9 nEnglish

Refrigerant Piping Work

Precautions for Laying Refrigerant Piping

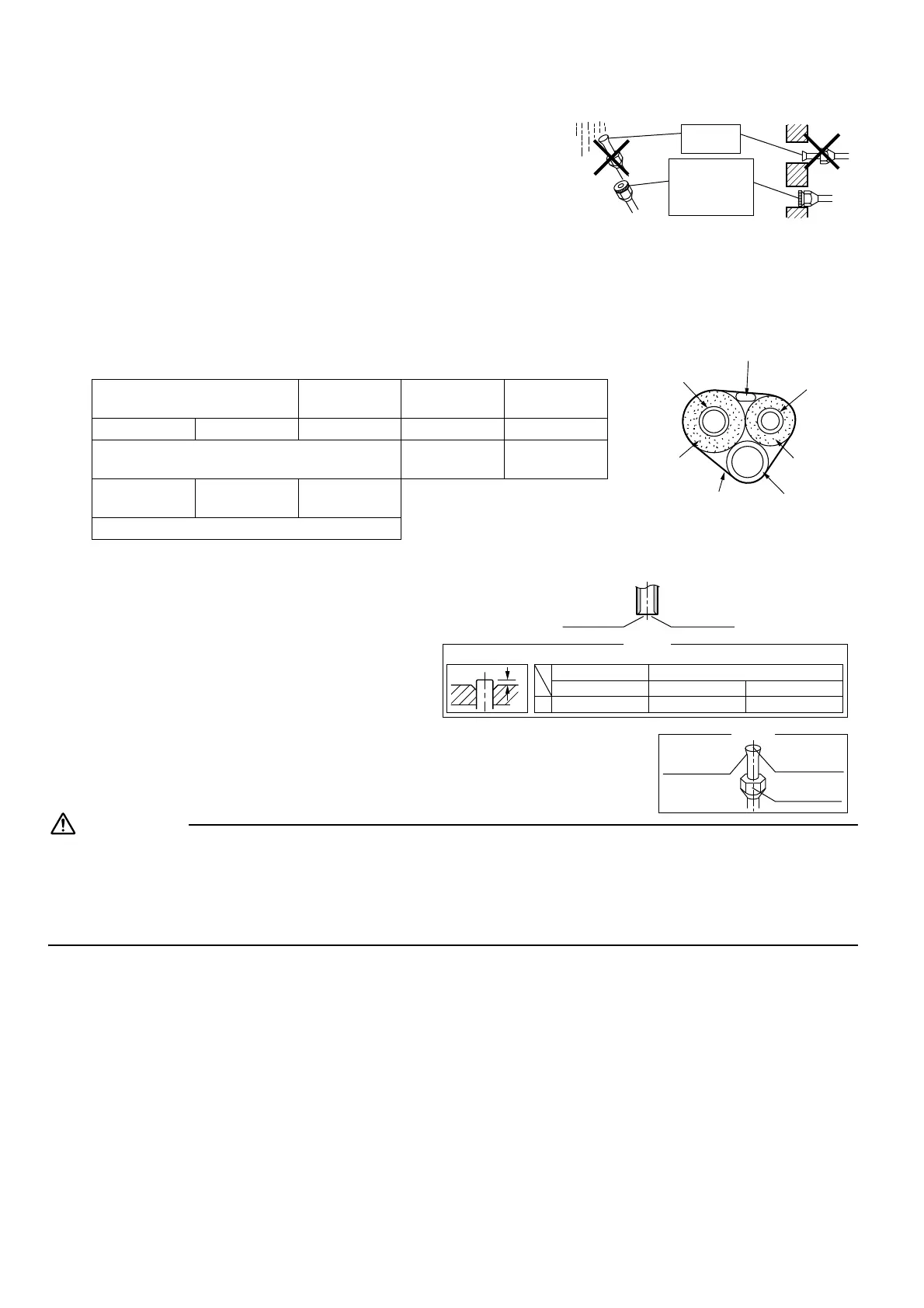

• Cautions on pipe handling

1) Protect the open end of the pipe against dust and moisture.

2) All pipe bends should be as gentle as possible. Use a pipe bender for

bending.

