6) Coat the push rod with engine oil and

insert it into the push rod hole.

7) Mount the rocker arm assembly on the

cylinder head and tighten the rocker

arm bracket fixing bolts to specified

torque(4.4kg

•

m).

8) Adjust the valve clearance.

•

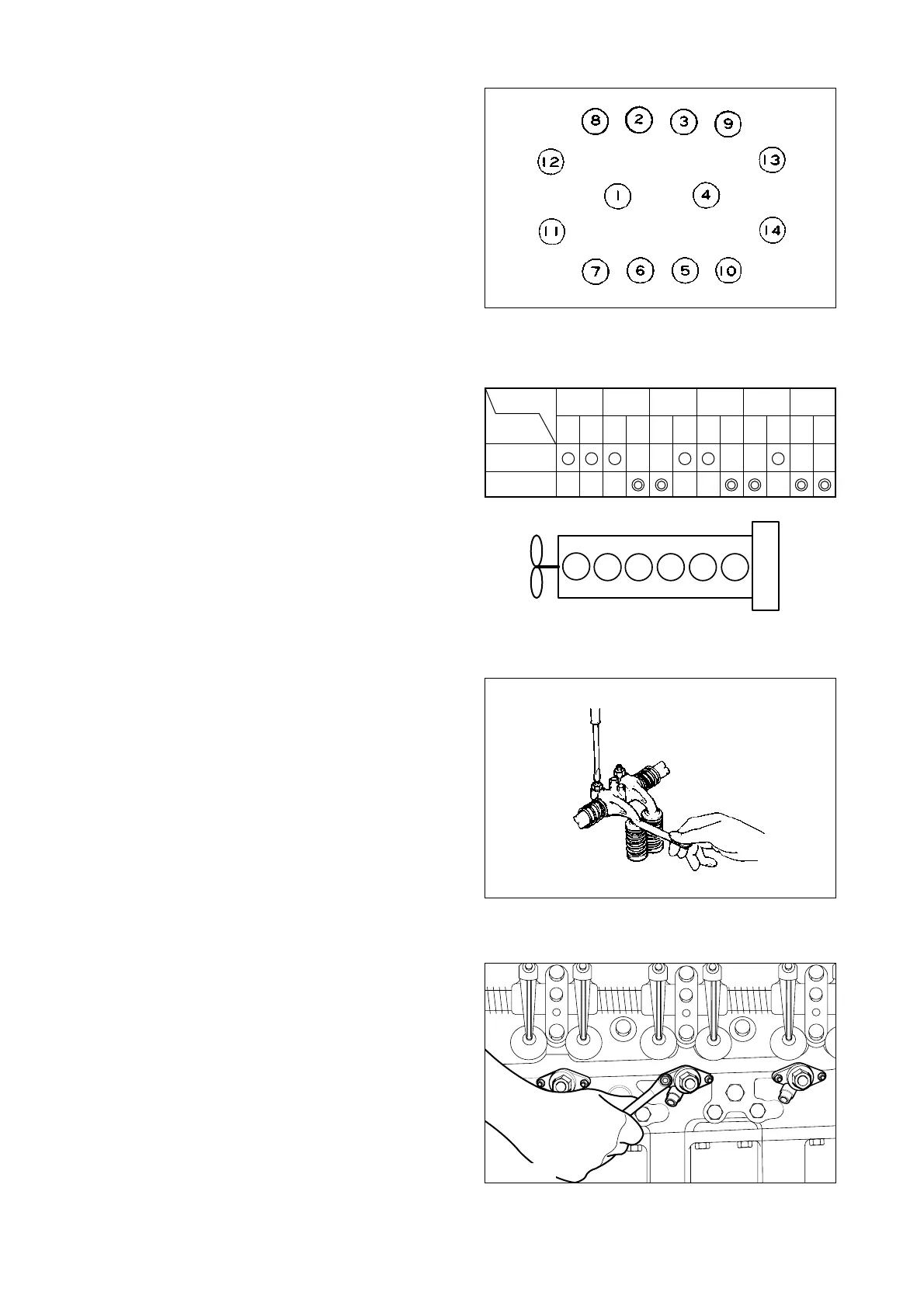

Guide for valve clearance adjustment

- Place No. 1 piston in the "OT" position

and adjust valve clearance at six posi-

tions as shown in th right-hand figure.

At this time, the intake and exhaust

valves of No. 6 cylinder are in an over-

lapped state.

- Turn the crank 360 degrees to bring the

No. 6 piston in the "OT" position, then

adjust the remaining valve clearance.

- Determine the sequence of the cylinders

and intake/exhaust valves beginning

with the flywheel housing size.

- Intake valve clearance : 0.3mm

- Exhaust valve clearance : 0.3mm

9) Adjust valve clearance with a feeler

gauge and tighten the fixing nuts to

specified torque(4.4kg

•

m).

