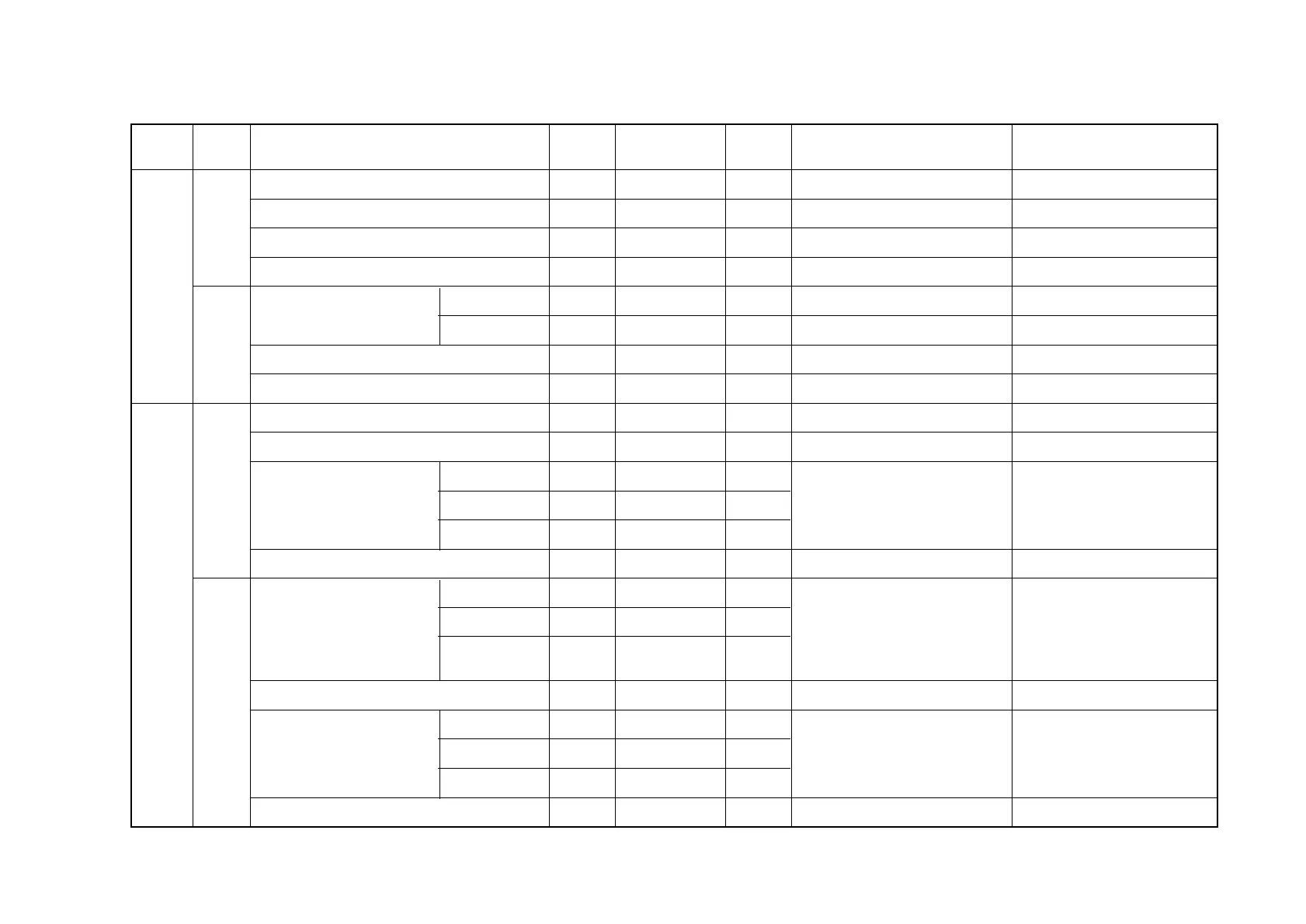

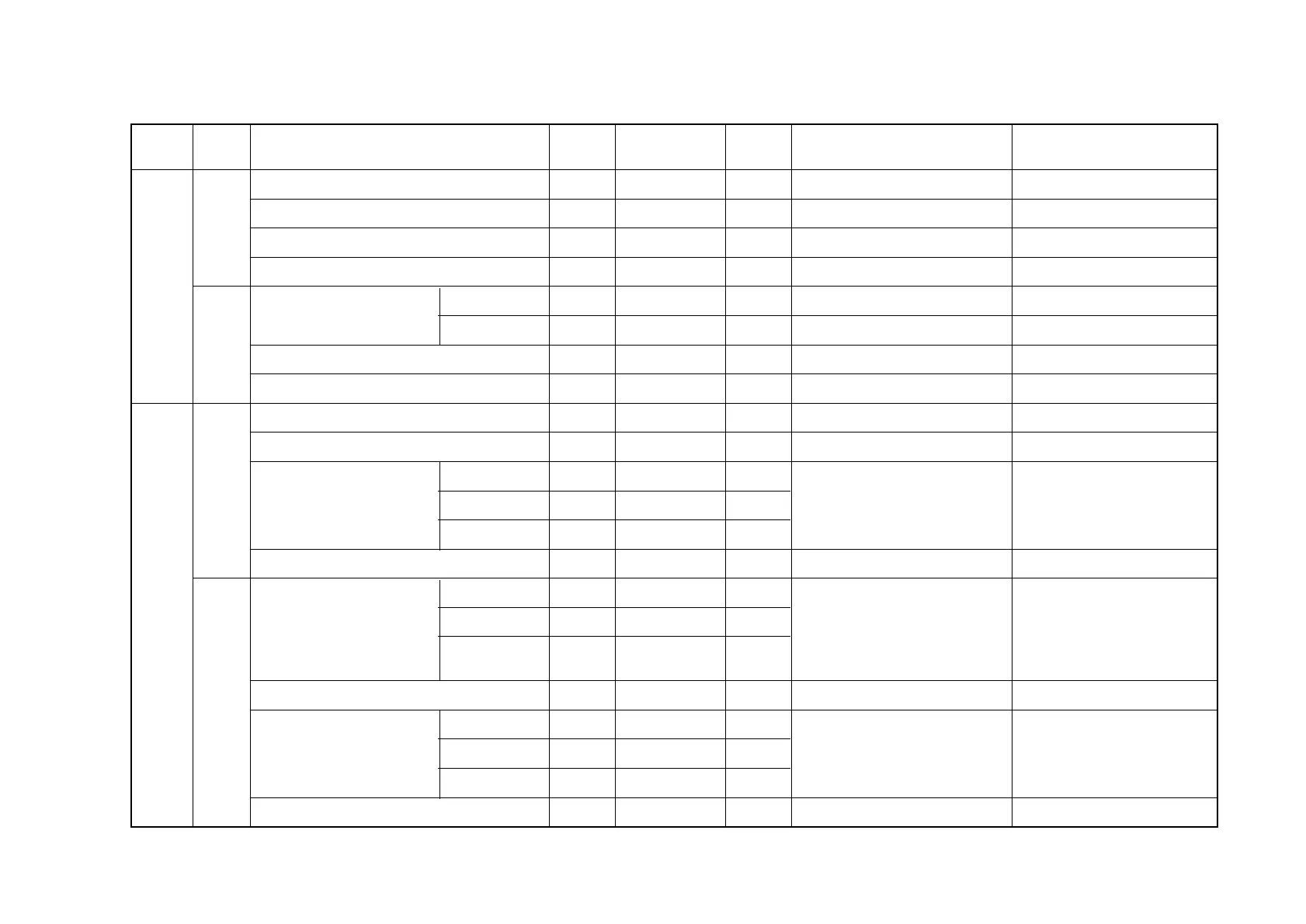

- 156 -

Assembly

Part Check items

Nominal Standard value Limit for

Correction Remarks

value for assembly use

Inside diameter of cyl. liner for wear 123 123~123.025 123.22 Replace liner

Cylinder

Projected portion of liner 0.03~0.08 5

block

The upper surface of cylinder block for distortion

0.05

Correct with a surface grinder

Per distortion length for 200mm

Engine

Hydraulic test for 1 minute (kg/cm

2

) 4 Replace if leaky

body

Valve seat depression

Intake -0.3~0

In case of new valve and valve seat

Cylinder

Cylinder head

Exhaust -0.3~0 -0.55

head

Height 114.9~115 -0.55 Replace cyl. head

Hydraulic test for 1 minute (kg/cm

2

) 4 113.9 Replace if leaky Water temp : 70C

Piston diameter(18mm from the lower side)

122.433~122.863

Clearance between piston and liner 0.123~0.162

Piston Tor ring 3.5

Width of piston ring

2nd ring 3.060~3.080

Replace piston if groove width

grooves

Oil ring 4.040~4.060

is beyond specified value

Major

Piston projection from cylinder block upper surface

0~0.12

moving Top ring 0.30~0.45 1.5

parts Piston ring gap 2nd ring 0.35~0.50 1.5 Standard gauge inside

Oil ring

0.30~0.50 1.5 diameter : N123

*0.4~0.7

Piston

Permissible weight difference of each piston

96g

ring Top ring

2nd ring 0.07~0.102 0.15 Replace ring or piston

Limit for use if for

Oil ring 0.05~0.085 0.15

standard clearance

Direction of ring gap Install ring by 120°

6.2. Maintenance specification table

Measure unworn portion beneath

the rim of the upper side

Measure unworn portion beneath

the rim of the upper side

*Adapted only in DE12TIS

Loading...

Loading...