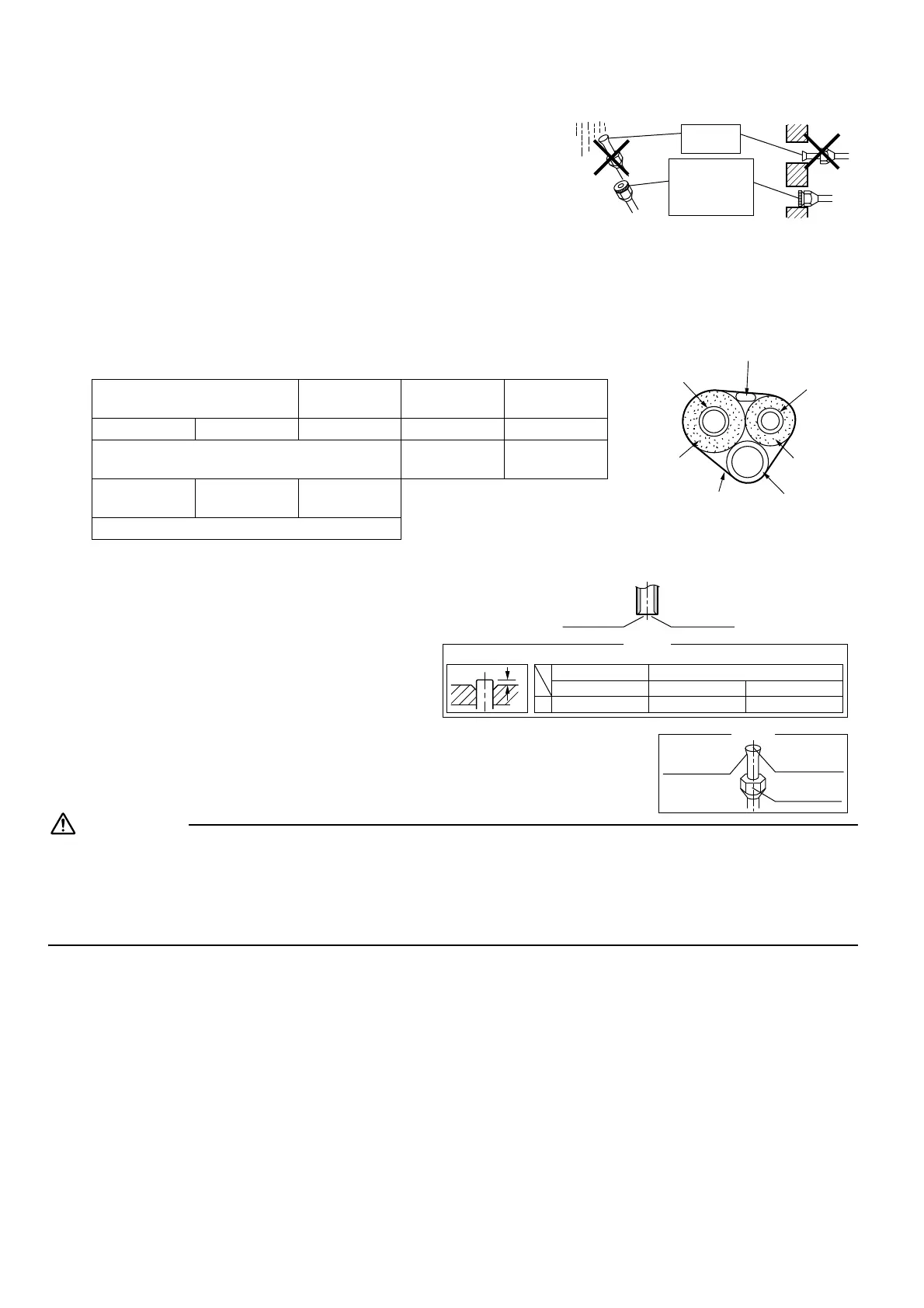

• Selection of copper and heat insulation materials

When using commercial copper pipes and fittings, observe the following:

1) Insulation material: Polyethylene foam

Heat transfer rate: 0.041 to 0.052W/mK (0.035 to 0.045kcal/mh°C)

Refrigerant gas pipe’s surface temperature reaches 110°C max.

Choose heat insulation materials that will withstand this temperature.

2) Be sure to insulate both the gas and liquid piping and to provide insulation dimen-

sions as below.

3) Use separate thermal insulation pipes for gas and liquid refrigerant pipes.

• Flaring the pipe end

1) Cut the pipe end with a pipe cutter.

2) Remove burrs with the cut surface facing down-

ward so that the chips do not enter the pipe.

3) Put the flare nut on the pipe.

4) Flare the pipe.

5) Check that the flaring is properly made.

• Do not use mineral oil on flared part.

• Prevent mineral oil from getting into the system as this would reduce the lifetime of the units.

• Never use piping which has been used for previous installations. Only use parts which are delivered with the unit.

• Never install a dryer to this R410A unit in order to guarantee its lifetime.

• The drying material may dissolve and damage the system.

• Incomplete flaring may cause refrigerant gas leakage.

Gas pipe Liquid pipe

Gas pipe

insulation

Liquid pipe

insulation

O.D.9.5mm O.D.12.7mm O.D.6.4mm I.D.12-15mm I.D.8-10mm

Minimum bend radius

Thickness

13mm min.

Thickness

10mm min.

30mm or

more

40mm or

more

30mm or

more

Thickness 0.8mm (C1220T-O)

Wall

If no flare cap is

available, cover

the flare mouth

with tape to keep

dirt or water out.

Be sure to

place a cap.

Rain

Gas pipe

Liquid pipe

Gas pipe

insulation

Liquid pipe

insulation

Finishing tape

Drain hose

Inter-unit wires

(Cut exactly at

right angles.) Remove burrs

Set exactly at the position shown below.

A

Flaring

Die

Check

Flare’s inner

surface must

be flaw-free.

The pipe end must

be evenly flared in

a perfect circle.

Make sure that the

flare nut is fitted.

A 0-0.5mm

Clutch-type

Flare tool for R410A

1.0-1.5mm

Clutch-type (Rigid-type)

1.5-2.0mm

Wing-nut type (Imperial-type)

Conventional flare tool

Loading...

Loading...