Procedure to Protect Compressor in Case of Frozen Evaporator ESIE10-01

3–72 Part 3 – Troubleshooting

3

1

3

4

5

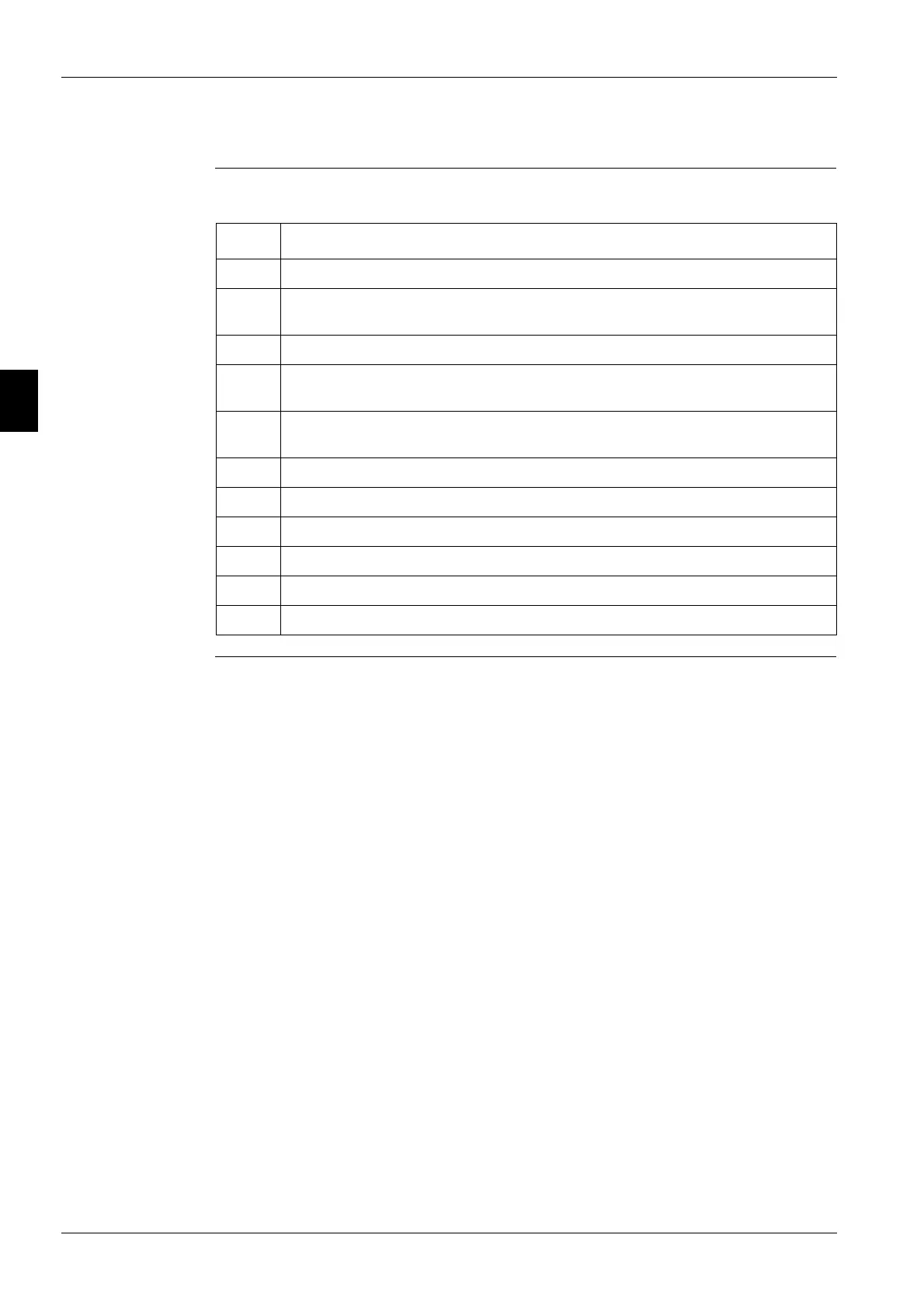

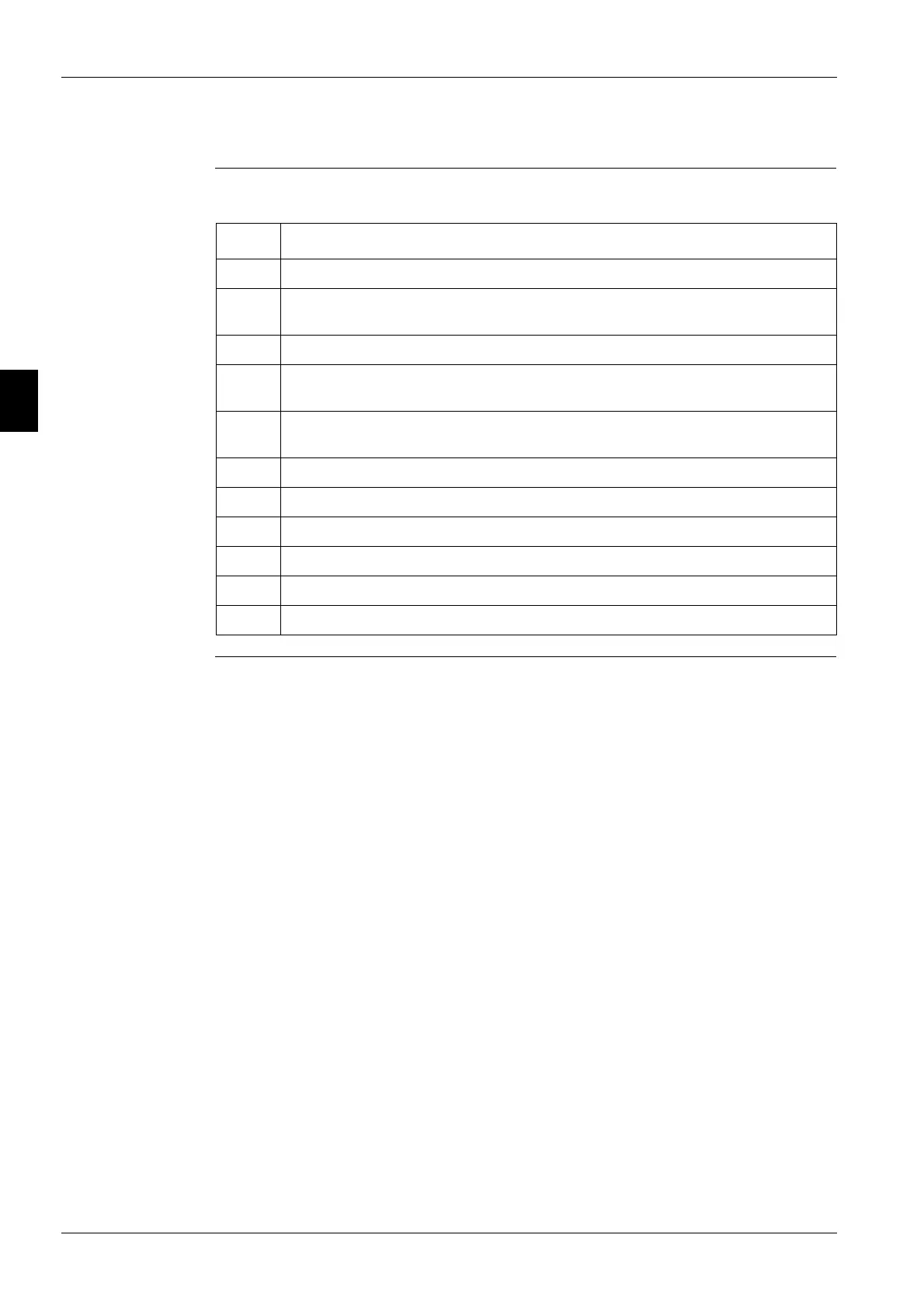

4.2 Procedure to Protect Compressor in Case of Frozen Evaporator

If water is detected in the compressor after an evaporator damage, the following procedure should be

executed within the first day.

Step Action

1 Supply the compressor crank case heater.

2 Insulate the compressor from the rest of the refrigerant circuit. If there is no suction

valve available on the compressor, use a plate to close the suction of the compressor.

3 Open the oilplugs to drain the oil and the water out of the compressor.

4 Blow-dry nitrogen through the compressor using the service ports on the HP and LP

side of the compressor.

5 Close the drain plugs and vacuum the compressor for a few hours while the crank case

heater is on.

6 If the vacuum oil becomes coloured (milky colour) replace the vacuum oil.

7 Repeat step 6 each time the vacuum oil becomes milky.

8 After 4 hours break the vacuum using step 3.

9 Repeat step 5 till step 7 until the oil of the vacuum pump becomes clear.

10 If the vacuum oil remains clear fill the compressor with the necessary compressor oil.

11 Charge the compressor with nitrogen.

Loading...

Loading...