5 Installation

Installation and operation manual

8

FFA25~60A2VEB

Split system air conditioners

4P456960-1 – 2017.03

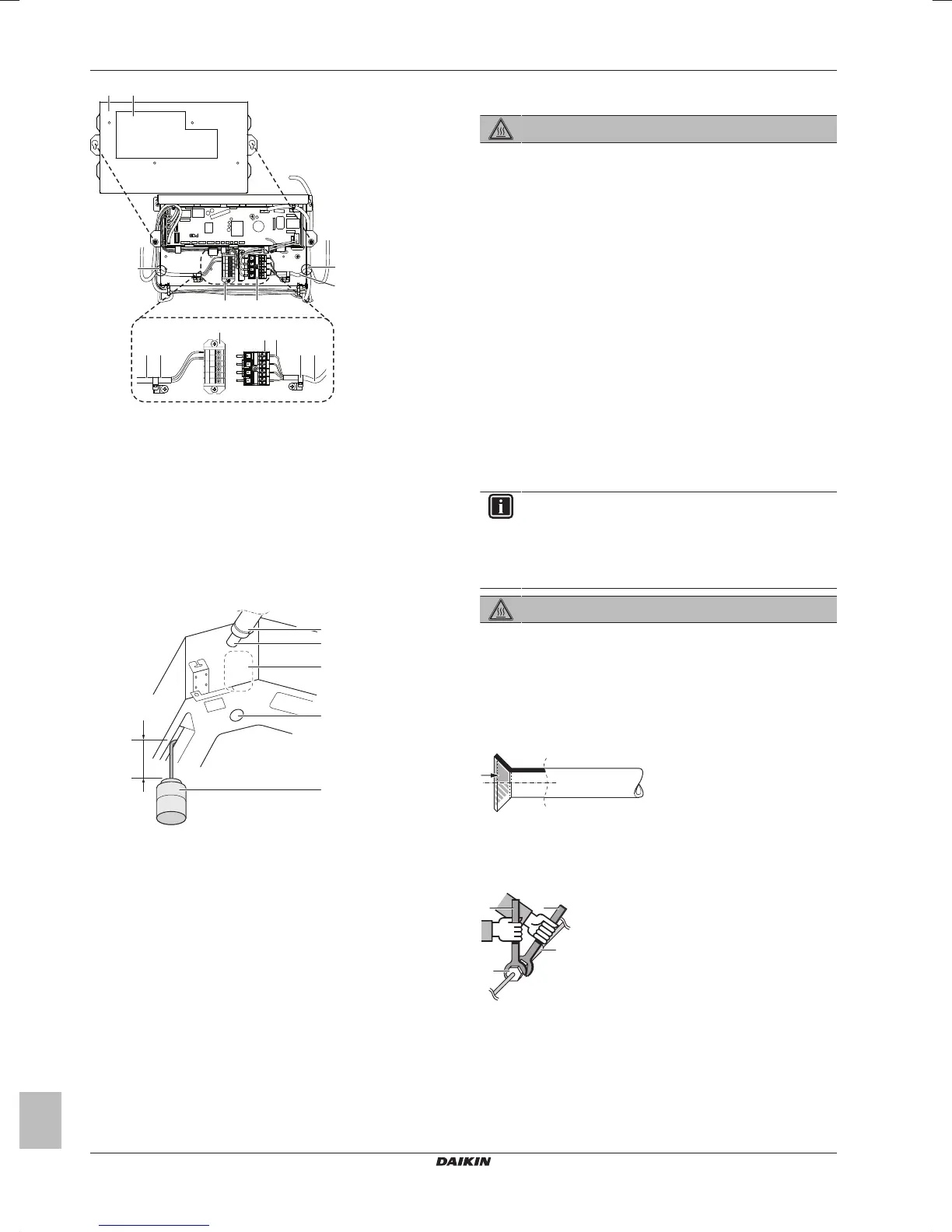

g

g

b

d

f

a h

i e

e

b

f

d

c

P1 P2

TRANSM.

WIRING

F1 F2

OFF

FORCED

T1 T2

RC

a Control box cover

b Inter-unit wiring

c Earth cable

d Terminal block for power supply

e Clamp

f Terminal board for transmission wiring

g Opening for cables

h Wiring diagram label (on the back of the control box lid)

i Remote controller wiring

2 Turn ON the power.

3 Start cooling operation (see "7.4 To perform a test run" on

page12).

4 Gradually pour approximately 1 l of water through the air

discharge outlet, and check for leaks.

a Plastic watering can

b Service drain outlet (with rubber plug). Use this outlet to

drain water from the drain pan.

c Drain pump location

d Drain pipe connection

e Drain pipe

5 Turn OFF the power.

6 Disconnect the electrical wiring.

▪ Remove the control box cover.

▪ Disconnect the power supply and earth.

▪ Reattach the control box cover.

When electrical wiring is finished already

1 Start cooling operation (see "7.4 To perform a test run" on

page12).

2 Gradually pour approximately 1 l of water through the air

discharge outlet, and check for leaks (see When electrical

wiring is not finished yet).