- 71 -

EQM3082I

EDM1003S

EQM3083I

<Tightening sequence of cylinder head fixing

bolts>

ENGINE TOP VIEW

•

Cylinder No.

Cylinder No.

123456

IN EX IN EX IN EX IN EX IN EX IN EX

No. 1 TDC

No. 6 TDC

Adjusting

valve

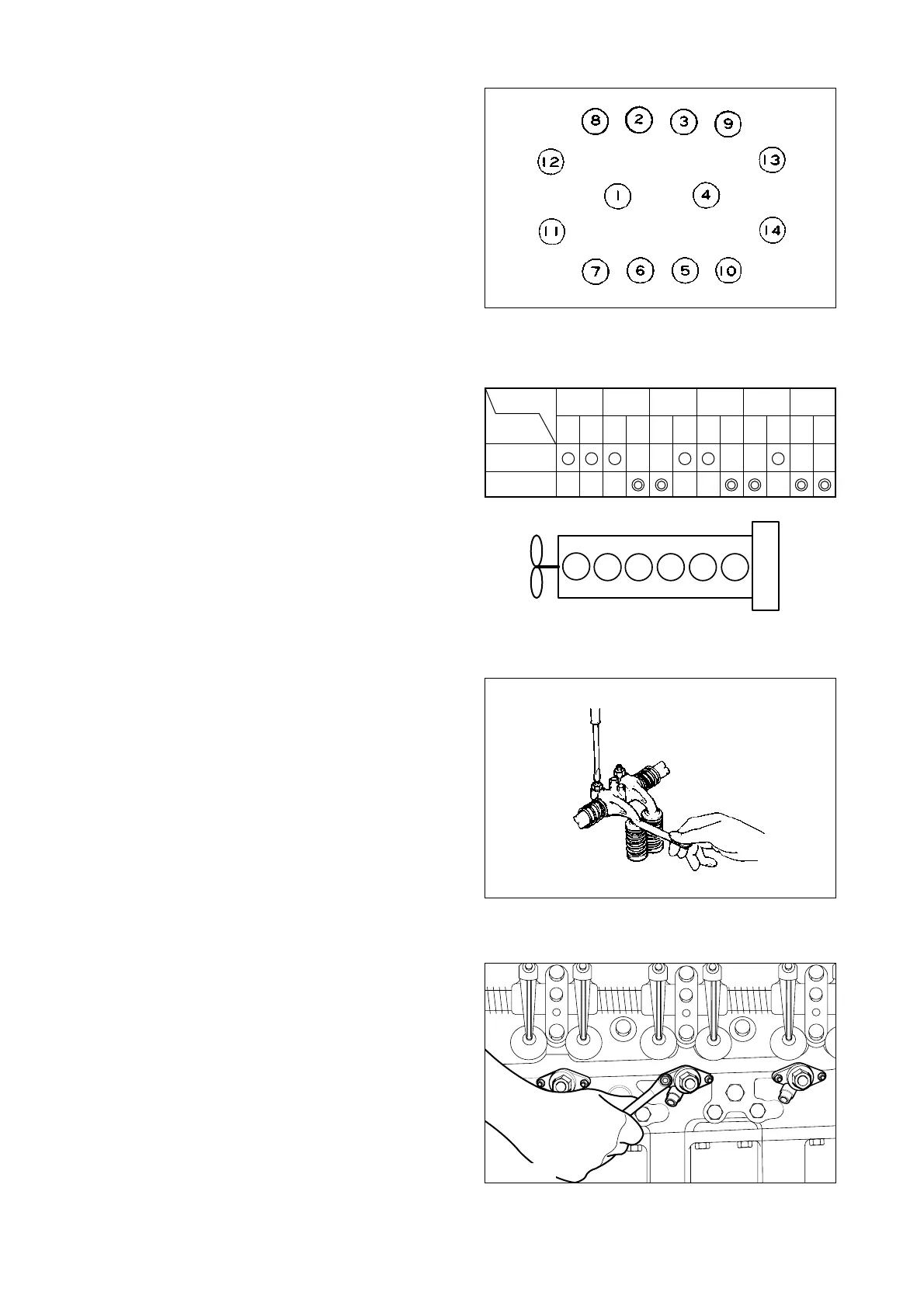

3.3.23. Injection nozzle

1) Install the dust seal with its round portion

facing downward.

2) Mount a seal ring(0.5mm) on the seal

ring seating surface of the nozzle tube

and assemble it with the stud bolt with

the nozzle pipe installing direction facing

outward.

3) Be sure to follow the specified torque

(1.0kg

•

m).

Flywheel housing side

Cooling fan side

Loading...

Loading...