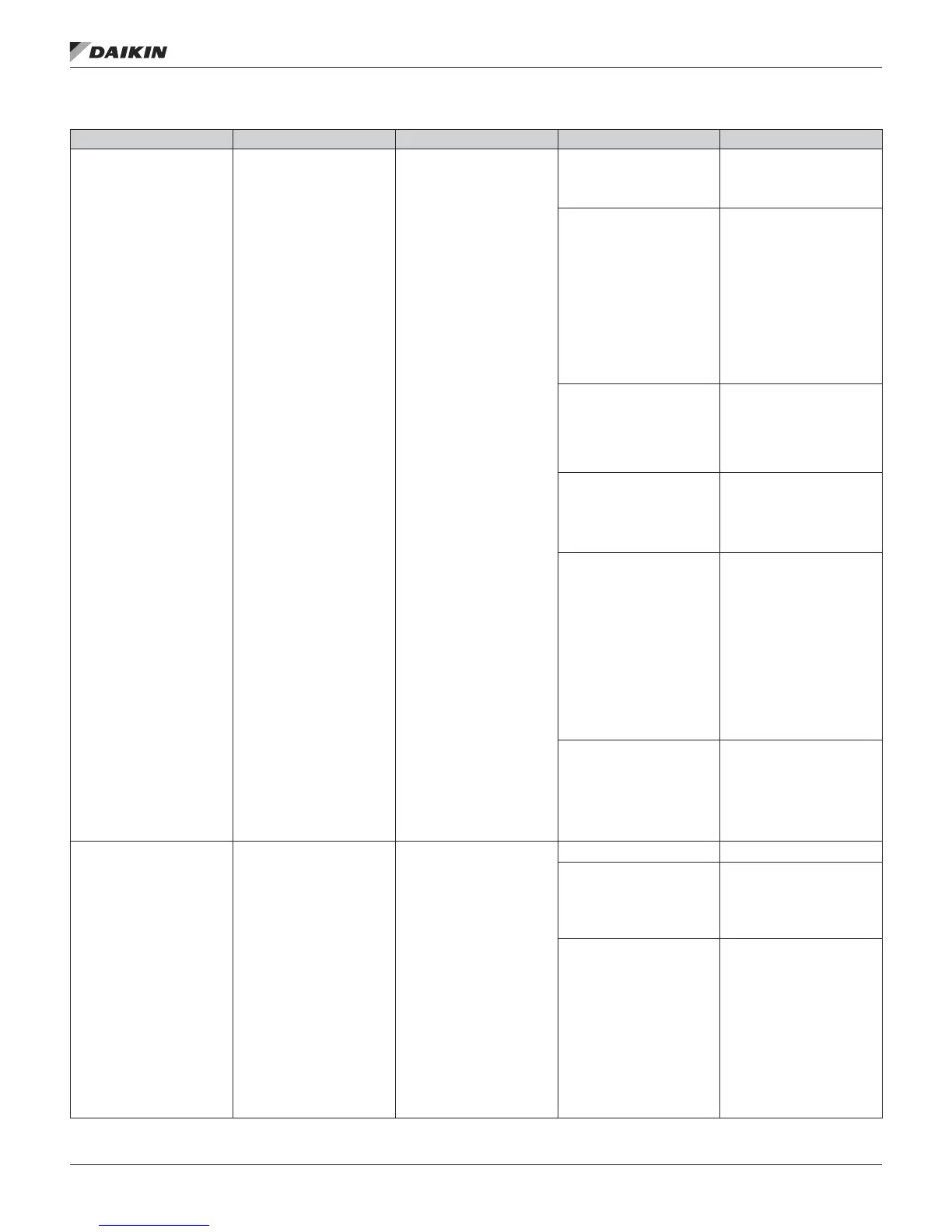

Table 24 continued: Functional Alerts

Display Information Alert Description Possible Cause Solution

AO4

Limited Low Fire

Automatic adaptive

program is currently

limiting the lower range

of modulation at avoid

ame loss at minimum re

conditions. The alert is

displayed during the run

cycle once a ame-out

condition has triggered the

Limited Low Fire function.

This function is reset by

cycling power to the board.

A. Low gas line pressure

1. Insure gas supply is

connected to furnace

and check for proper

line pressure.

B. Insufcient intermediate

gas manifold pressure

through gas safety

valve

1. Check for faulty gas

valve wiring.

2. Check 24 VAC to gas

valve assembly.

3. Check inlet pressure to

safety gas valve.

4. Check outlet pressure

from the safety gas

valve – adjust as

needed.

5. Replace safety gas

valve if faulty.

C. Faulty burner operation

1. Check for proper

mounting of the burner

assembly.

2. Check burner orice

for proper size and

blockage.

D. Faulty ame sensor

1. Check ame rod wiring

and connections.

2. Check for proper

alignment of ame rod.

