4.4.6. Periodical checking and servicing

Make it a rule to check the turbocharger assembly for condition and contamination periodically.

1) Guide for checking the rotor for rotating condition

The inspection of the rotor assembly for rotating condition should be performed by the degree

of unusual sound. If a sound detecting bar is used, install its tip on the turbocharger housing and

increase the engine revolutions slowly. If a high-pitch sound is heard continuously, it means that

the rotor assembly is not normal. In this case, as the metal bearing and rotor are likely to be in

abnormal conditions, the turbocharger should be replaced or repaired.

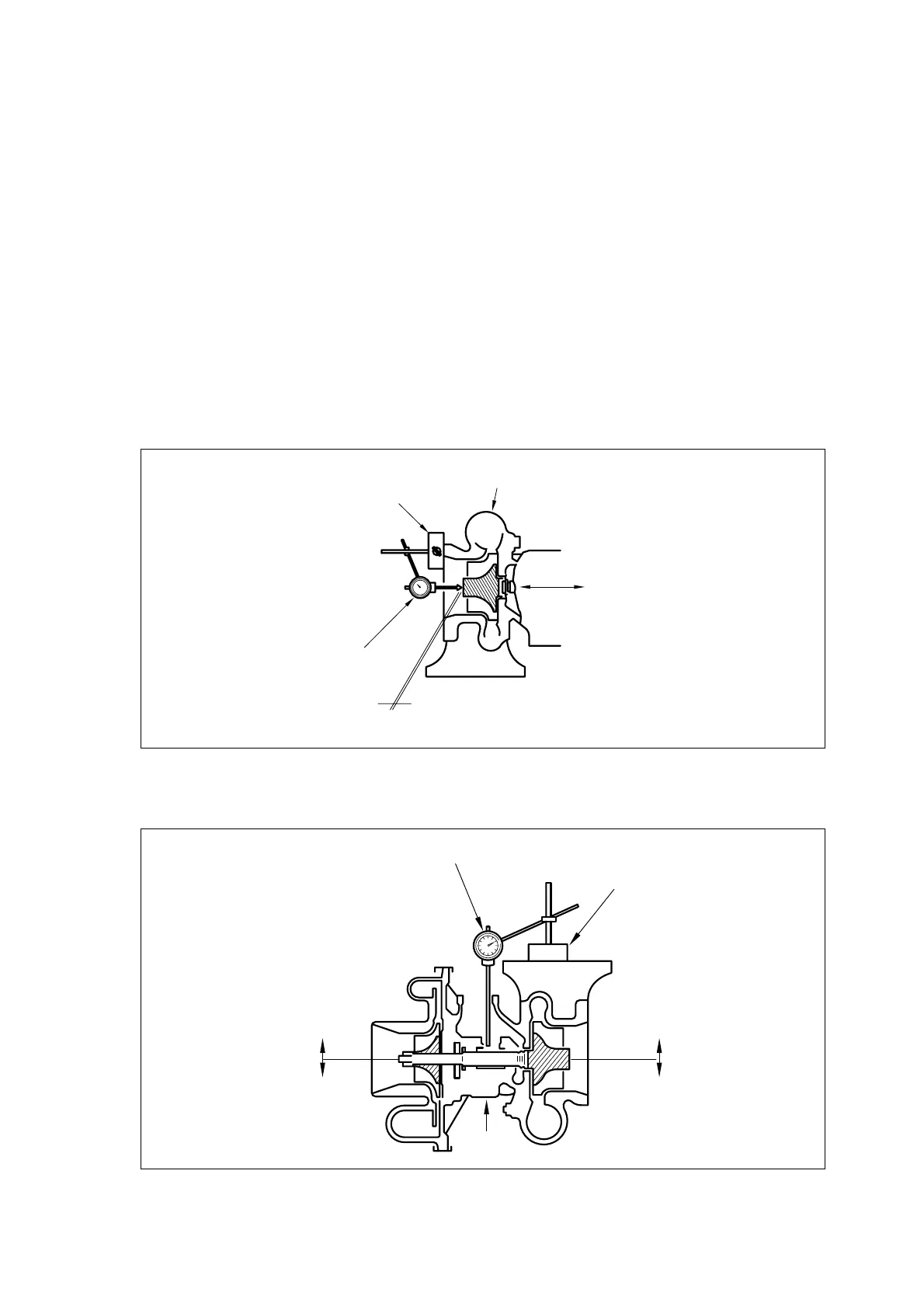

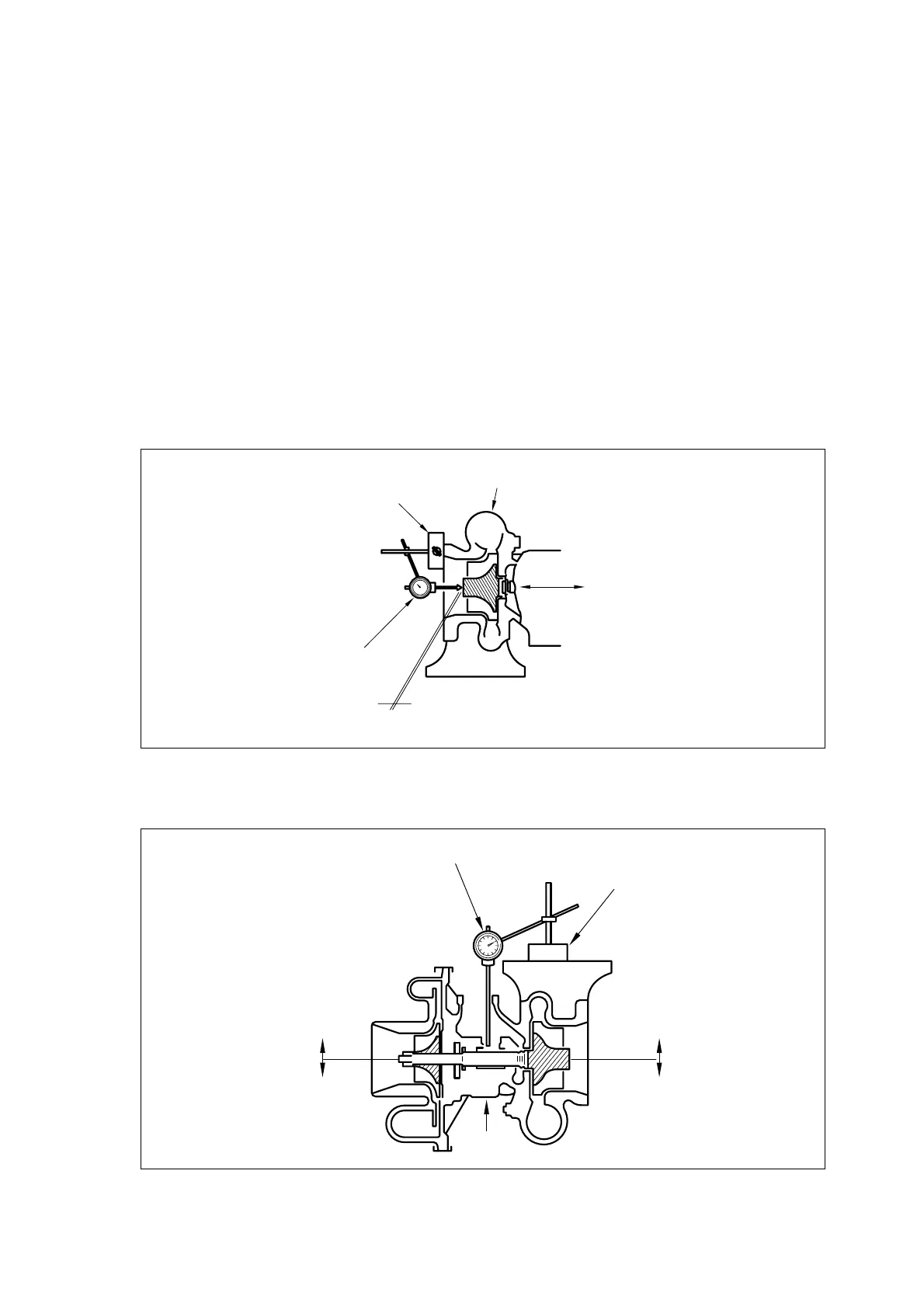

2) Guide for checking rotor end play

Disassemble the turbocharger from the engine, then check the rotor axial play and radial play.

When disassembling the turbocharger, be sure to plug the oil inlet and outlet ports with tape, etc.

(1) Rotor axial play

- 140 -

Loading...

Loading...