(2) Reassembly

a. After removing carbon deposit,

submerge the nozzle in diesel oil

and clean it.

b. Replace all the gaskets with new

ones.

c. Assemble the parts and tighten

them to specified torque.

(3) Adjustment

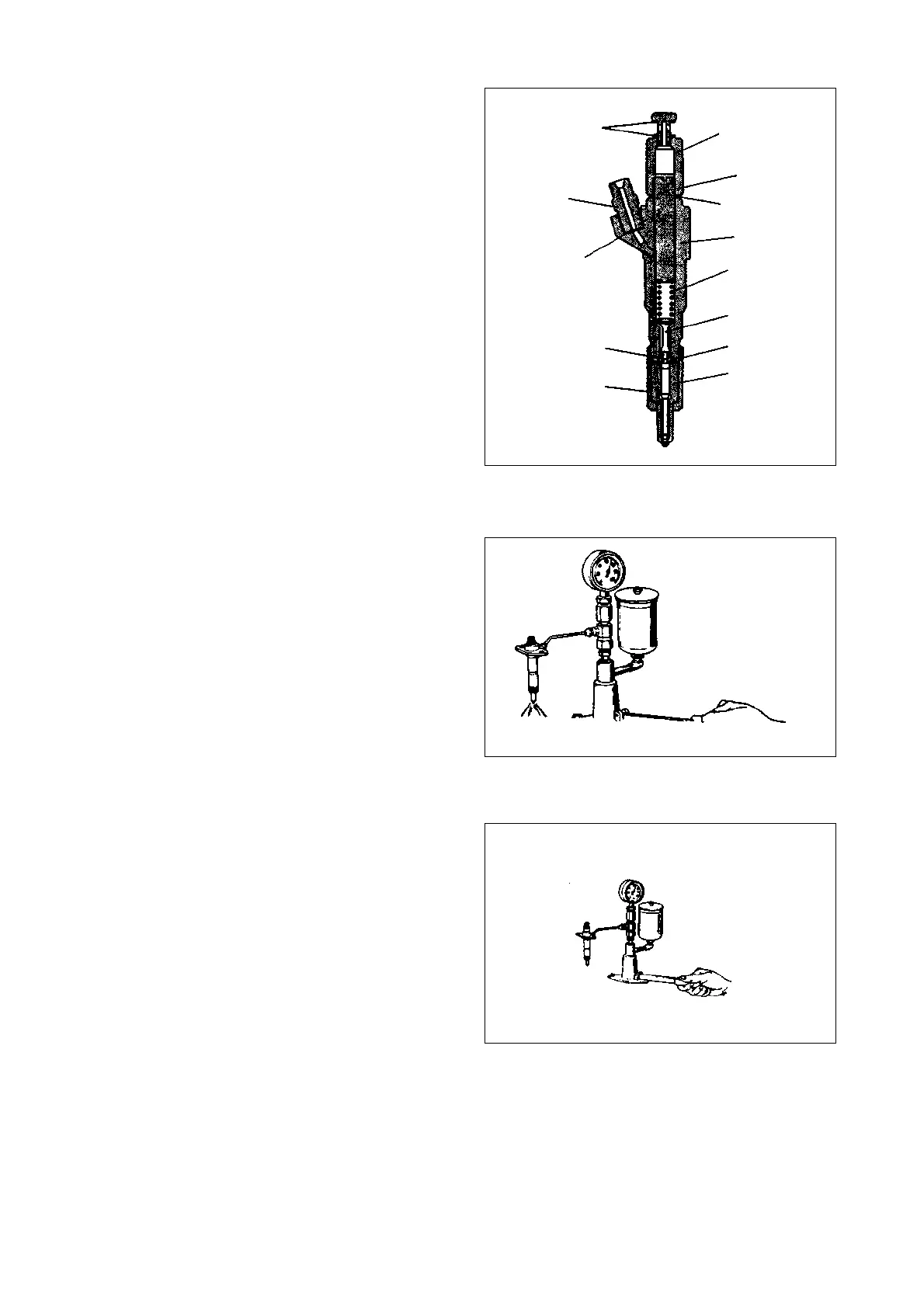

a. Remove the cap nut and assemble

a nozzle to a nozzle tester.

b. With the adjusting screw loosened,

operate the nozzle 2~3 times to

bleed it.

c. Operate the nozzle tester lever at

the specified rate.

d. Adjust the injection pressure to

the standard pressure using the

adjusting screw.

e. After adjusting the injection pressure,

tighten the cap nut to specified

torque.

f. Re-check the injection pressure and

see if the spray pattern is normal.