3. Clean ame rod sensor.

E. Improper alignment of

the modulating actuator

and the gas ball valve

1. Check that the

alignment of the

actuator to the ball

valve is correct. The

ball valve must be in

the fully open position

when the actuator

is fully energized

(“ACTUATOR DRIVE”

= 9.6 VDC or greater).

2. Insure that the set

screw on the actuator

is tightened to the ball

valve stem.

F. Blocked or improper

venting

1. Check air inlet and

outlet for blockage.

2. Check venting

conguration for

excessive venting

length, improper sizing,

etc.

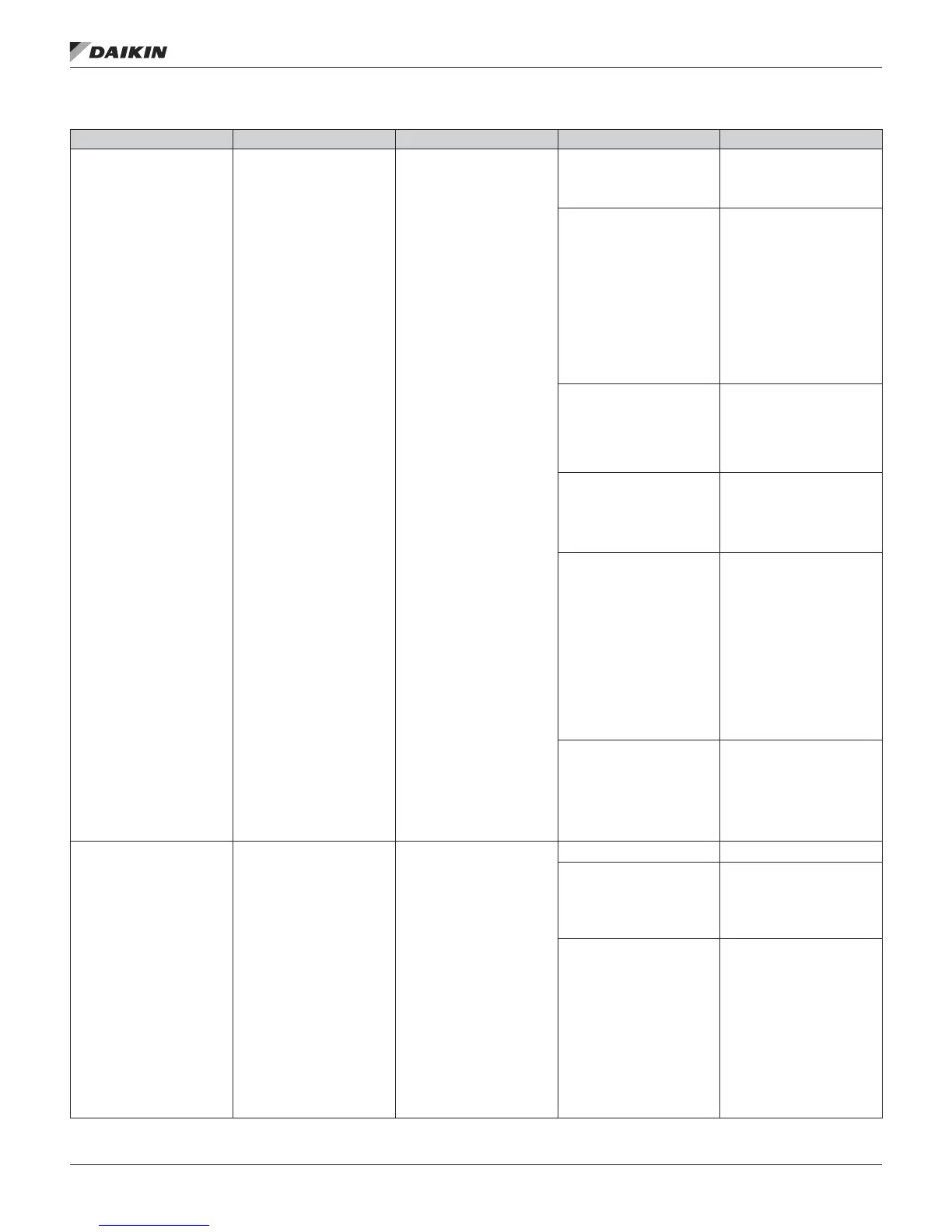

AO5

Weak Flame Signal

The ame signal level is

less than optimal for this

furnace. Maintenance

of the ame sensing

components is advised.

A. Flame sensor coated 1. Clean ame rod sensor.

B. Flame sensor

improperly mounted or

grounded

1. Check ame sensor

wiring integrity and

ceramic for cracks.

2. Re-install / replace

ame sensor.

C. Unstable ame pattern

1. Check that all burner

assembly components

are properly installed.

2. Check that all seals

between the vestibule

area and the heat

exchanger area are

tight.

3. Insure that the

combustion door

gasket is in place and

the door is properly

installed.

IM 1125-7 • REBEL ROOFTOPS 56 www.DaikinApplied.com

opTIonal gas heaT

Loading...

Loading...