5.2 Connecting the refrigerant piping

DANGER: RISK OF BURNING

5.2.1 About connecting the refrigerant piping

Before connecting the refrigerant piping

Make sure the outdoor and indoor unit are mounted.

Typical workflow

Connecting the refrigerant piping involves:

▪ Connecting the refrigerant piping to the outdoor unit

▪ Connecting the refrigerant piping to the indoor unit

▪ Insulating the refrigerant piping

▪ Keeping in mind the guidelines for:

▪ Pipe bending

▪ Flaring pipe ends

▪ Brazing

▪ Using the stop valves

5.2.2 Precautions when connecting the

refrigerant piping

INFORMATION

Also read the precautions and requirements in the

following chapters:

▪ General safety precautions

▪ Preparation

DANGER: RISK OF BURNING

5.2.3 Guidelines when connecting the

refrigerant piping

Take the following guidelines into account when connecting pipes:

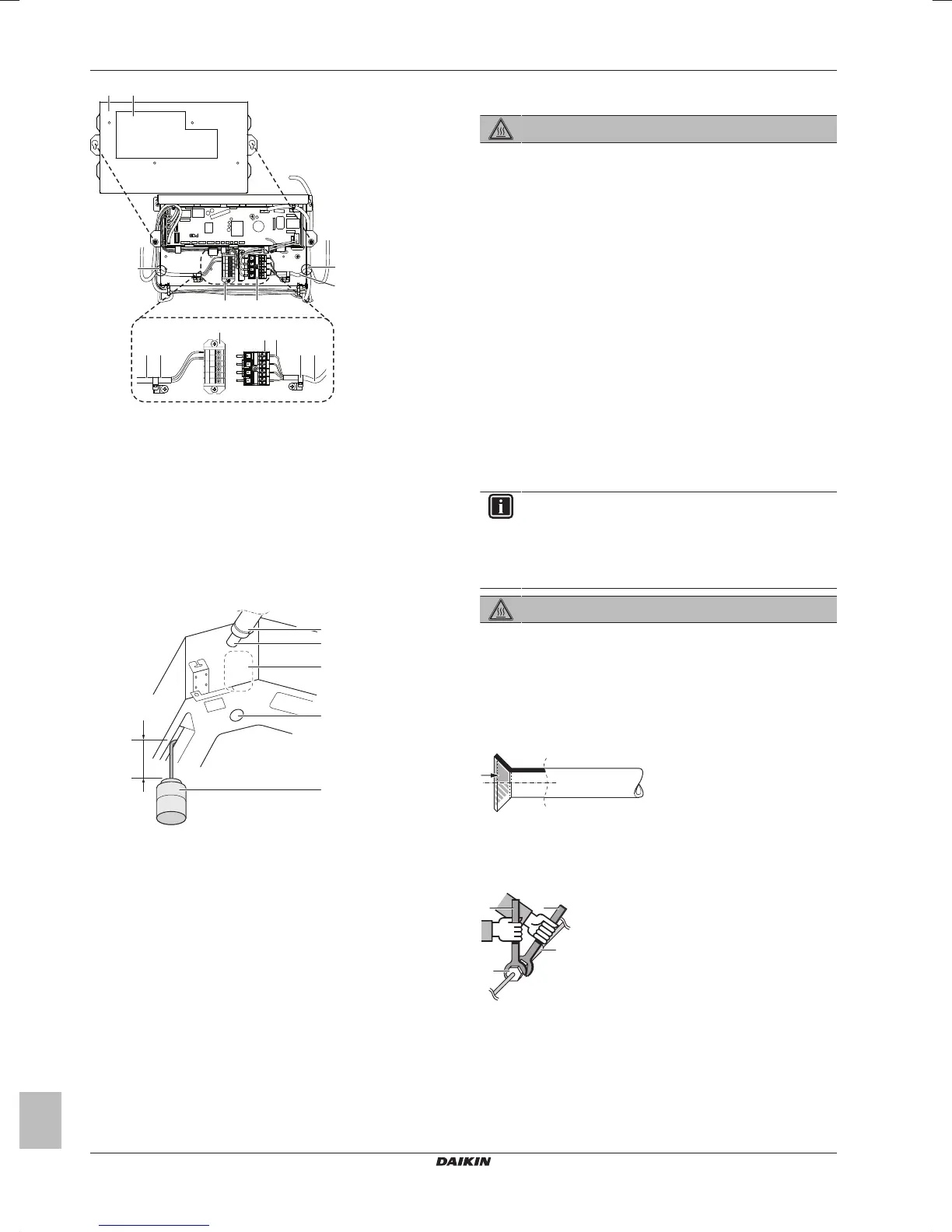

▪ Coat the flare inner surface with ether oil or ester oil when

connecting a flare nut. Tighten 3 or 4 turns by hand, before

tightening firmly.

▪ Always use 2 wrenches together when loosening a flare nut.

▪ Always use a spanner and torque wrench together to tighten the

flare nut when connecting the piping. This to prevent nut cracking

and leaks.

a Torque wrench

b Spanner

c Piping union

d Flare nut

Loading...

Loading...