to damage the orifice.

!!

!!

! Replace injection nozzle(s) if not working properly after cleaning.

!!

!!

! Check valves for leakage – grind valves to correct.

!!

!!

! Check for bad valves, piston wear, ring damage or wear, or liner wear.

Have parts replaced.

!!

!!

! Check and service fuel system

!!

!!

! Check for and repair leaks. Fill to correct oil level.

!!

!!

! Check for clogged oil filter and replace.

!!

!!

! Check oil pump and lubrication system.

!!

!!

! Check to see if engine bearing clearance is within specifications.

!!

!!

! Follow oil and filter service instructions to prevent future occurrences.

!!

!!

! Proper injection timing (crank angle before top dead center)

- Model 3CO93: 22

o

- Model 3CO93G: 24

o

- Models 3A139, 3A165, 4A200, 4A220: 18

o

- Models TD1300, TD1400, TD1700: 20

o

- Model 4A200T, 4A220T: 12

o

!!

!!

! Check and adjust valve clearance when the engine is cold.

-

Models 3CO93, 3CO93G, TD1300, TD1400, TD1700: intake 0.1mm, exhaust 0.1mm

- Models 3A139, 3A165, 4A200, 4A220: intake 0.25 mm, exhaust 0.30 mm

- Model 4A200T, 4A220T: intake 0.15mm, exhaust 0.15 mm

!!

!!

! Clean or replace the element every 100hours of operation.

!!

!!

! Check the injection pump and valve assembly. Replace as required.

!!

!!

! NOTE: Poor quality fuel or improper fuels will accelerate injection pump wear.

!!

!!

! Adjust to proper pressure 140~150 kgf/cm

2

(13.73~14.7Mpa, 1991~2133psi)

Clogged or faulty fuel injector

Low compression

Insufficient fuel flow

Seizure of moving parts

Incorrect fuel injection timing

Improper valve clearance

Dirty air cleaner

Fuel injection pump wear

PROBLEM: LOW ENGINE POWER OUTPUT

CORRECTIVE ACTIONS

Loading...

Loading...