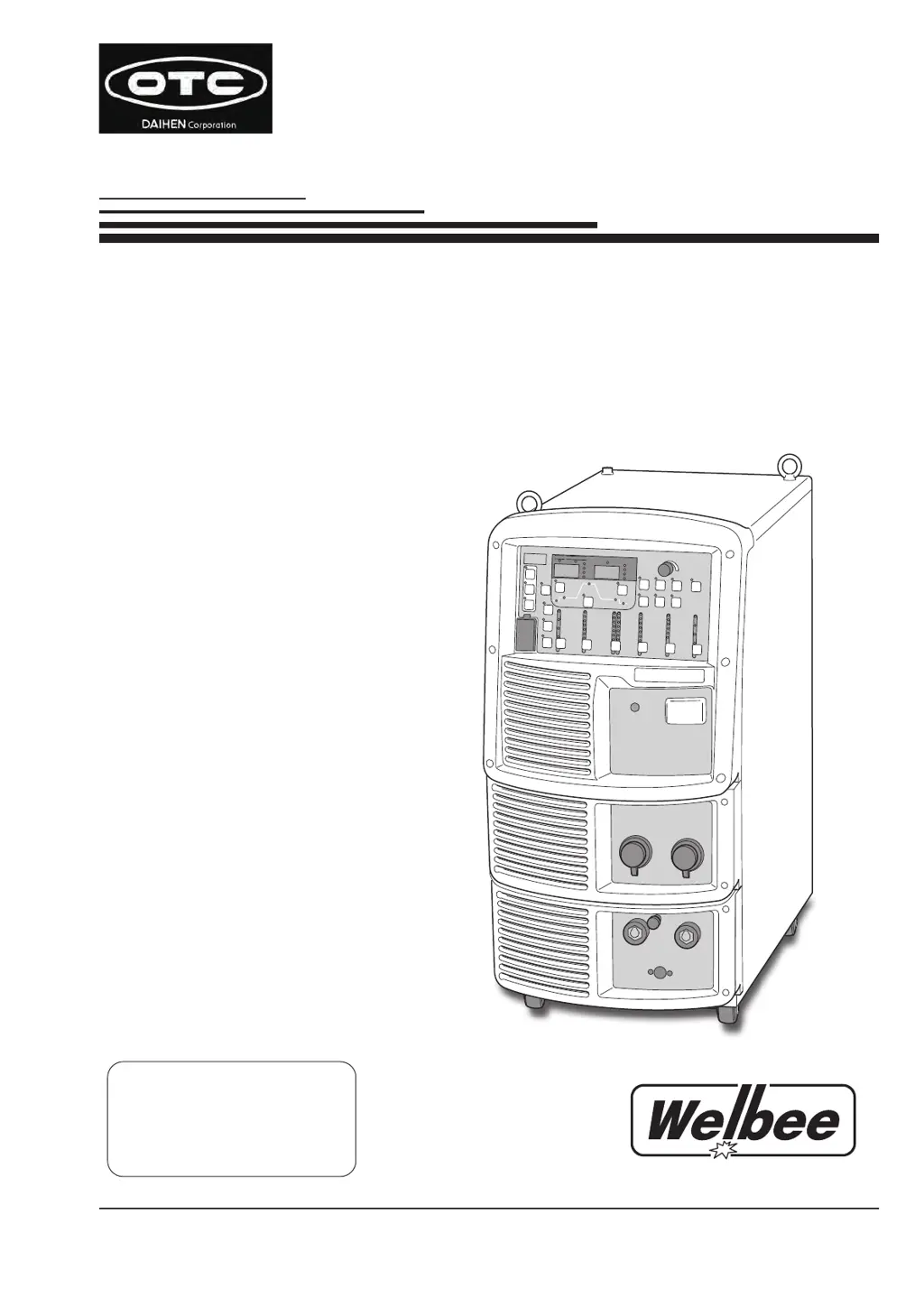

What to do if shielding gas is not flowing in my Daihen Welding System?

- GGabriel CardenasAug 6, 2025

If the shielding gas isn't flowing in your Daihen Welding System, first, make sure the gas cylinder valve is open. If it is open, the gas cylinder pressure may be too low; in that case, replace the gas cylinder. Also, verify that the external input settings (internal functions F29 to F32) are correct.