(4) Testing

With the nozzle assembled to a nozzle

tester and pressure of 200~210 bar

applied, check the nozzle for fuel leak-

age.

- 108 -

EQM4026S

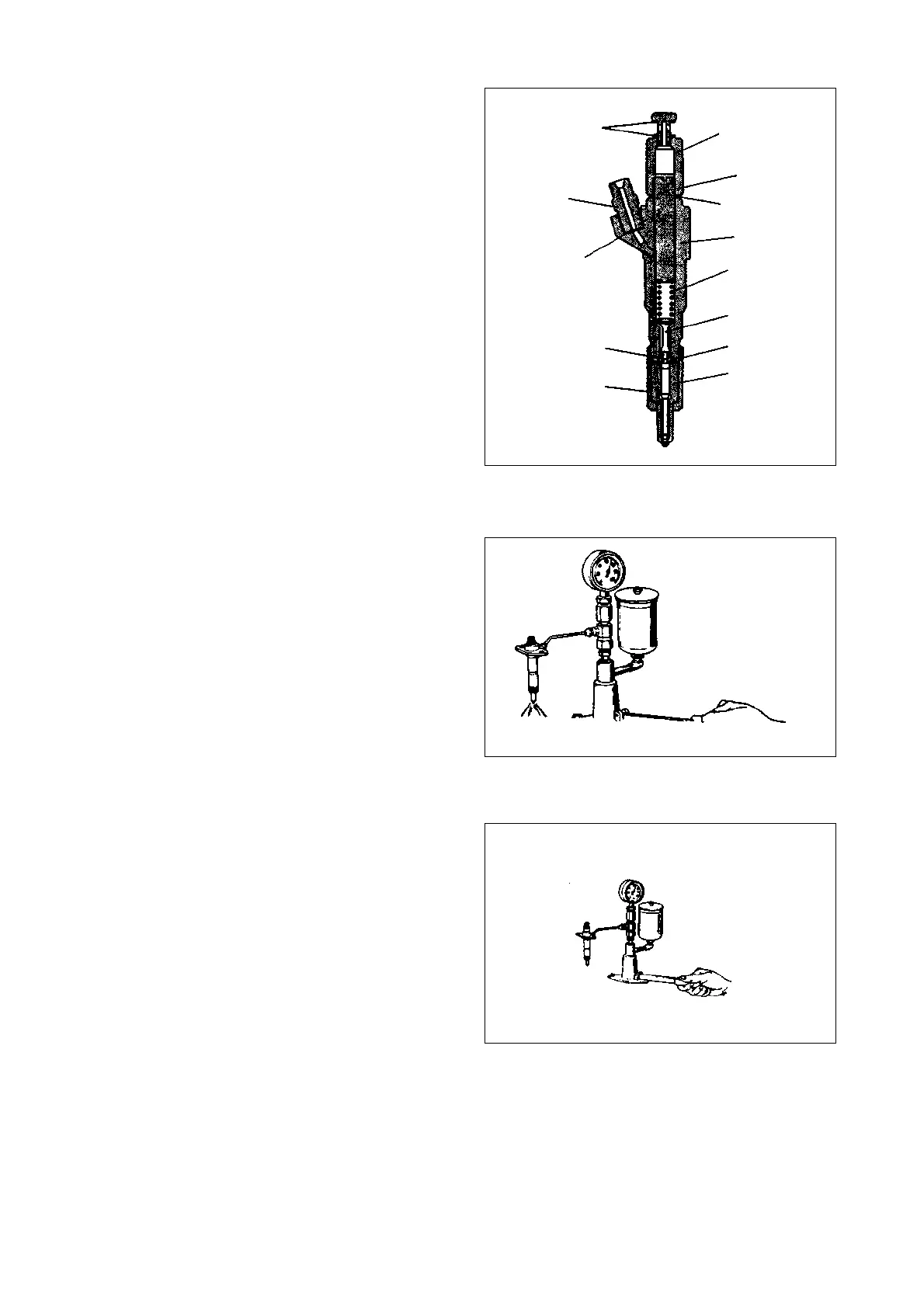

1

2

9

3

4

8

7

5

Replace

gaskets

Replace

gaskets

Replace

gaskets

Locating pin

4~5kg

•

m

<Figure 4-20>

<Figure 4-21>

<Figure 4-22>

EQM4027S

EQM4028S

Loading...

Loading...