17 | Piping installation

Installer and user reference guide

61

FXFA20~125A2VEB

VRV system air conditioner

4P599624-1A – 2020.06

17 Piping installation

In this chapter

17.1 Preparing refrigerant piping ................................................................................................................................................... 61

17.1.1 Refrigerant piping requirements ........................................................................................................................... 61

17.1.2 Refrigerant piping insulation.................................................................................................................................. 62

17.2 Connecting the refrigerant piping.......................................................................................................................................... 62

17.2.1 About connecting the refrigerant piping............................................................................................................... 62

17.2.2 Precautions when connecting the refrigerant piping............................................................................................ 63

17.2.3 Guidelines when connecting the refrigerant piping.............................................................................................. 63

17.2.4 Pipe bending guidelines ......................................................................................................................................... 64

17.2.5 To flare the pipe end.............................................................................................................................................. 64

17.2.6 To connect the refrigerant piping to the indoor unit............................................................................................ 65

17.1 Preparing refrigerant piping

17.1.1 Refrigerant piping requirements

INFORMATION

Also read the precautions and requirements in the "General safety precautions"

chapter.

CAUTION

Piping MUST be installed according to instructions given in "17 Piping

installation" [4 61]. Only mechanical joints (e.g. braze+flare connections) that are

compliant with the latest version of ISO14903 can be used.

NOTICE

The piping and other pressure-containing parts shall be suitable for refrigerant. Use

phosphoric acid deoxidised seamless copper for refrigerant.

▪ Foreign materials inside pipes (including oils for fabrication) must be

≤30mg/10m.

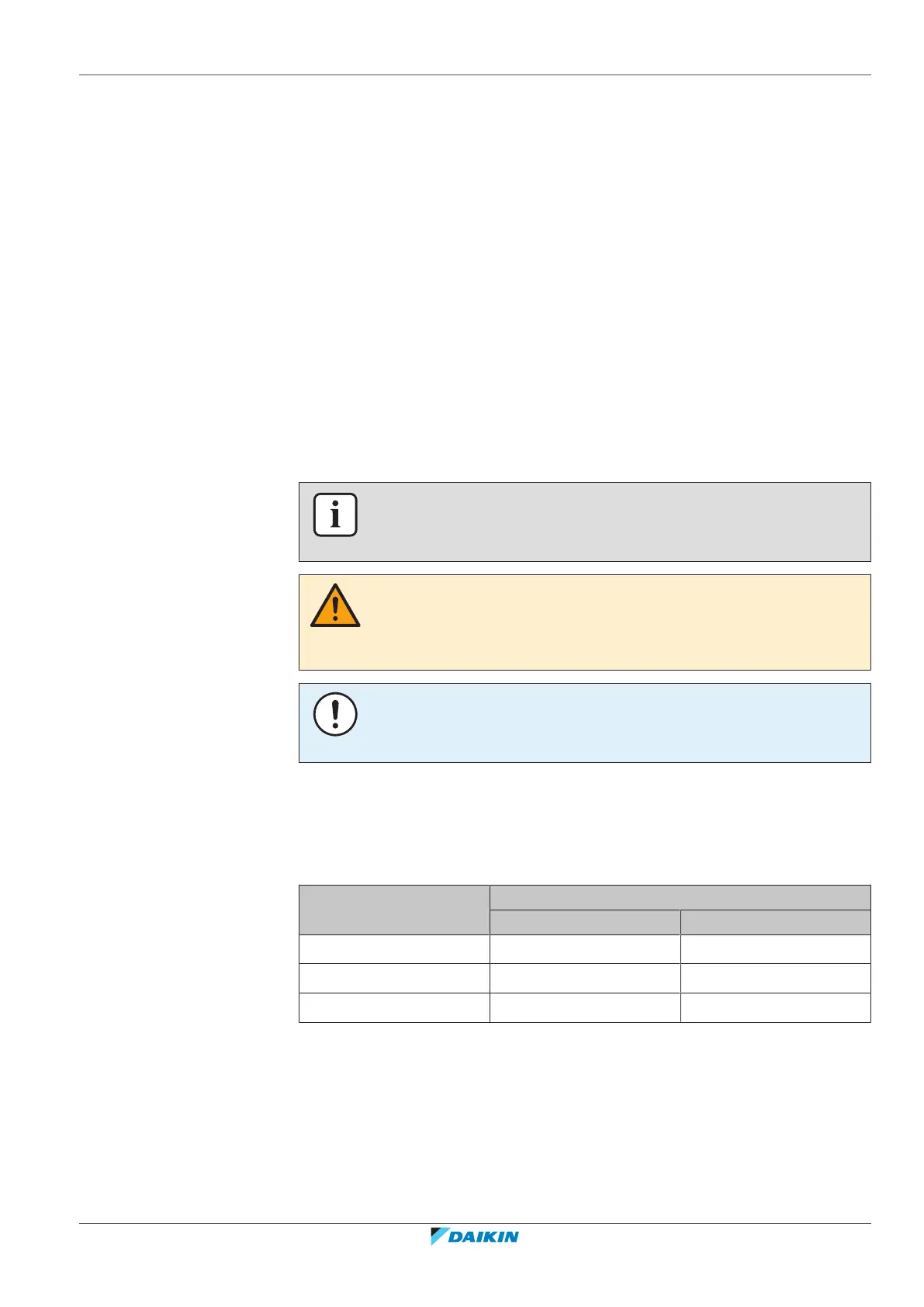

Refrigerant piping diameter

For piping connections of the indoor unit use the following piping diameters:

Class Pipe outer diameter (mm)

Liquid pipe Gas pipe

20~32 Ø6.4 Ø9.5

40~80 Ø6.4 Ø12.7

100~125 Ø9.5 Ø15.9

Refrigerant piping material

▪ Piping material: Phosphoric acid deoxidised seamless copper.

▪ Flare connections: Only use annealed material.

▪ Piping temper grade and thickness:

Loading...

Loading...